Integrated air supplying and exhausting fan

A technology for supplying and exhausting air and fans, applied in the field of machinery, can solve the problems of increasing the number of air valves and fans in the pipeline, increasing the maintenance cost, complex structure, etc., and achieving the effects of convenient maintenance, simple structure, and flexible operation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

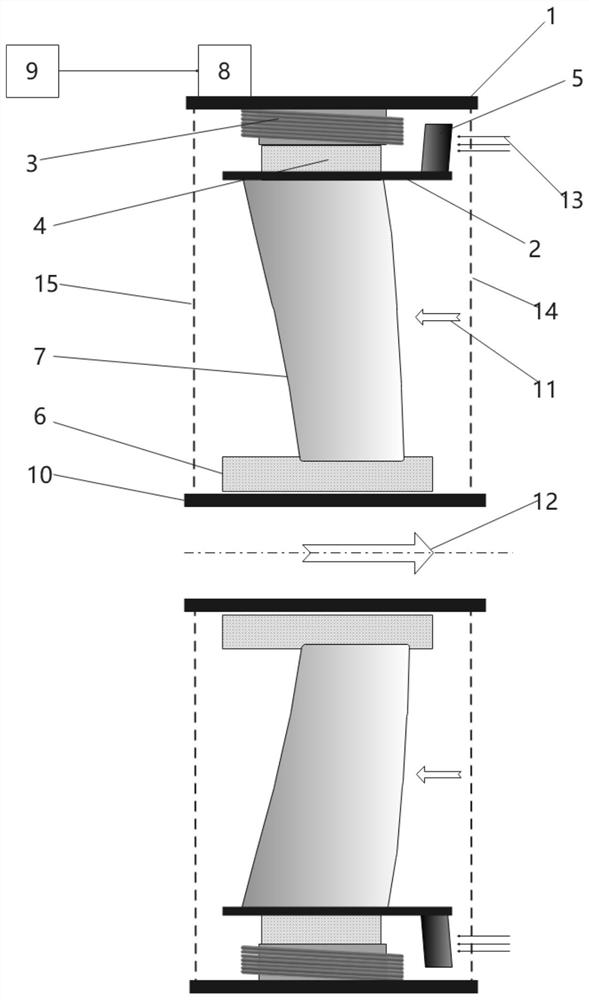

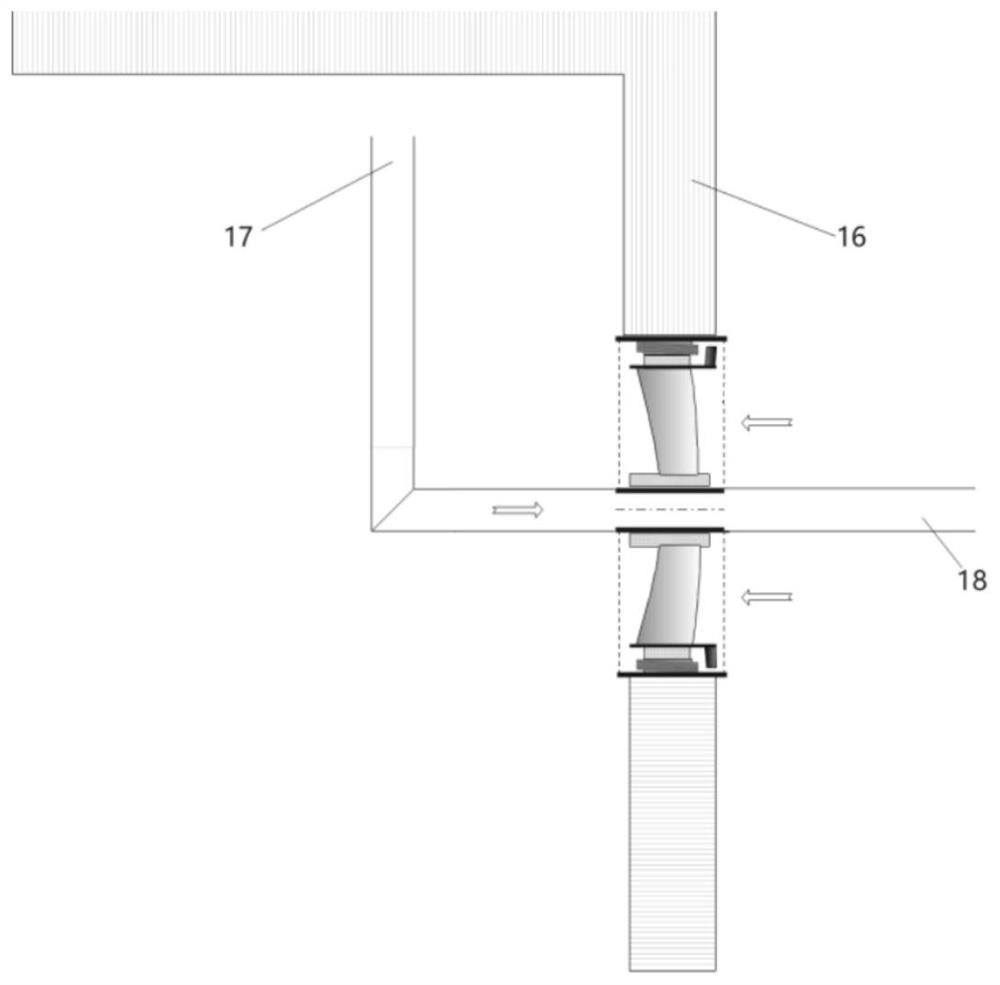

[0029] When it is necessary to create a positive pressure in the room, the fan is installed as image 3 As shown, the suction port connecting pipe 17 is connected to the air exhaust port connecting pipe 18 through the fan inner pipe 10, the outer casing 1 is fixed in the through hole on the wall 16 of the room of the structure, and the side between the outer casing 1 and the fan inner pipe 10 An air inlet protection net 14 is provided, and an air outlet protection net 15 is provided on the other side between the outer casing 1 and the fan inner pipe 10 .

[0030] When working, the fan blades 7 send air into the room, so that the room forms a positive pressure, and the positive pressure in the room makes the gas at the top of the room flow into the air inlet connecting pipe 17, and then enter the air outlet connecting pipe 18 through the fan inner pipe 10 In the middle, and finally out of the room, when working, this way of working can remove the light gas at the top of the roo...

Embodiment 2

