JS polymer cement-based waterproof coating stirring equipment

A technology for waterproof coating and mixing equipment, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve problems such as peeling, uneven mixing of paint, and easy adhesion of paint, etc., to increase the use form and mixing effect. Better, friction-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

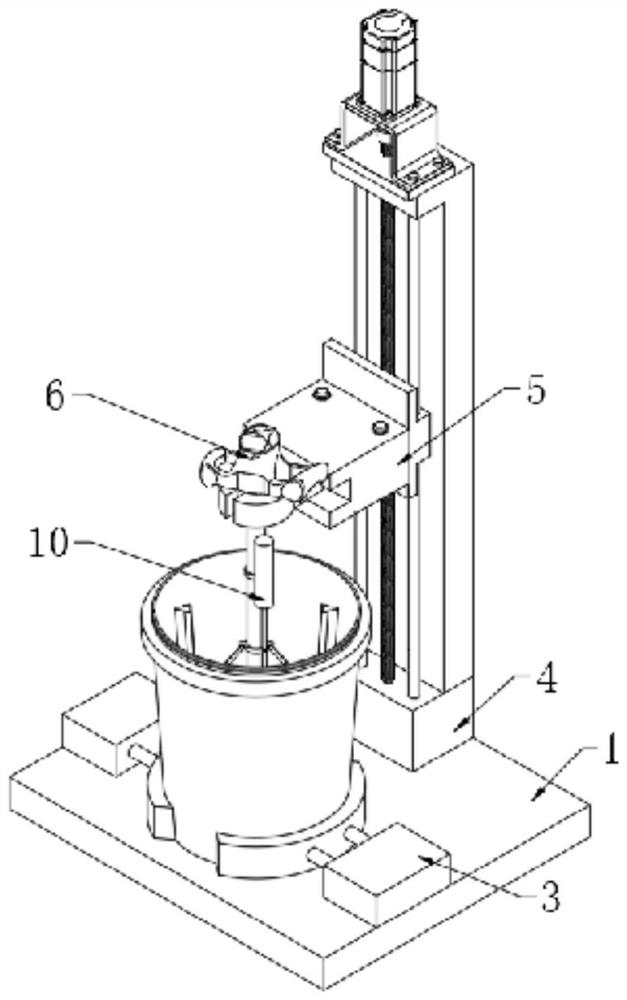

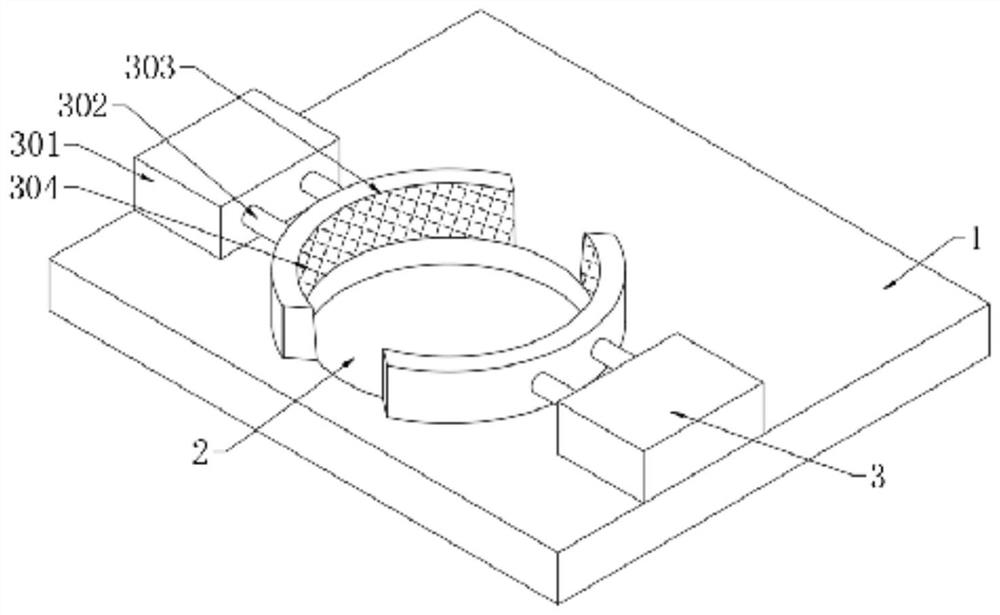

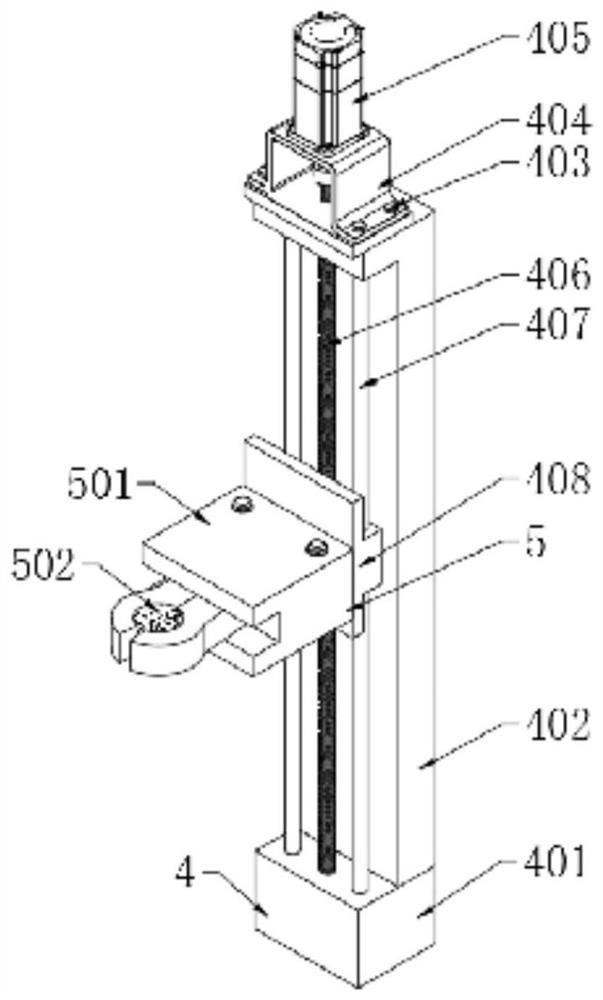

[0036] see Figure 1-7 , a JS polymer cement-based waterproof coating mixing equipment, consists of a storage board 1, a positioning mechanism 3, a moving component 4, a clamping mechanism 5, a transmission mechanism 6, a stirring blade 8, a limit head 9, and a scraper mechanism 11.

[0037] Wherein, the combination of the storage tank 2 and the positioning mechanism 3 can limit the position of the mixing tank, avoiding the mixing tank from moving arbitrarily when stirring, the upper surface of the storage board 1 is provided with a storage tank 2, and both sides of the storage tank 2 are provided with a positioning mechanism 3 , the lower surface of the positioning mechanism 3 is threadedly connected to the upper surface of the storage board 1 .

[0038] Wherein, the moving assembly 4 is fixedly connected to the upper surface of the storage board 1, and the front of the moving assembly 4 is movably connected with a clamping mechanism 5, and the moving assembly 4 is started to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com