Preparation formula, preparation method and special preparation equipment of synthetic rubber tube for air inlet and outlet of intercooler meeting national sixth emission standard

An emission standard and intercooler technology, which is applied in the formulation and preparation of synthetic rubber hoses for intercooler air inlet and outlet, can solve problems such as poor bonding effect, reduce the risk of failure, good processing fluidity, and good adhesion The effect of connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

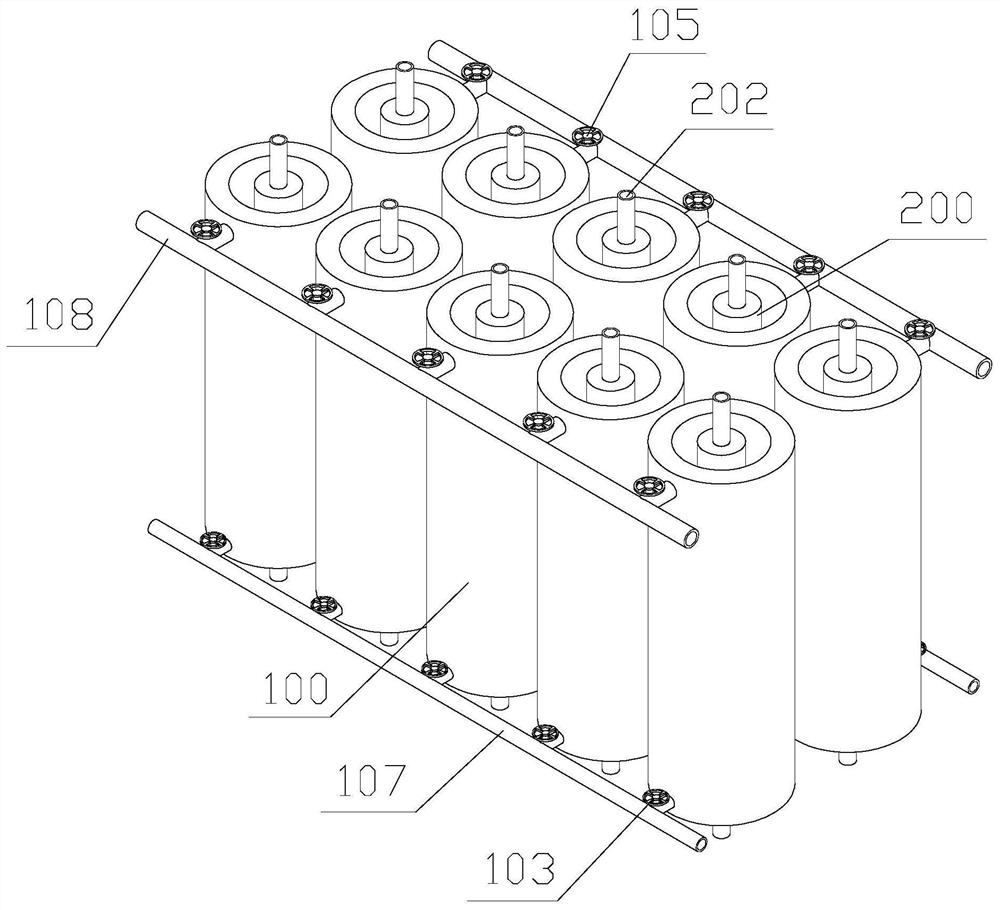

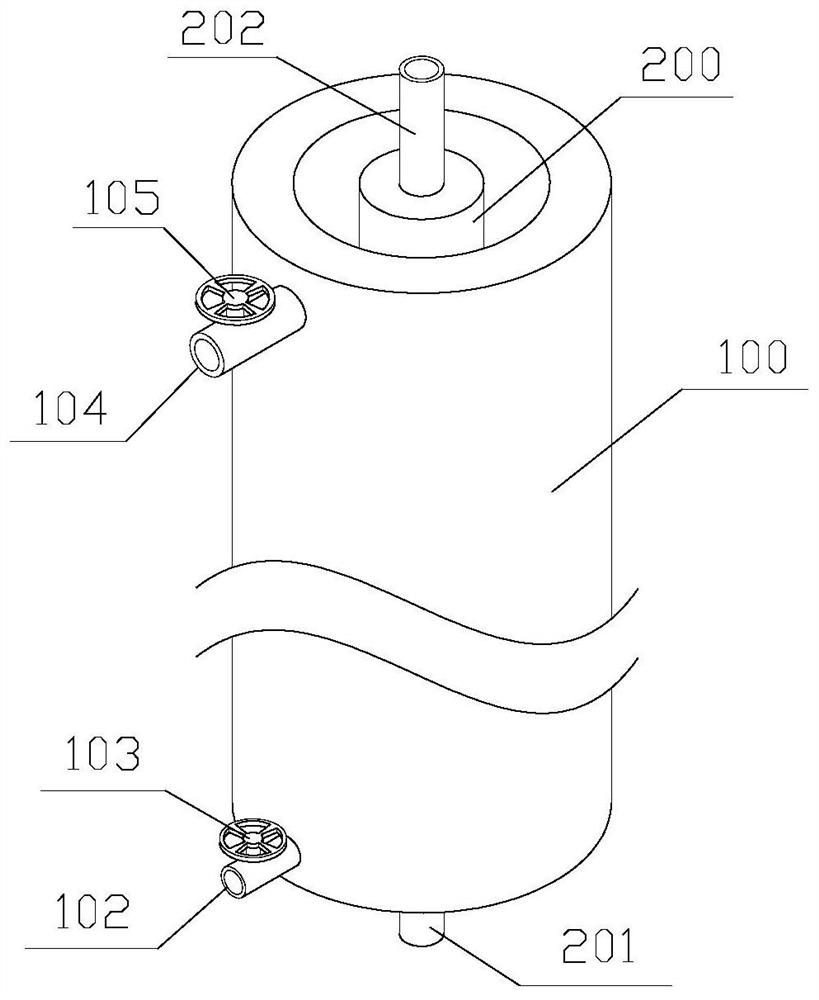

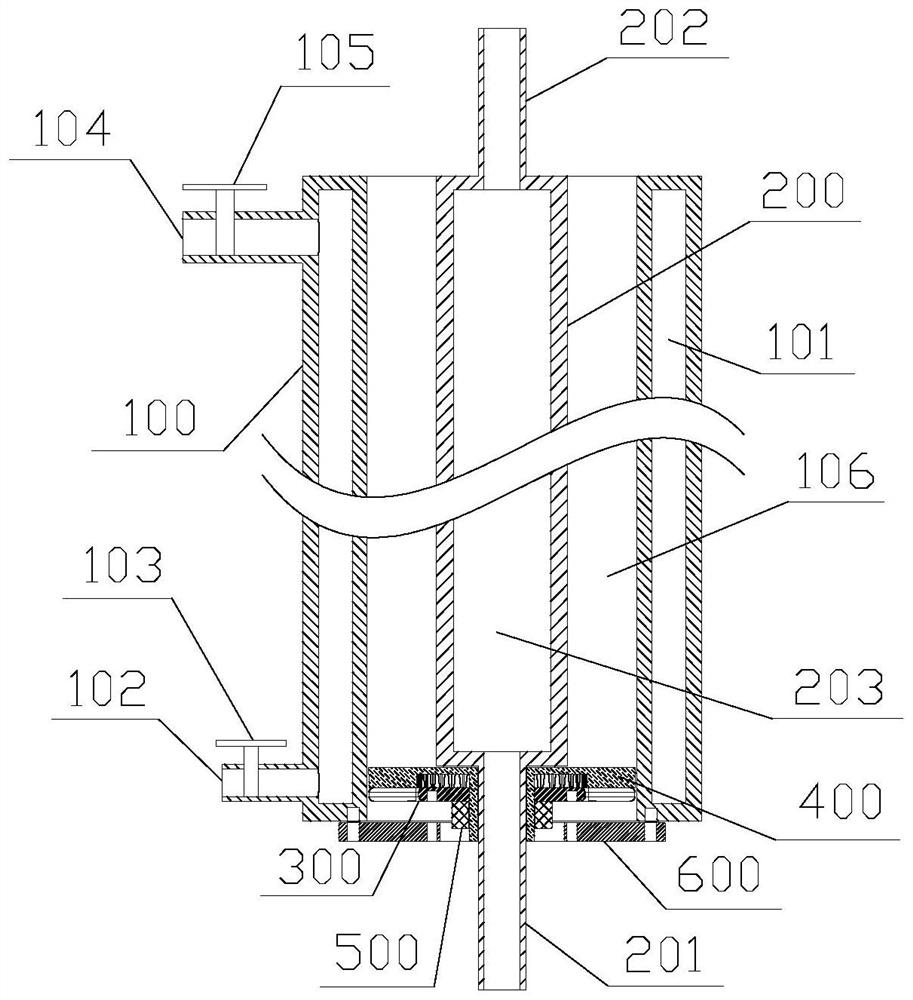

[0034] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

[0035] The invention discloses a preparation formula of a synthetic rubber hose for the inlet and outlet of an intercooler that satisfies the National VI emission standard. Calcium oxide 6-11 parts, tackifier 2-5 parts, odorless DCP 1-2 parts, high wear-resistant carbon black 38-60 parts, plasticizer 3-5 parts, barium sulfate 8-12 parts. The working principle and advantages of the present invention are: according to this formula, the fluororubber (FKM) with high adhesive properties) and silicone rubber (VMQ) have a good adhesive effect, and under the hot air aging state of 220°C*168H , the bonding strength of fluororubber (FKM)) and silicone rubber (VMQ) is still > 0.5KN / m, which meets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com