Carbon fiber reinforced PC resin composite material and preparation method and application thereof

A resin composite material, carbon fiber technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

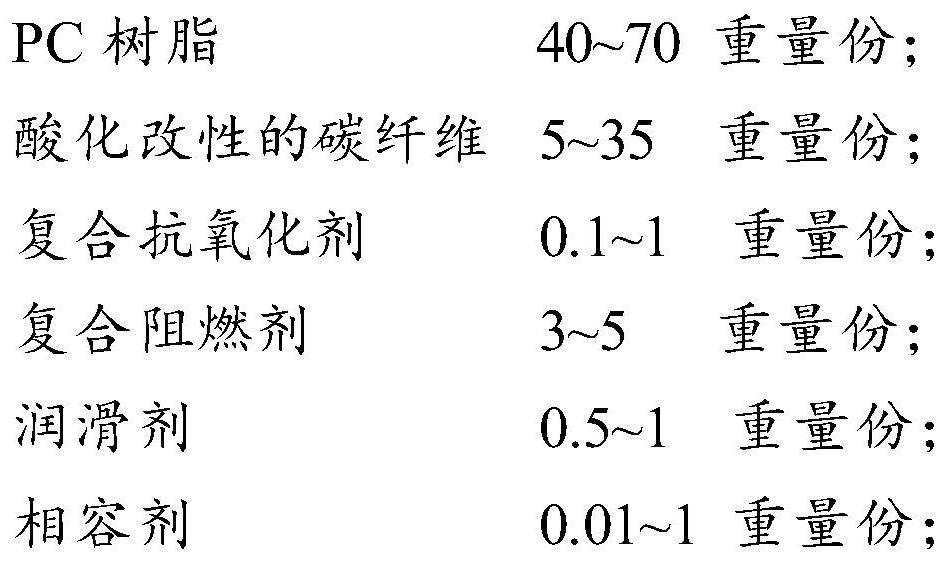

[0069] The invention provides a kind of preparation method of carbon fiber reinforced PC resin composite material, comprises the following steps:

[0070] 1) After mixing PC resin, compatibilizer, composite antioxidant, composite flame retardant and auxiliary agent, a mixed resin base material is obtained;

[0071] 2) extruding and granulating the mixed resin base material, acidified modified carbon fiber and lubricant obtained in the above steps to obtain a carbon fiber reinforced PC resin composite material.

[0072] In the invention, firstly, after mixing PC resin, compatibilizer, composite antioxidant, composite flame retardant and auxiliary agent, a mixed resin base material is obtained.

[0073] In the present invention, the mixed resin base material obtained in the above steps, the acidified modified carbon fiber and the lubricant are extruded and granulated to obtain a carbon fiber reinforced PC resin composite material.

[0074] In the present invention, the acidifie...

Embodiment 1

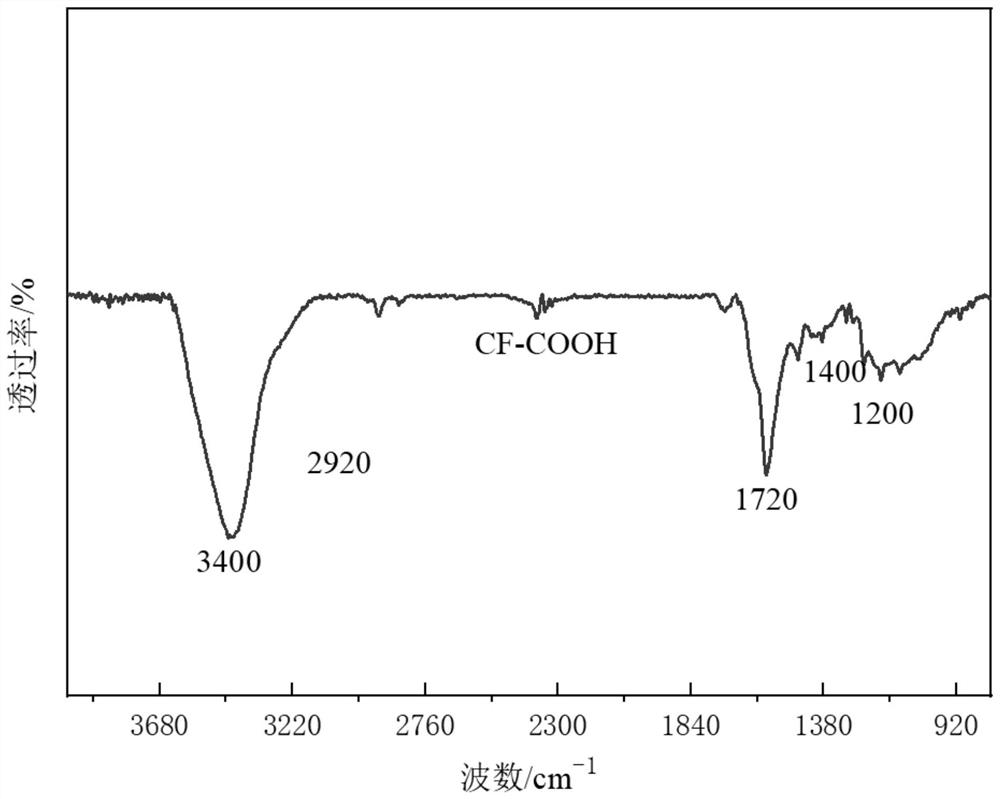

[0092] (1) Carbon fiber acidification treatment: put CF in a glass container, add a certain amount of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2:1) mixture, 60 ° C ultrasonic treatment for a period of time; then naturally cool the reaction solution to room temperature, Rinse CF several times with deionized water and dry to obtain acidified CF;

[0093] (2) 70% of PC, 0.5% of compatibilizer, 0.5% of composite antioxidant, 4% of composite flame retardant and 10% of additives are mixed uniformly to obtain a mixed resin base;

[0094](3) The modified carbon fiber after 10% acidification, 5% titanate coupling agent and the mixed resin base material in step (2) are added to the twin-screw extruder, through the twin-screw extruder at 220 Melt blending at ~250°C, extrusion and granulation to obtain carbon fiber composite material granules. During the extrusion process, the screw speed is 120r / min, the feeding speed is 15r / min, and the carbon fiber feeding...

Embodiment 2

[0103] (1) Carbon fiber acidification treatment: put CF in a glass container, add a certain amount of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2:1) mixture, 60 ° C ultrasonic treatment for a period of time; then naturally cool the reaction solution to room temperature, Rinse CF several times with deionized water and dry to obtain acidified CF;

[0104] (2) 60% of PC, 0.5% of compatibilizer, 0.5% of composite antioxidant, 4% of composite flame retardant and 10% of additives are mixed uniformly to obtain a mixed resin base;

[0105] (3) The modified carbon fiber after 20% acidification, 5% titanate coupling agent and the mixed resin base material in step (2) are added to the twin-screw extruder, through the twin-screw extruder at 220 Melt blending at ~250°C, extrusion and granulation to obtain carbon fiber composite material granules. During the extrusion process, the screw speed is 120r / min, the feeding speed is 15r / min, and the carbon fiber feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com