Electrochromic film and preparation method and equipment thereof

An electrochromic and thin-film technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of slow color conversion, cracking and shedding of thin film layers, achieve good matching and durability, reduce pollution time, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

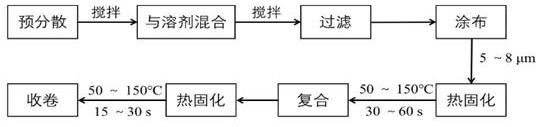

[0024] Please refer to figure 1 , a method for preparing an electrochromic thin film provided in an embodiment of the present invention, which includes the following steps:

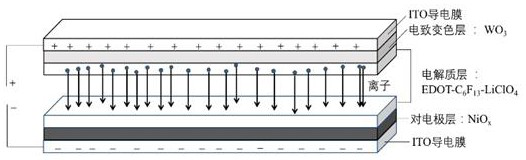

[0025] S1, select the substrate, and prepare amorphous WO on the substrate by magnetron sputtering method 3 Thin film and nanocrystalline NiO x film. It should be noted that, optionally, there are two substrates, both of which are ITO transparent conductive films.

[0026] S2. Put EDOT-C 6 f 13 -LiClO 4 Predispersed in a solvent to obtain a predispersed solution. It should be noted that, further specifically, wherein, EDOT refers to 3,4-ethylenedioxythiophene; the solvent is methanol, xylene, acetonitrile, toluene, ethyl acetate, acetone, butanone and methyl isobutyl ketone One or several mixtures in any proportion. In addition, in order to ensure the good dispersion effect and solute performance of the pre-dispersion solution, in the embodiment of the present invention, when performing pre-disper...

Embodiment 1

[0037] This embodiment provides a method for preparing an electrochromic thin film, which includes the following steps:

[0038] S1. Select ITO transparent conductive film as the substrate, and prepare amorphous WO on the substrate by magnetron sputtering method. 3 Thin film and nanocrystalline NiO x film.

[0039] S2. Put EDOT-C 6 f 13 -LiClO 4 Predispersed in a solvent to obtain a predispersed solution. Among them, the solvent is methanol; EDOT-C 6 f 13 -LiClO 4 The mass ratio of solvent and solvent is 92:8.

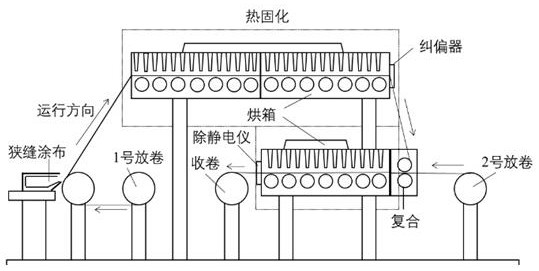

[0040] S3. After filtering the pre-dispersed solution, apply it to WO by slit coating method 3 film, after one thermal curing with NiO x The film is compounded, and then the electrochromic film is obtained after secondary thermal curing. It should be noted that after filtering the pre-dispersed solution, it is coated on WO by slit coating method. 3 film, the WO 3 The first electrolyte layer is formed on the film; with NiO x Thin films are composited on NiO...

Embodiment 2

[0044] This embodiment provides a method for preparing an electrochromic thin film, which includes the following steps: S1. Select an ITO transparent conductive film as a substrate, and prepare amorphous WO on the substrate by magnetron sputtering. 3 Thin film and nanocrystalline NiO x film.

[0045] S2. Put EDOT-C 6 f 13 -LiClO 4 Predispersed in a solvent to obtain a predispersed solution. Among them, the solvent is xylene and acetonitrile; EDOT-C 6 f 13 -LiClO 4 The mass ratio of solvent and solvent is 92:8.

[0046] S3. After filtering the pre-dispersed solution, apply it to WO by slit coating method 3 film, after one thermal curing with NiO x The film is compounded, and then the electrochromic film is obtained after secondary thermal curing. It should be noted that after filtering the pre-dispersed solution, it is coated on WO by slit coating method. 3 film, the WO 3 The first electrolyte layer is formed on the film; with NiO x Thin films are composited on NiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com