Coal feeding prevention device for roller bearing of coal conveying belt

A technology for rollers and bearings, applied in shafts and bearings, bearing components, transportation and packaging, etc., can solve the problems of coal powder entering and affecting the service life of roller bearings, and achieve the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

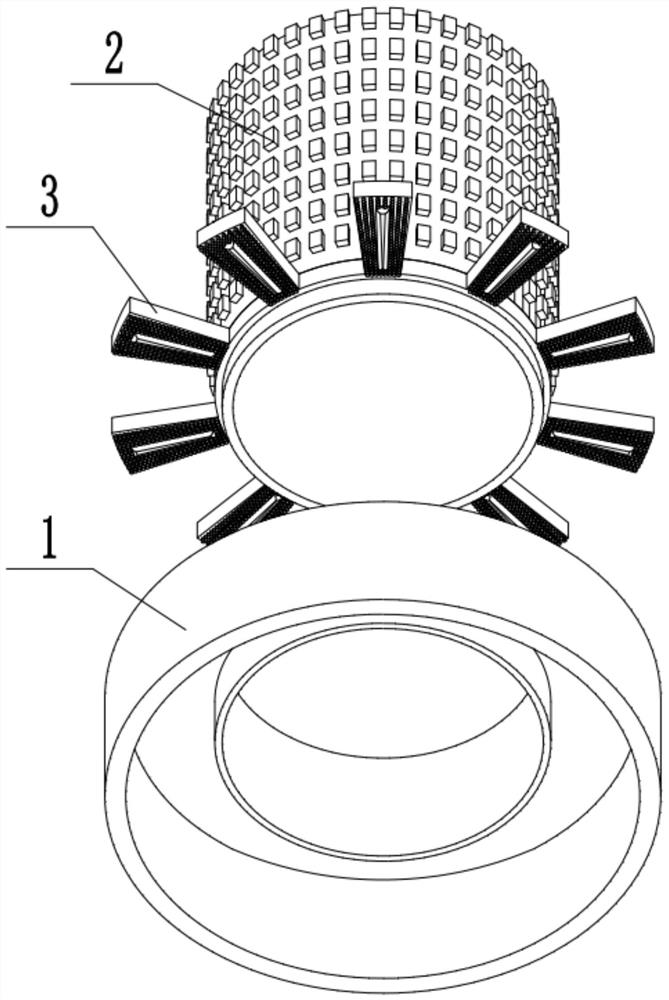

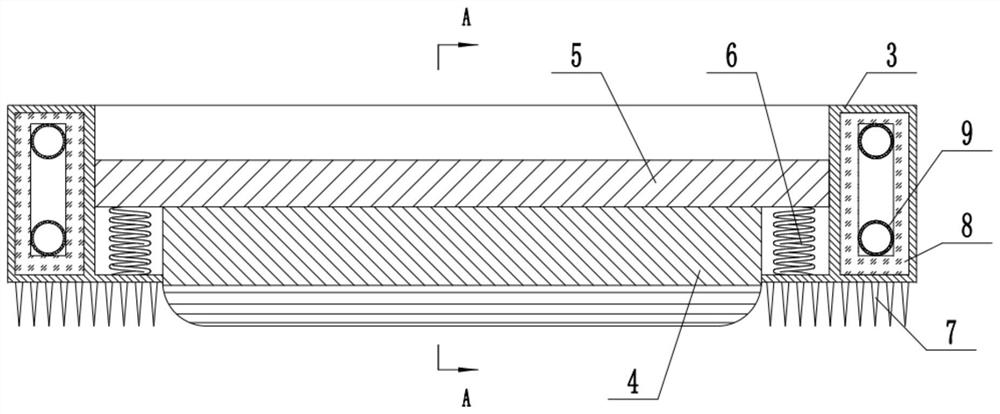

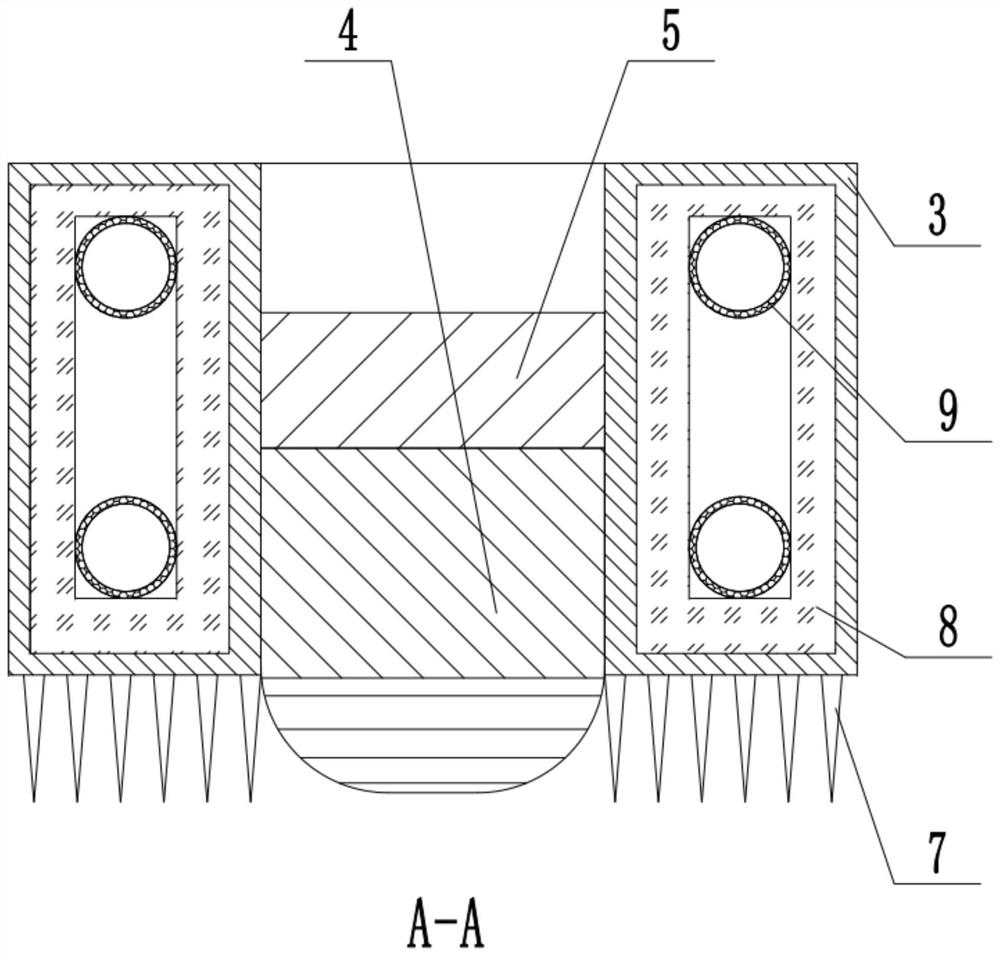

[0022] The reference signs in the drawings of the description include: wear-resistant partition 1, sleeve 2, brush plate 3, push block 4, push plate 5, spring 6, brush 7, friction gasket 8, ball 9, arc groove 10.

[0023] A coal conveying belt roller bearing anti-coal ingress device, for example figure 1 As shown: it includes a wear-resistant partition 1 that is rotatably connected to the drive shaft and can cover one end of the roller bearing, and a sleeve 2 that can be fixed on the shaft. Specifically, the sleeve 2 is keyed to the drive shaft, and the sleeve 2 There are dust-absorbing pads on the surface, and a number of brush plates 3 are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com