Memristor for realizing shaping and positioning of conductive filament channel

A technology of conductive filaments and memristors, applied in the direction of electrical components, etc., can solve the problems of small window range, poor consistency, high resistance, poor consistency, etc., and achieve the effects of improving device performance, high resistivity, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: A memristor capable of shaping and positioning conductive filament channels and its preparation

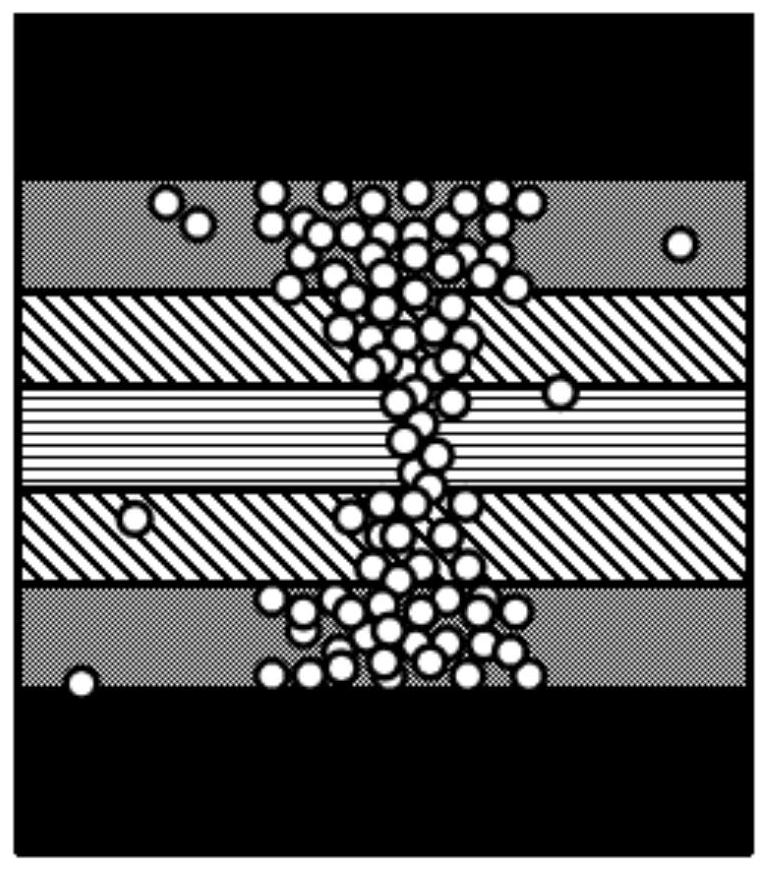

[0037] In the present invention, by using a homogeneous metal oxide layer, an oxygen vacancy conductive filament path similar to an "hourglass" shape is realized, and under the control of an electric field and Joule heat, the on-off position of the conductive filament is controlled in the middle of the functional layer (especially The middle of the functional layer), so as to realize the shaping and positioning of the conductive filament channel, which will be described in detail below in conjunction with the accompanying drawings.