[0032] When it is necessary to form a negative pressure in the room, the fan is installed as Figure 4 As shown, specifically, the air inlet connecting pipe 21 communicates with the air outlet connecting pipe 22 through the fan inner pipe 10, and the outer shell 1 is fixed in the through hole on the wall 16 of the room of the structure.

[0033] The gas in the room is discharged through the fan blades 7 to form a negative pressure, and the negative pressure in the room makes the outside air flow into the fan inner pipe 10 through the air inlet connecting pipe 21, and then enter the room through the air outlet connecting pipe 22.

Embodiment 3

[0035] When the fan is not conducive to being installed on the wall or needs to be moved, it can be used in conjunction with the sleeve-type air duct assembly. The fan inner pipe 19 in the sleeve-type air duct assembly is docked with the fan inner pipe 10. The installation of the fan and the sleeve like Figure 5 As shown, specifically, in the sleeve-type air duct assembly, the fan outer shell 20 is docked with the outer shell 1, the fan inner pipe 19 is docked with the fan inner pipe 10, and the sleeve-type air duct can be installed on both sides of the fan. Through the above-mentioned different configuration combinations, the positive and negative pressure control of the room can be realized, and the arrangement of air inlets or exhaust outlets at different positions in the room can also be realized, which has strong operational flexibility.

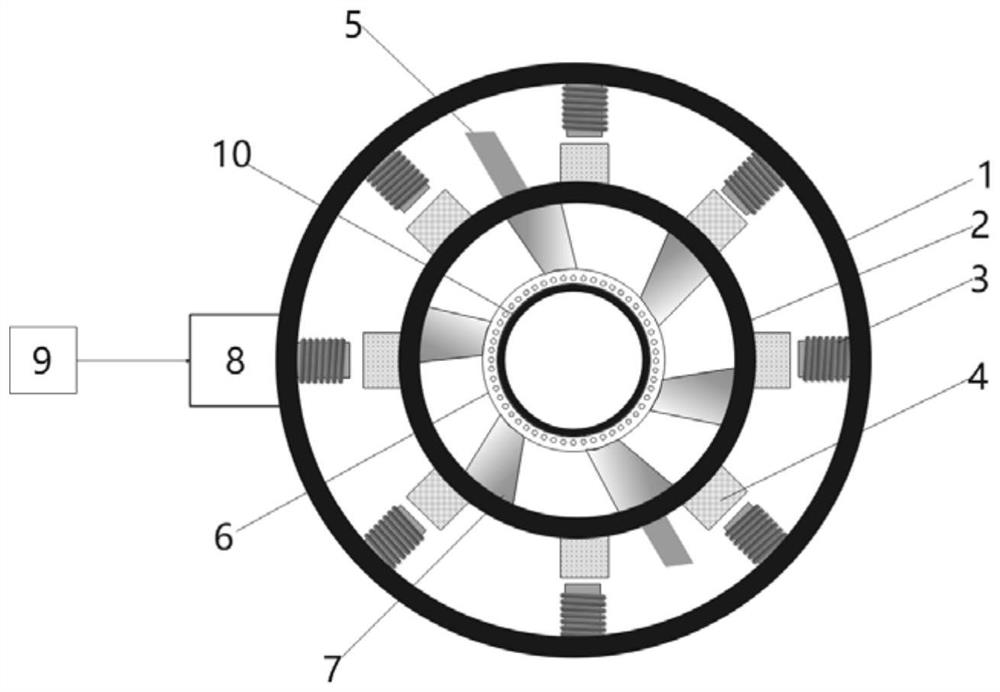

[0036] The power supply system 9 is connected to the stator core and the winding 3 through the junction box 8, and generates a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com