A swivel track-changing crane

A technology of cranes and swivels, which is applied in the direction of cranes, trolley cranes, mechanical equipment, etc., can solve the problems of reducing friction, cable breakage, wear, etc., and achieve the effects of reducing wear, increasing service life, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

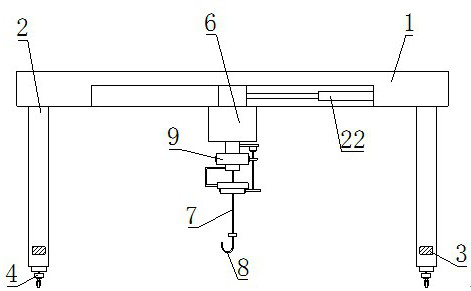

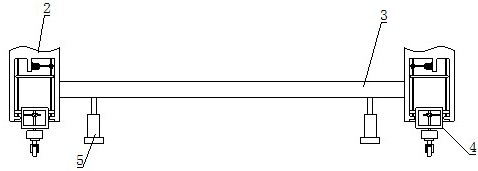

[0037] Such as Figure 1-9 As shown, a kind of swivel rail changing crane that the present invention proposes comprises main beam 1, support beam 2, longitudinal beam 3, steel cable 7, suspension hook 8 and push-pull cylinder 22, and the bottom of main beam 1 is fixedly installed with bolt Four sets of supporting beams 2 and longitudinal beams 3 are fixedly connected to two supporting beams 2 on the same side by bolts. The supporting beams 2 support the crane. Jacks 5 are installed on the bottom of the longitudinal beams 3, and the jacks 5 are used to lift the longitudinal beams 3. The bottom of the support beam 2 is equipped with a steering traveling mechanism 4, which is used for the walking of the crane. The steering traveling mechanism 4 includes a driving box 401, an electric traveling wheel 402, a steering shaft 403, an electric push rod 404, and a first rack 405 , the first gear 406 and the fixed block 407; the drive box 401 is arranged on the bottom of the support beam...

Embodiment 2

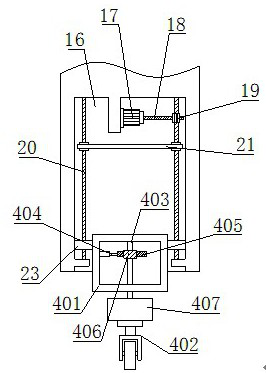

[0042] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bottom of the support beam 2 is provided with a storage slot 16, and a second drive motor 17 is fixedly installed in the storage slot 16 through a motor seat; the storage slot 16 is rotated by a bearing. There are many sets of studs 20, each stud 20 is provided with a sprocket, each stud 20 is connected by transmission chain 21, and the transmission chain 21 drives each stud 20 to rotate synchronously; the output end of the second driving motor 17 is installed There is a worm 18, and the second drive motor 17 is used to drive the worm 18, wherein a set of studs 20 is provided with a worm gear 19, the worm 18 is meshed with the worm gear 19, and the worm 18 drives the worm gear 19 to rotate; the outer wall of the drive box 401 is fixed by bolts There are many sets of moving blocks 23 installed, the moving blocks 23 correspond to the studs 20 one by one, and the moving blocks...

Embodiment 3

[0044] Such as Figure 10-12 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer peripheral surface of the standpipe 901 is fixed with a fixed bracket 15 by bolts, and the other end of the fixed bracket 15 is fixedly connected to the cleaning mechanism 10 by bolts. The surface of the cable 7 is cleaned to remove the dust particles on the surface of the cable 7, which is helpful for the subsequent lubrication operation, and also helps to reduce the friction force received by the cable 7 when it moves, and reduces the impact on the cable 7 due to friction. damage; the cleaning mechanism 10 includes a fixed ring 1001, a rotating ring 1002, a second external gear ring 1003, an arc-shaped mouth 1004, a slide bar 1005, a cleaning brush 1006, a pin rod 1007 and a limit slot 1008; the fixed ring 1001 and the fixed Support 15 is fixedly connected, and rotating ring 1002 is arranged on the bottom of fixed ring 1001. Multiple sets of limit slots 1008, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com