Electric power angle steel intelligent detection system and method based on image recognition

A technology of image recognition and intelligent detection, applied in measuring devices, instruments, optical devices, etc., can solve the problems of lack of large-scale popularization and application, difficulty in operation, economic loss, etc., to improve processing accuracy and measurement accuracy, guarantee Product quality, the effect of reducing production losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

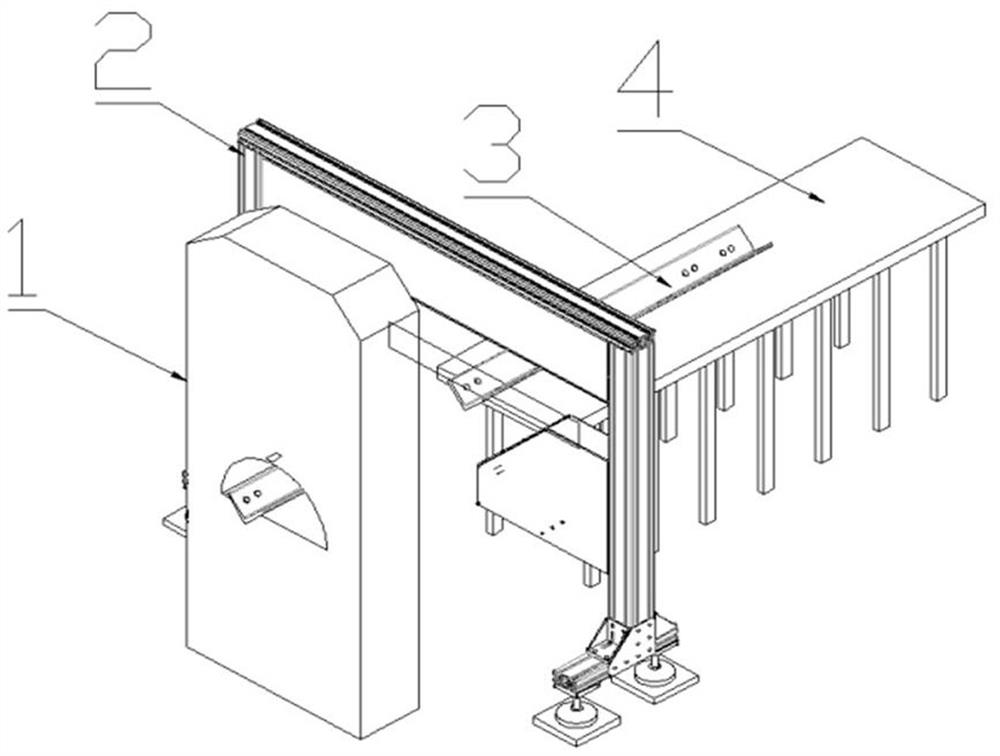

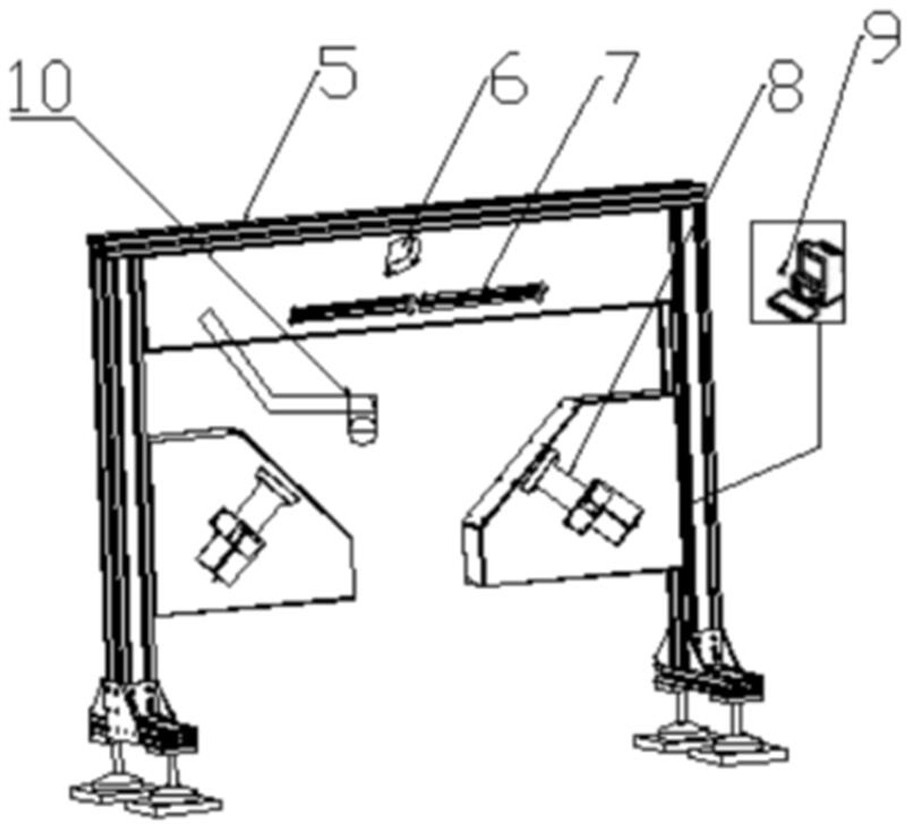

[0033] This embodiment discloses an intelligent detection system for electric power angle steel based on image recognition, such as figure 2 As shown, this system is set at the finished angle steel end under the premise of changing the angle steel processing line. figure 2 Including angle steel automatic processing equipment 1, intelligent angle steel detection system 2, angle steel 3 and angle steel transmission system 4. Angle steel automatic processing equipment 1 mainly refers to angle steel punching and cutting production line equipment. The angle steel 3 (finished product) after processing is automatically conveyed forward by the angle steel conveying device 4. The angle steel 3 enters the detection range of the intelligent