Control system and filling method of 25L square barrel weighing type automatic filling machine

A control system and filling machine technology, applied in the safety device of the filling device, barrel/cask filling, packaging, etc., can solve the problems of difficulty in ensuring precision control, waste, material leakage, etc., to improve work efficiency and improve filling. The effect of loading efficiency and avoiding material exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

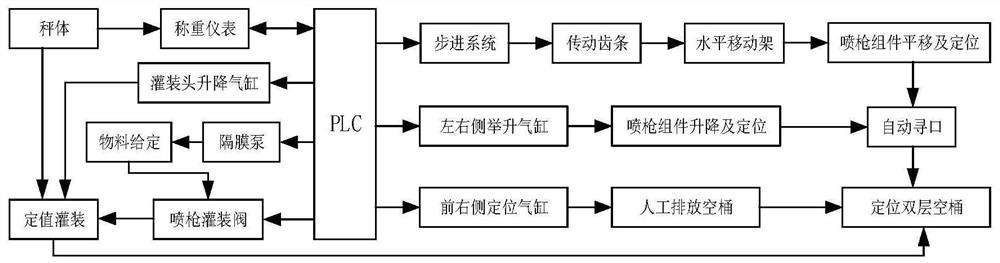

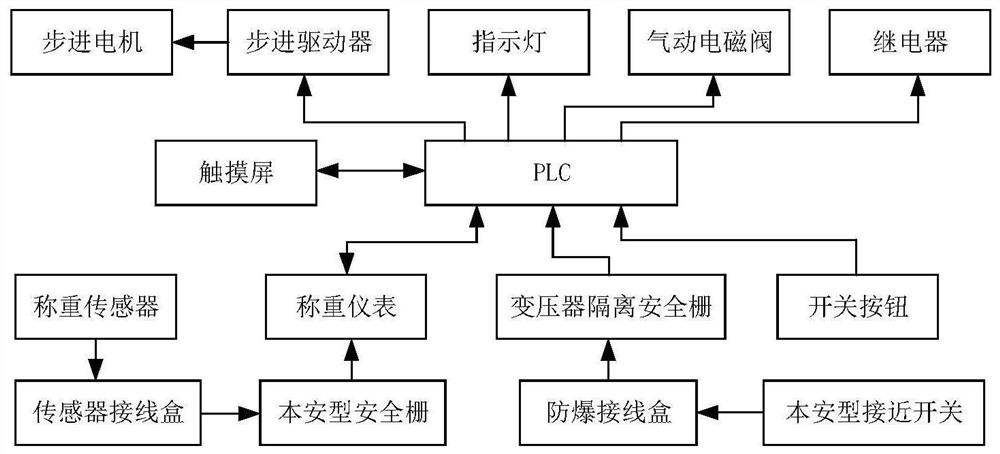

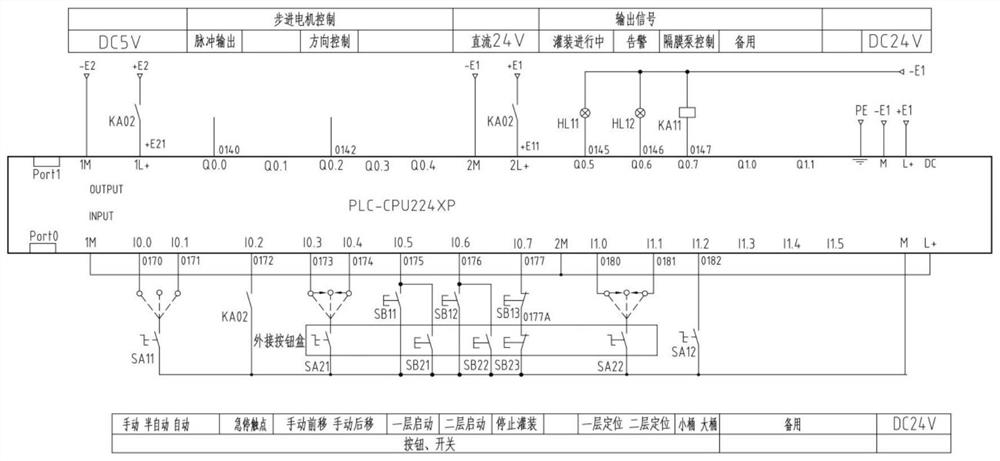

[0051] A 25L square barrel weighing type automatic filling machine control system, including: equipment rack, double-layer filling barrel, weighing scale, material setting unit, spray gun assembly moving unit, double-layer filling barrel positioning unit, positive Pressure control cabinet, pneumatic control box, PLC and touch screen.

[0052] In the present embodiment, the 25L square barrel is a known product in the art.

[0053] The equipment frame is used to carry various unit parts; the equipment frame is made of welded steel, and the equipment frame supports and frames the components of the filling machine.

[0054] In this embodiment, a mobile bracket is installed on the equipment rack, and the mobile bracket moves up and down relative to the equipment rack. At the same time, the mobile bracket is also provided with a horizontally movable beam for installing the mobile unit of the spray gun assembly, and the horizontally moved beam moves back and forth horizontally on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com