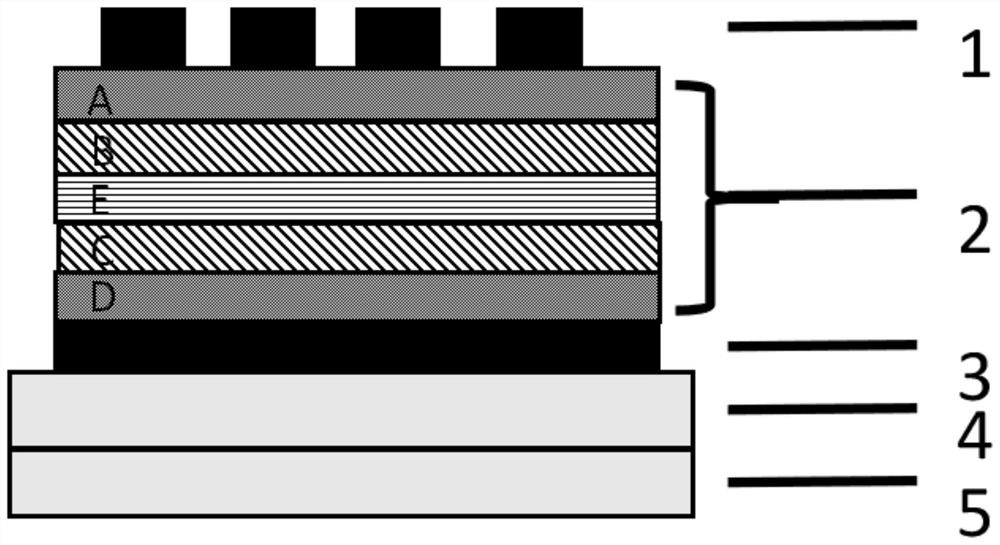

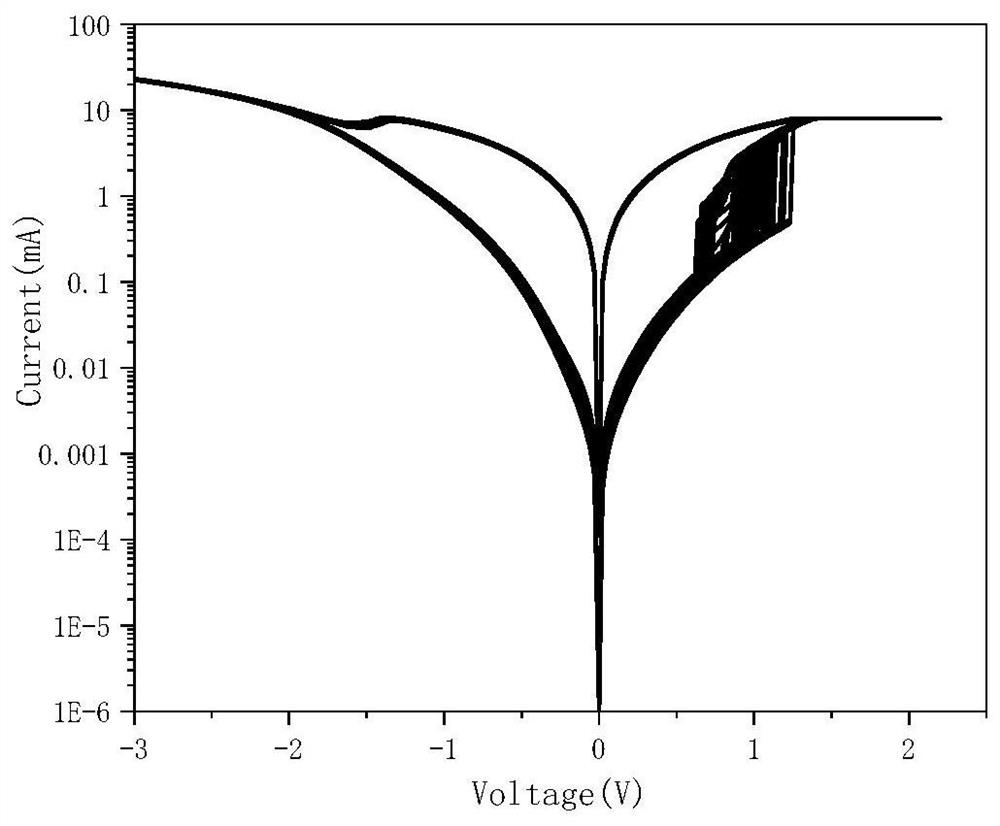

[0038] figure 1 Schematic diagram of the structure of the memristor that realizes the shaping and positioning of the conductive filament channel provided by the embodiment of the present invention. Specifically, the structure of the memristor device includes an electrode layer and a multilayer functional layer, and the functional lay...

Embodiment 2

[0054] Example 2: A memristor capable of shaping and positioning conductive filament channels and its preparation

[0055] In the present invention, by using a homogeneous metal oxide layer, an oxygen vacancy conductive filament path similar to an "hourglass" shape is realized, and under the control of an electric field and Joule heat, the on-off position of the conductive filament is controlled in the middle of the functional layer (especially The middle of the functional layer), so as to realize the shaping and positioning of the conductive filament channel, which will be described in detail below in conjunction with the accompanying drawings.

[0056] figure 1 Schematic diagram of the structure of the memristor that realizes the shaping and positioning of the conductive filament channel provided by the embodiment of the present invention. Specifically, the structure of the memristor device includes an electrode layer and a multilayer functional layer, and the functional lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com