angle steel detection system 2 and triggers 2 to work. The intelligent angle steel detection system 2 starts to collect the image data of the angle steel finished parts 3 entering the detection range until the angle steel transmission device 4 trans...

Embodiment 2

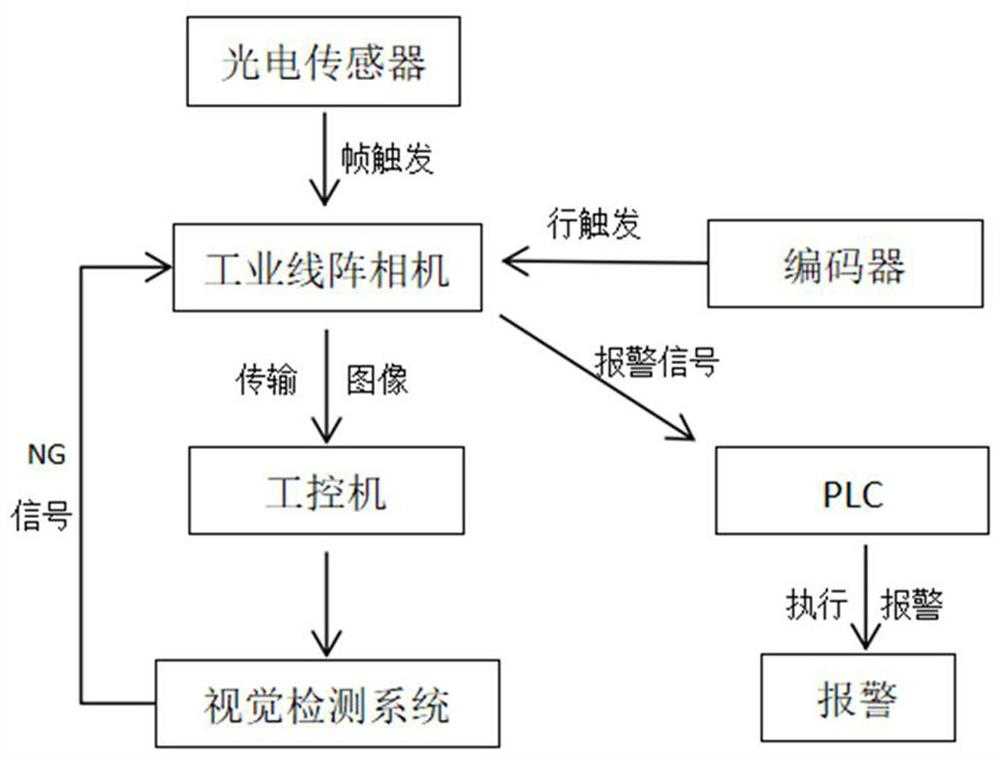

[0052] This embodiment discloses a method for intelligent detection of electric angle steel based on image recognition, such as figure 1 shown, including the following steps:

[0053] S01), the angle steel to be detected is conveyed, the raw material of the angle steel is pushed out by the feeding push rod structure after being processed by the punching and punching equipment, and enters the angle steel transmission device installed under the main bracket of the intelligent detection system;

[0054] S02), the triggering of the angle steel sensing device, when the angle steel transmission device transmits the angle steel to be detected to the sensing range of the angle steel sensing device, trigger the angle steel sensing device to work, start the working state of the photoelectric sensor and encoder and send out a signal;

[0055] S03), after the photoelectric sensor is triggered, it sends a signal to the industrial line array camera, so that the industrial line array camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com