Preparation method of organic soil for high-temperature-resistant water-in-oil drilling fluid

A water-in-oil drilling fluid, high temperature resistance technology, applied in drilling compositions, chemical instruments and methods, inorganic chemistry, etc. The effect of stick-shear and high-temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

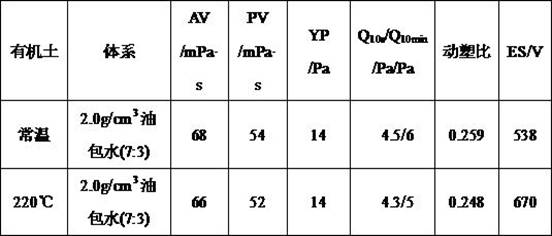

Examples

Embodiment 1

[0033] Disperse 50 parts of sodium-based soil into 700 parts of deionized water, stir at high speed to obtain a stable suspension, adjust the pH value of the suspension to 7~8, and set aside; chlorinate 20 parts of 1-octadecenetrimethyl Dissolve ammonium in 300 parts of deionized water and stir evenly to make it a clear and transparent solution for later use. Dissolve 10 parts of chelating agent in 100 parts of deionized water, stir evenly, and make it a clear and transparent solution for later use. Under high-speed stirring, quickly add 1-octadecenetrimethylammonium chloride solution to the suspension, react at 75°C for 1.5 hours, continue to add chelating agent, and stir for 1 hour. The product was cooled to room temperature, the residual Cl- in the product was repeatedly removed with deionized water, filtered, and the prepared organobentonite was vacuum-dried at 70°C, crushed and passed through a 200-mesh sieve to obtain the organobentonite product.

Embodiment 2

[0035] Disperse 60 parts of sodium-based soil into 800 parts of deionized water, stir at high speed to obtain a stable suspension, adjust the pH value of the suspension to 7~8, and set aside; chlorinate 22 parts of 1-octadecenetrimethyl Dissolve ammonium in 200 parts of deionized water and stir evenly to make it a clear and transparent solution for later use. Dissolve 8 parts of chelating agent in 100 parts of deionized water, stir evenly, and make it a clear and transparent solution for later use. Under high-speed stirring, quickly add 1-octadecenetrimethylammonium chloride solution to the suspension, react at 70°C for 1.5 hours, continue to add chelating agent, and stir for 1 hour. The product was cooled to room temperature, the residual Cl- in the product was repeatedly removed with deionized water, filtered, and the prepared organobentonite was vacuum-dried at 75°C, crushed and passed through a 200-mesh sieve to obtain the organobentonite product.

Embodiment 3

[0037] Disperse 65 parts of sodium-based soil into 800 parts of deionized water, stir at high speed to obtain a stable suspension, adjust the pH value of the suspension to 7~8, and set aside; chlorinate 24.8 parts of 1-octadecenetrimethyl Dissolve ammonium in 200 parts of deionized water and stir evenly to make it a clear and transparent solution for later use. Dissolve 9 parts of chelating agent in 100 parts of deionized water, stir evenly, and make it a clear and transparent solution for later use. Under high-speed stirring, quickly add 1-octadecenetrimethylammonium chloride solution to the suspension, react at 70°C for 1.5 hours, continue to add chelating agent, and react for 1 hour. The product was cooled to room temperature, the residual Cl- in the product was repeatedly removed with deionized water, filtered, and the prepared organobentonite was vacuum-dried at 70°C, crushed and passed through a 200-mesh sieve to obtain the organobentonite product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com