Hybrid Excitation Turbo Generator with Multi-stage Axial-Centrifugal Ventilation and Cooling System

A turbo-generator, ventilation and cooling technology, applied in cooling/ventilation devices, magnetic circuits characterized by magnetic materials, magnetic circuits, etc., can solve the problem of increasing the cooling gas flow and pressure in the turbo-generator, reducing The volume of the turbo-generator, the temperature of the rotor excitation winding and the end member are high, so as to achieve the effect of increasing the flow rate and pressure, enhancing the strength of the air gap magnetic field, and increasing the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

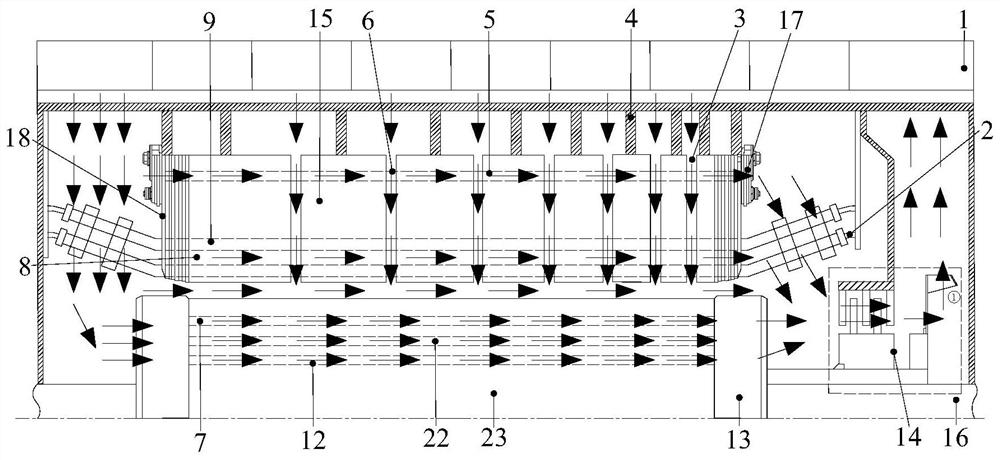

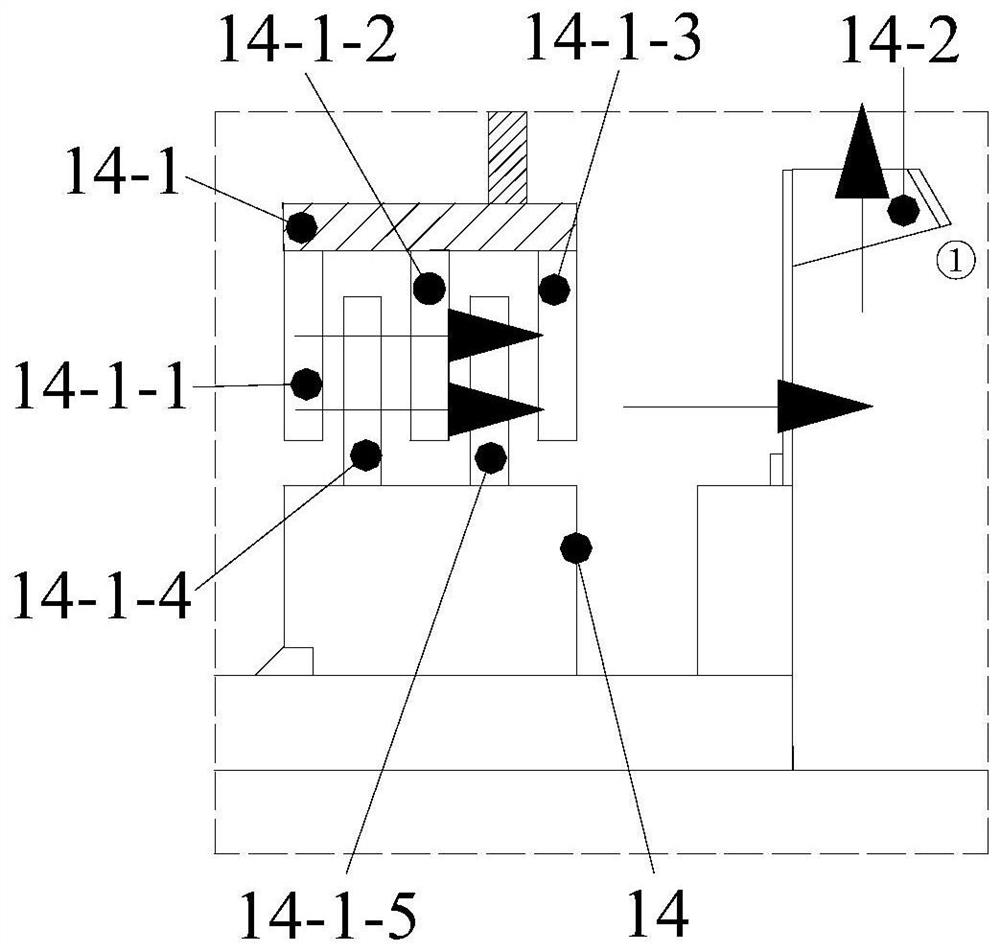

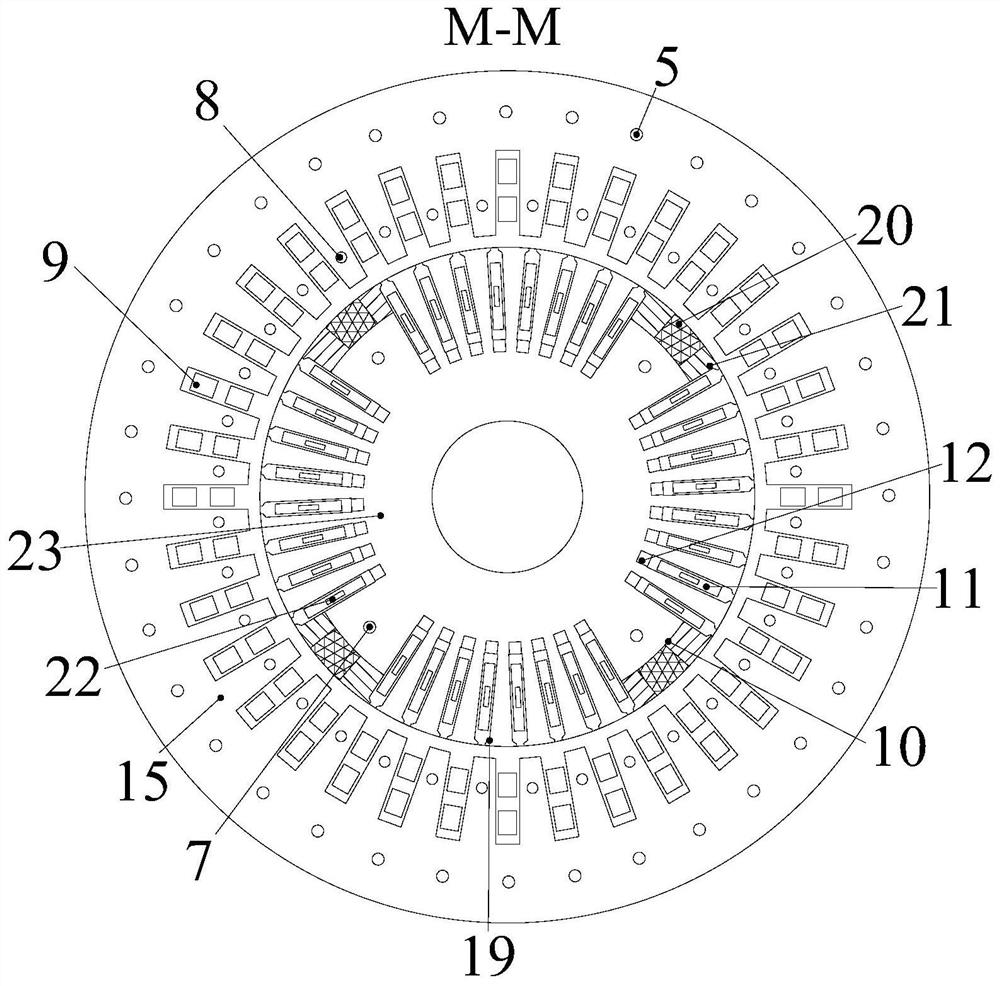

[0020] Embodiment 1: Combining figure 1 , figure 2 , image 3Illustrating this embodiment, it includes a cooler 1, a water pipe 2, a radial ventilation channel 3, a stator bracket 4, a stator yoke axial ventilation hole 5, an air guide ring 6, a rotor core axial ventilation hole 7, and a stator tooth portion. Axial ventilation hole 8, stator winding 9, sector groove 10, rotor excitation winding 11, rotor slot bottom ventilation channel 12, rotor guard ring 13, multi-stage axial-centrifugal hybrid fan 14, stator core segment 15, rotating shaft 16. Magnetic shield 17, pressure finger 18, rectangular deep groove 19, high coercivity permanent magnet 20, low coercivity permanent magnet 21, rotor inner cooling air passage 22 and rotor iron core 23, multi-stage axial flow-centrifugal The hybrid multi-stage fan 14 is composed of a multi-stage axial fan 14-1 and a centrifugal fan 14-2; the multi-stage axial fan 14-1 is composed of a first-stage static fan 14-1-1, a second-stage The...

specific Embodiment approach 2

[0023] Specific implementation mode 2: Combining Figure 4 Describing this embodiment, the difference between this embodiment and the first embodiment is that the cross-sectional area of the axial ventilation hole 5 in the stator yoke portion gradually decreases along the direction of the cooling gas flow, so that the cooling gas velocity is along the direction of the cooling gas flow. Gradually increases, thereby reducing the influence of the cooling effect of the yoke of the stator core segment 15 becoming worse due to the increase in the temperature of the cooling gas, improving the utilization rate of the cooling gas, and further reducing the temperature of the yoke of the stator core segment 15 . Other components and connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation three: combination Figure 5 Describing this embodiment, the difference between this embodiment and the first embodiment is that the cross section of the axial ventilation holes 8 of the stator teeth is changed from a circle to a rectangle, which improves the surface heat dissipation coefficient of the stator core segment 15 and further reduces the The temperature of the teeth of the stator core segment 15 of equal thickness. Other components and connection relationships are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com