A kind of silk anti-wrinkle fabric and its preparation method

The technology of silk fabric and anti-wrinkle fabric is applied in the field of silk anti-wrinkle fabric and its preparation, which can solve the problems of low elastic recovery rate, low elasticity of silk fiber, poor wrinkle resistance and the like, and achieve the effect of increasing the wrinkle recovery angle and improving the wrinkle resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

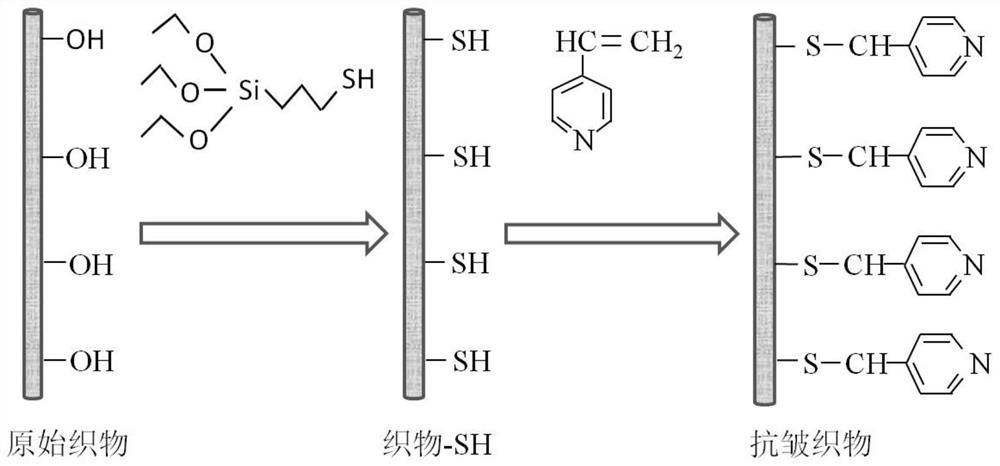

Method used

Image

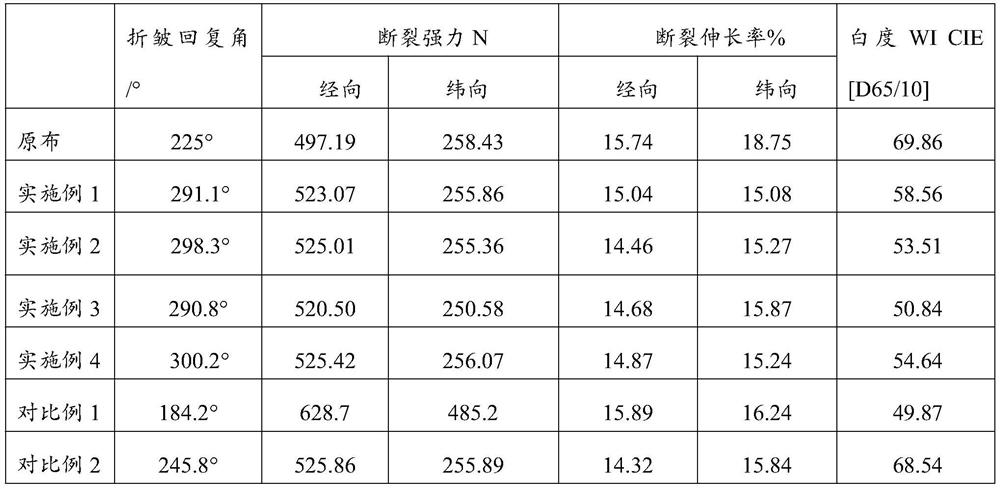

Examples

Embodiment 1

[0028] Step 1: Silk fabric pretreatment, experimental plan: silk fabric 10cm×10cm, 60°C, soap flakes 2g / L, NaHCO 3 5g / L, liquor ratio 1:50, boiled in water for 30min, and dried in vacuum at 60°C. Then use acetone, ethanol, and deionized water to clean with ultrasonic vibration, and use each solution to clean ultrasonically for 20 minutes. After cleaning, take out the cloth sample. Vacuum drying at 60°C.

[0029] Step 2: The surface modification method of the silk fabric is as follows: cut the pretreated silk fabric into a 5cm×5cm cloth sample, remove the burrs, add 3-mercaptopropyl triethoxysilane, 3-mercaptopropyl triethyl The oxysilane solvent is ethyl acetate, the mass percentage concentration of the solution is 2wt%, put it into an infrared dyeing machine at 50°C, take it out after reacting for 1h, wash it with ethanol, and dry it under vacuum at 60°C.

[0030] Step 3: The method of mercapto-ene click chemistry anti-wrinkle modified silk fabric: take out the silk fabric ...

Embodiment 2

[0032] Step 1: Silk fabric pretreatment, experimental plan: silk fabric 10cm×10cm, 60°C, soap flakes 2g / L, NaHCO 3 5g / L, liquor ratio 1:50, boiled in water for 30min, and dried in vacuum at 60°C. Then use acetone, ethanol, and deionized water to clean with ultrasonic vibration, and use each solution to clean ultrasonically for 20 minutes. After cleaning, take out the cloth sample. Vacuum drying at 60°C.

[0033] Step 2: The surface modification method of the silk fabric is as follows: cut the pretreated silk fabric into a 5cm×5cm cloth sample, remove the burrs, add 3-mercaptopropyl triethoxysilane, 3-mercaptopropyl triethyl The oxysilane solvent is ethyl acetate, the mass percentage concentration of the solution is 2wt%, put it into an infrared dyeing machine at 50°C, take it out after reacting for 1h, wash it with ethanol, and dry it under vacuum at 60°C.

[0034] Step 3: The method of mercapto-ene click chemistry anti-wrinkle modified silk fabric: take out the silk fabric ...

Embodiment 3

[0036] Step 1: Silk fabric pretreatment, experimental plan: silk fabric 10cm×10cm, 60°C, soap flakes 2g / L, NaHCO 3 5g / L, liquor ratio 1:50, boiled in water for 30min, and dried in vacuum at 60°C. Then use acetone, ethanol, and deionized water to clean with ultrasonic vibration, and use each solution to clean ultrasonically for 20 minutes. After cleaning, take out the cloth sample. Vacuum drying at 60°C.

[0037] Step 2: The surface modification method of the silk fabric is as follows: cut the pretreated silk fabric into a 5cm×5cm cloth sample, remove the burrs, add 3-mercaptopropyl triethoxysilane, 3-mercaptopropyl triethyl The oxysilane solvent is ethyl acetate, the mass percentage concentration of the solution is 2wt%, put it into an infrared dyeing machine at 50°C, take it out after reacting for 1h, wash it with ethanol, and dry it under vacuum at 60°C.

[0038] Step 3: The method of mercapto-ene click chemical anti-wrinkle modified silk fabric: take out the mercapto-conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com