Hydrogen extraction device and process for recovering tail gas components from synthetic hydrogen

A technology of tail gas and gas-liquid separator, which is applied in the directions of gas treatment, separation method, and dispersed particle separation, etc., which can solve the problems of low utilization rate of resources, and achieve the effect of improving utilization rate, increasing yield, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

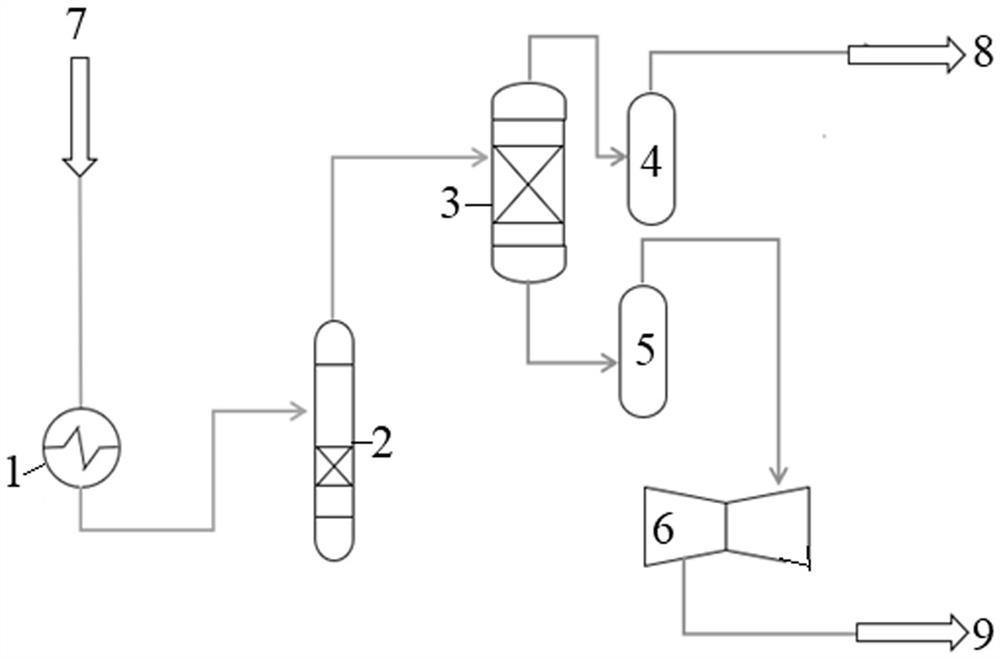

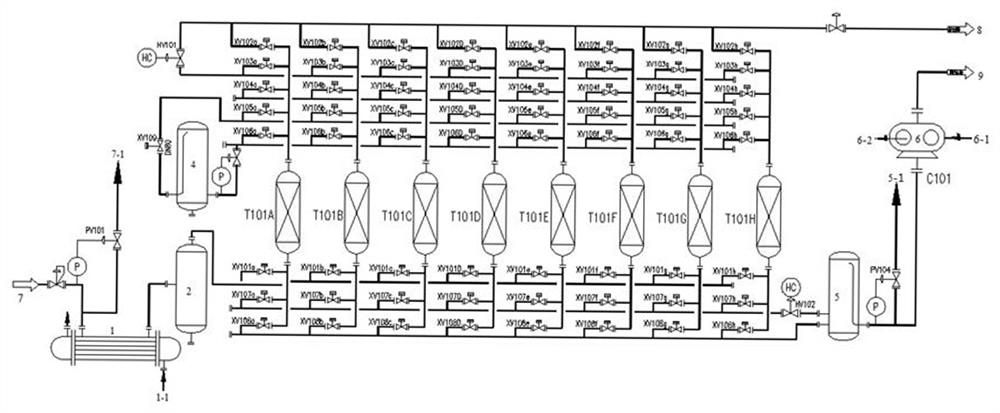

[0054] The present invention provides a device for synthesizing hydrogen to recover tail gas components, such as figure 1 As shown, it includes a cooler 1, a gas-liquid separator 2, an adsorption tower system 3, a degassing buffer tank 4, a desorbing gas buffer tank 5 and an analytical gas compressor 6, and the cooler 1 is connected to the gas-liquid through a pipeline. Separator 2, gas-liquid separator 2 is connected to adsorption tower system 3 through pipeline, and the upper end of adsorption tower system 3 is connected with degassing buffer tank 4 through pipeline, and the lower end of adsorption tower system 3 is connected with desorption gas buffer tank 5 through pipeline, desorption The suction buffer tank 5 is connected with an analytical gas compressor 6 . Wherein the adsorption tower system 3 includes a total of eight identical adsorption towers of A tower, B tower, C tower, D tower, E tower, F tower, G tower and H tower, and the eight adsorption towers are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com