Method for preparing magnetic Nano composite granules coated by cationic polyelectrolyte

A technology of magnetic nanoparticles and cationic polymerization, which is applied in the field of preparation in the field of nanotechnology, can solve the problems that the magnetic particles cannot be uniformly coated, the magnetic particles cannot be uniformly dispersed, and the dispersion system cannot be obtained, and achieves wide application value. , Conducive to the effect of adsorption and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

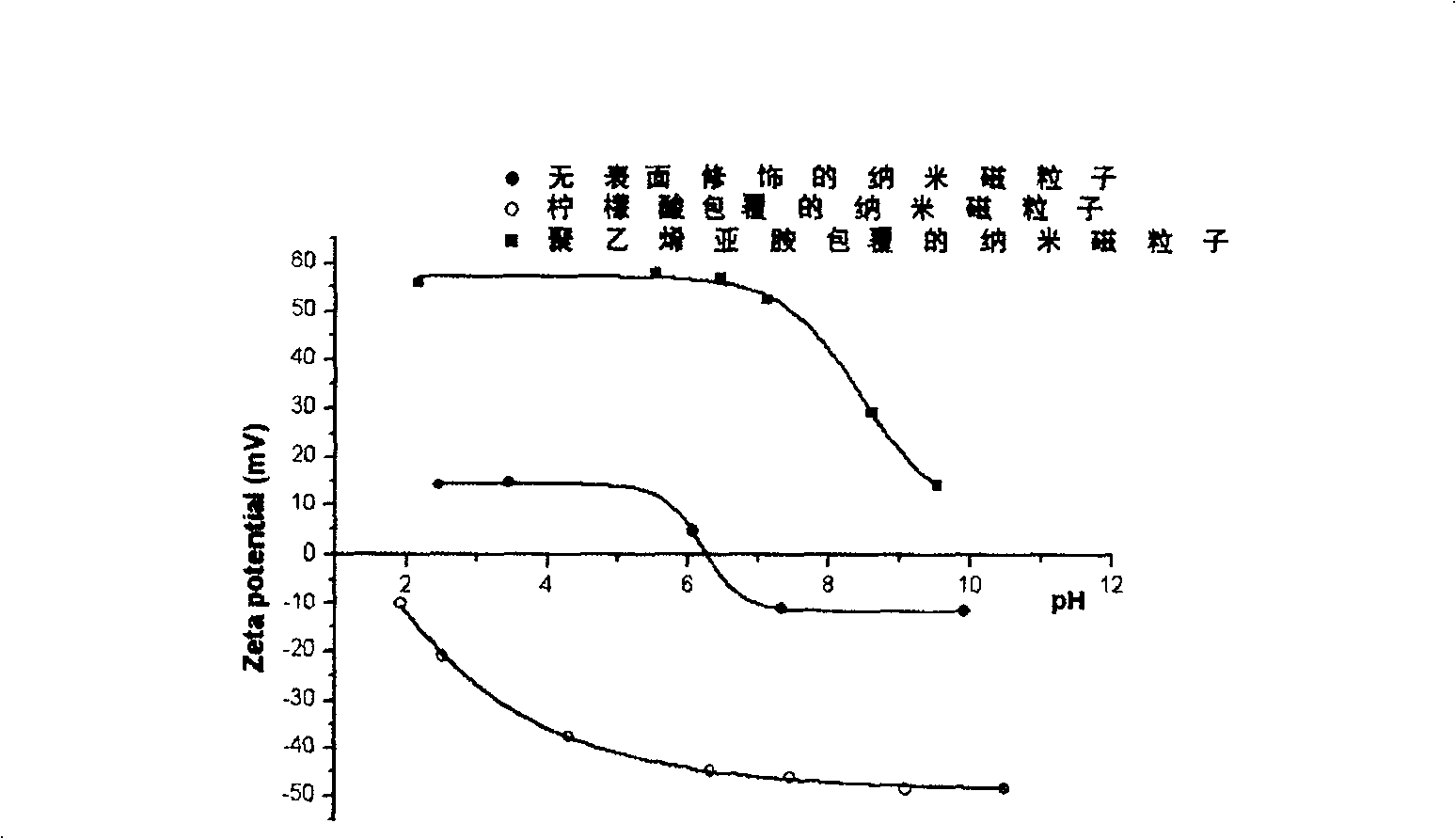

[0020] 2.4 grams of ferric chloride hexahydrate and 1.68 grams of ferrous sulfate heptahydrate are dissolved in 10 milliliters of water. Then slowly add 5 milliliters of ammoniacal liquor (25%) dropwise under stirring to produce black precipitate rapidly. After the ammoniacal liquor is added dropwise, The temperature of the reaction system was raised to 80° C., and the reaction was carried out under stirring and nitrogen protection for 1 hour. Then the product was washed with deionized water to neutrality to obtain ferric oxide particles with an average particle diameter of 10 nm, and its surface zeta potential in water was as shown in the accompanying drawing. Add the freshly prepared water-carrying particles into 80 ml of water, then add 1.6 g of citric acid monohydrate, stir for 5 minutes, and disperse with ultrasound for 20 minutes under ice water cooling. The pH of the product is adjusted to between 6.8 and 7.2 with 0.5 mol per liter of sodium hydroxide solution to obtain...

Embodiment 2

[0022] According to the method described in Example 1, the difference is that 2.5 g of oxalic acid is used instead of 1.6 g of citric acid monohydrate. Add oxalic acid, stir for 5 minutes, and disperse by ultrasonic for 40 minutes under ice water cooling. Subsequent steps are the same as in Example 1.

[0023] As a result, a water-based dispersion liquid was also prepared, containing 6-10 mg / ml of polyethyleneimine-coated magnetic nano-ferric oxide particles.

Embodiment 3

[0025] 12 grams of ferric chloride hexahydrate and 8.4 grams of ferrous sulfate heptahydrate are dissolved in 50 milliliters of water. Then slowly add 25 milliliters of ammoniacal liquor (25%) dropwise under stirring, and black precipitate is produced rapidly, after the ammoniacal liquor is added dropwise, The temperature of the reaction system was raised to 80° C., and the reaction was carried out under stirring and nitrogen protection for 1 hour. Then the product was washed with deionized water until neutral to obtain ferric oxide particles with an average particle diameter of 10 nanometers. After the particles were freeze-dried, 1 g was taken out and added to 20 ml of water, and then 2 g of acetic acid was quickly added, stirred for 5 minutes, and then dispersed by ultrasound for 40 minutes under ice water cooling. The pH of the product is adjusted to between 6.8 and 7.2 with 0.1 mole per liter of sodium hydroxide solution to obtain a stable ferriferric oxide dispersion. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com