Modified polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology, applied in the field of modified polypropylene composition, can solve the problems of limiting the application effect of polypropylene materials, poor weather resistance of polypropylene, embrittlement of flame-retardant polypropylene, etc., and achieve good processing fluidity , small creep, stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

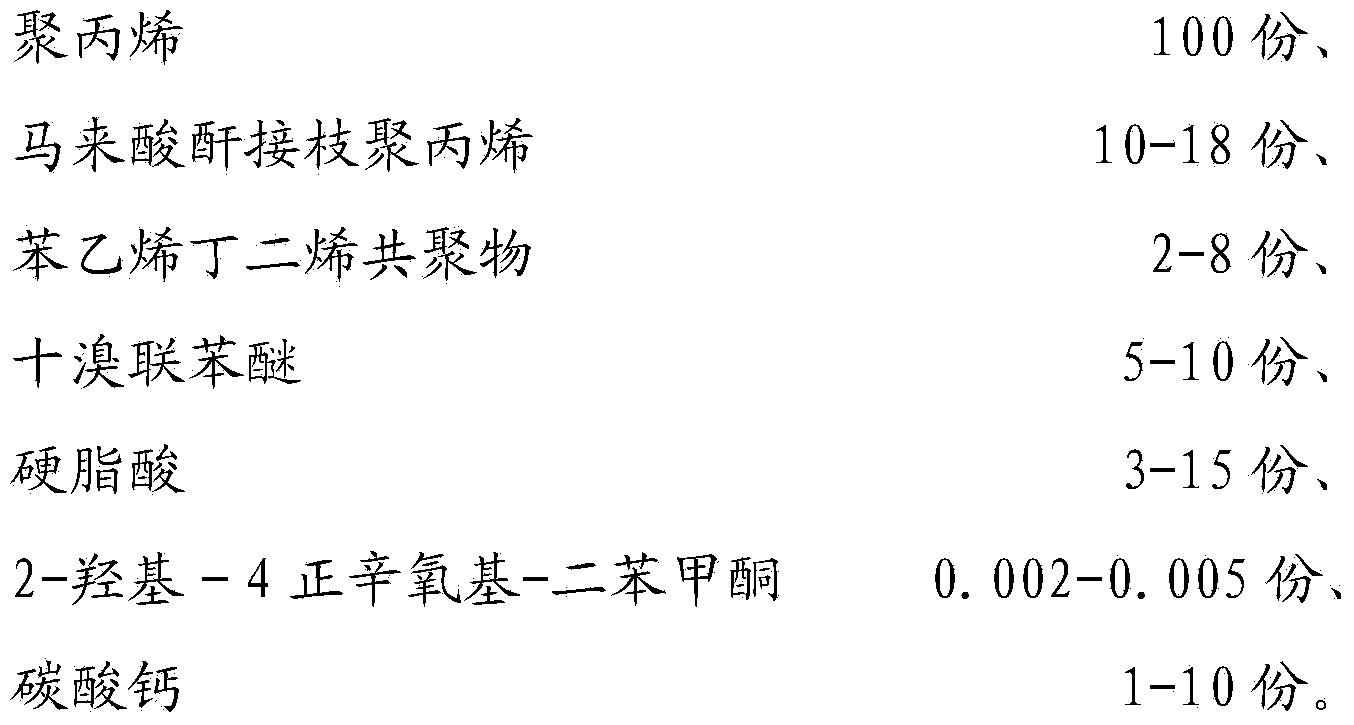

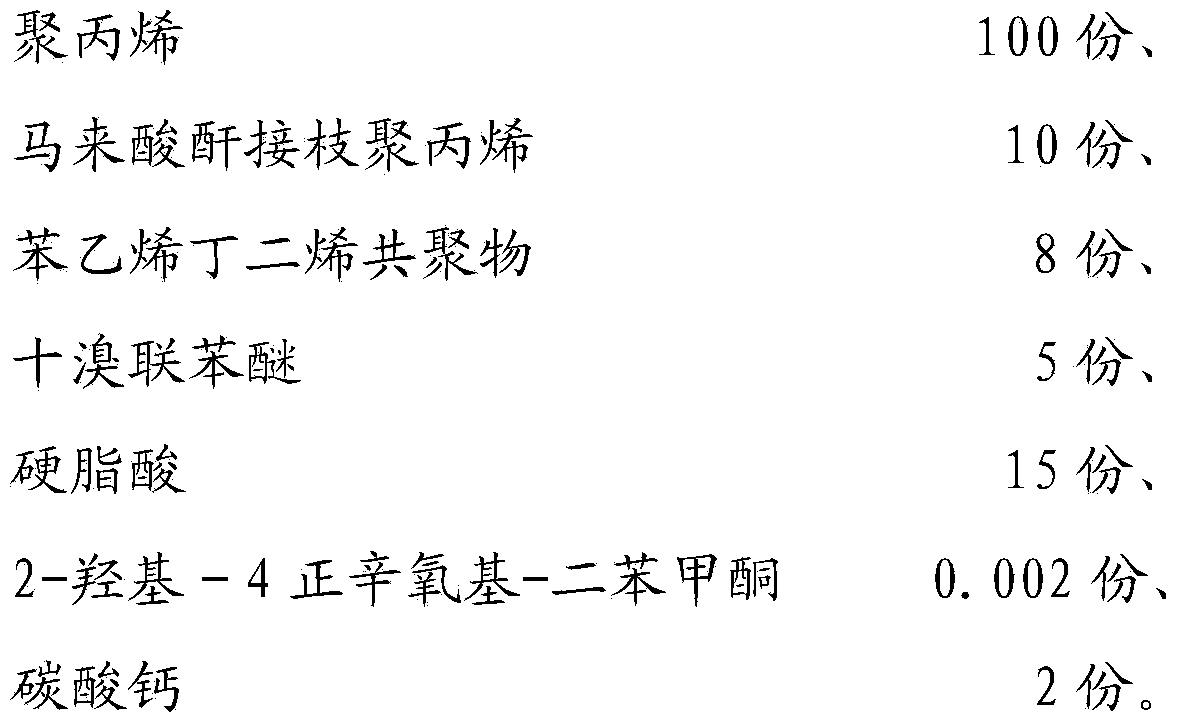

[0012] The parts by weight of each component are as follows:

[0013]

[0014] The average particle size of the calcium carbonate is 2 microns.

[0015] Polypropylene, maleic anhydride grafted polypropylene, styrene butadiene copolymer, decabromodiphenyl ether, stearic acid, 2-hydroxy-4 n-octyloxy-benzophenone, calcium carbonate in the above ratio Add it into a high-speed mixer, and the stirring speed is 1500 rpm, so that all components are fully mixed and evenly formed into a mixture;

[0016] Send the mixture into a twin-screw extruder for extrusion and granulation. The rotating speed is 350r / min. The temperature in the zone is 190°C, the temperature in the fifth zone is 195°C, and the modified polypropylene composition is obtained after extrusion.

Embodiment 2

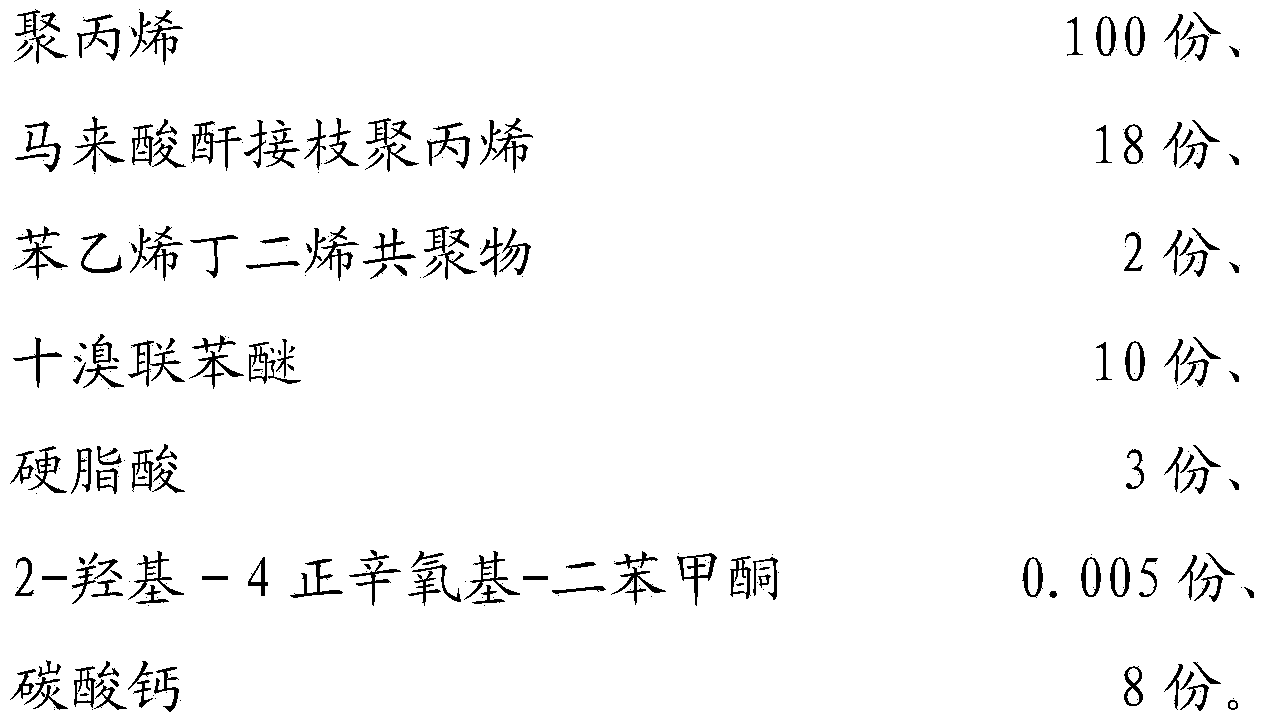

[0018] The parts by weight of each component are as follows:

[0019]

[0020] The calcium carbonate preferably has an average particle diameter of 5 microns.

[0021] Add polypropylene, maleic anhydride grafted polypropylene, styrene butadiene copolymer, decabromodiphenyl ether, stearic acid, 2-hydroxy-4 n-octyloxy-benzophenone, and calcium carbonate in proportion In the high-speed mixer, the stirring speed is 1500-2000 rpm, so that the components are fully mixed and evenly formed into a mixture;

[0022] Send the mixture into a twin-screw extruder for extrusion and granulation. The rotating speed is 420r / min. The temperature in the zone is 190°C, the temperature in the fifth zone is 195°C, and the modified polypropylene composition is obtained after extrusion.

[0023] The modified polyacrylic acid composition of the present invention has good flame retardancy, good processing fluidity, good molding performance, low creep and stable size; at the same time, it has better...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com