Spraying robot demonstrator and method

A technology of spraying robot and teaching method, which is applied in the directions of manipulator, spraying device, program-controlled manipulator, etc., can solve the problems that the robot is difficult to obtain the spraying speed, the visual technology is greatly affected by the light source, and is easily blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

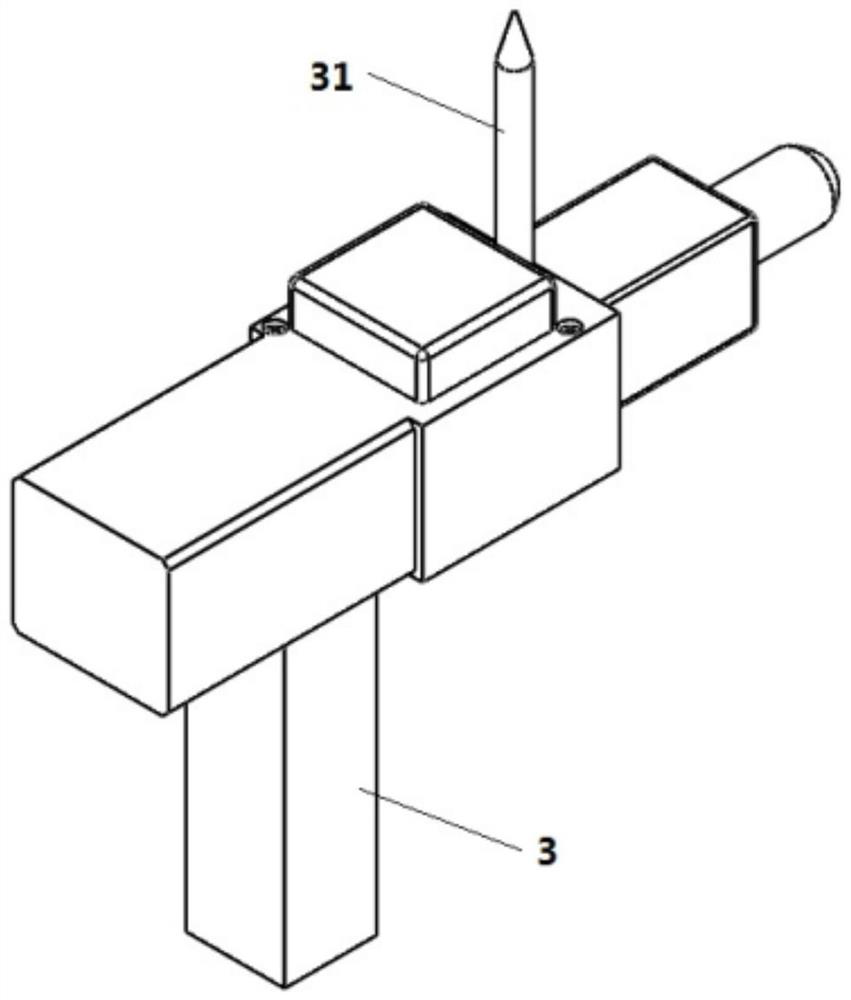

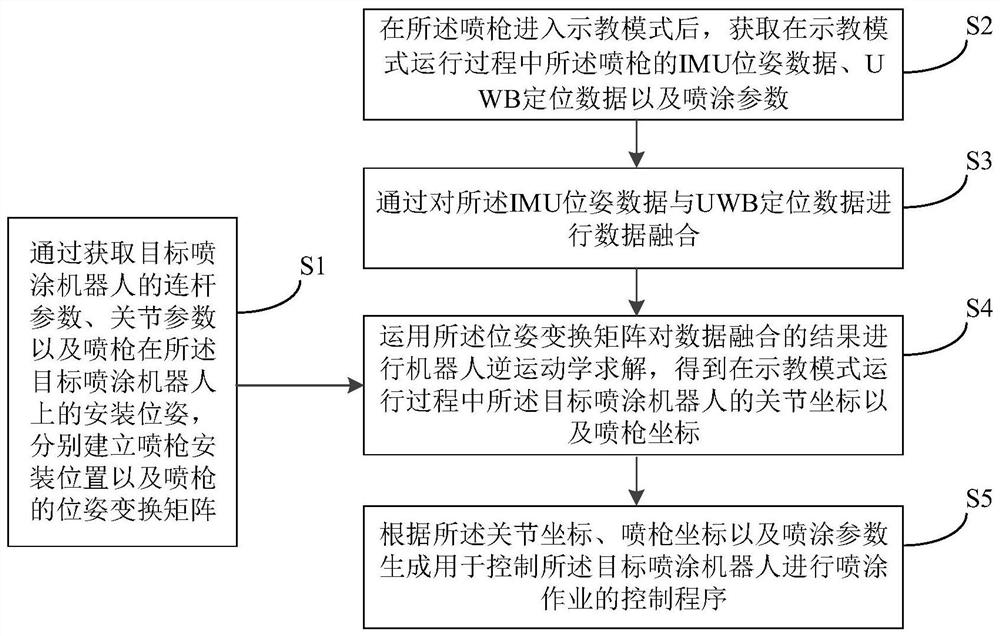

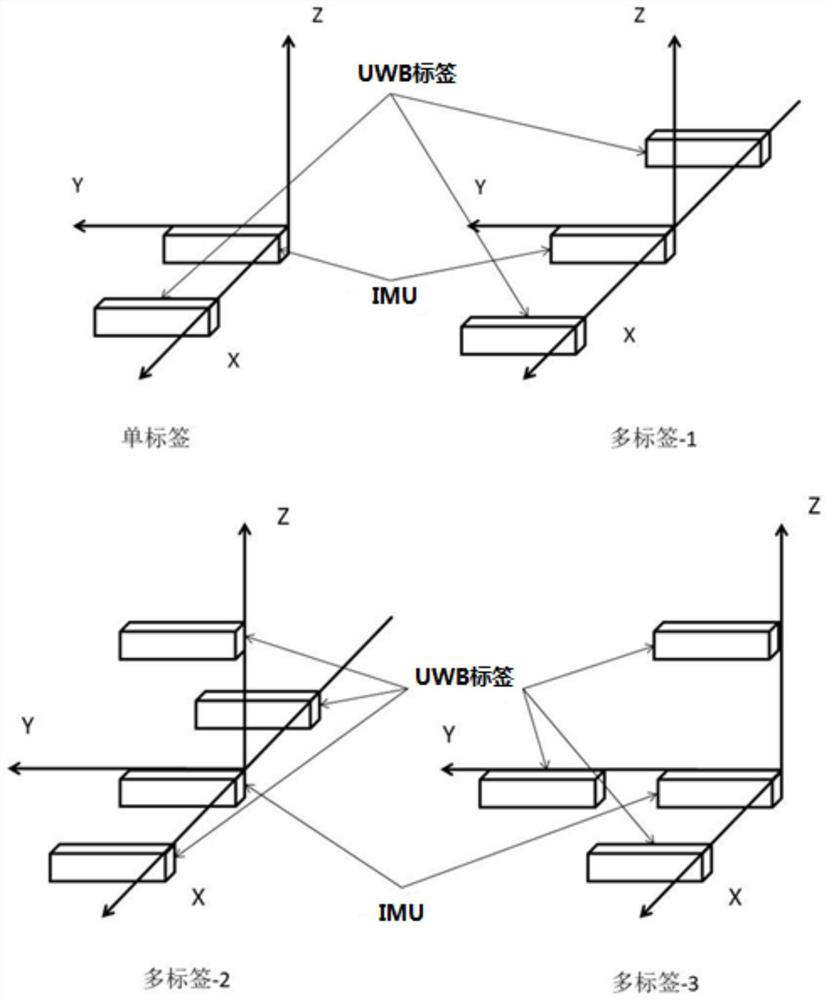

[0050] A spraying robot teaching device, please refer to figure 1 , including a spray gun 3 that can be installed on a spraying robot, the spray gun 3 is provided with an MCU, an IMU, and a UWB tag for three-dimensional positioning; the MCU is used to control the IMU and the UWB tag, and the IMU and the UWB tag The sampling data and the spraying parameters of the spray gun 3 are stored and transmitted.

[0051] As a preferred embodiment, the MCU keeps time synchronization between the IMU and the sampling data of the UWB tag and the spraying parameters of the spray gun 3 through a unified time stamp.

[0052] Specifically, the working modes of the teaching pendant of the painting robot include a teaching mode, in which the operator can hold the teaching pendant of the painting robot to perform manual teaching, that is, to perform a spraying operation on a workpiece.

[0053] The MCU, IMU and UWB tags can be integrated into a PCB board located on the spray gun 3, and the MCU co...

Embodiment 2

[0088] A spraying robot teaching system, please refer to Image 6 , comprising a pose transformation matrix acquisition module 10, a teaching data acquisition module 20, a data fusion module 30, a robot inverse kinematics solution module 40, and a control program generation module 50; the data fusion module 30 is connected to the teaching data acquisition module 20 and the robot inverse kinematics solution module 40, the robot inverse kinematics solution module 40 is connected to the pose transformation matrix acquisition module 10 and the control program generation module 50, and the control program generation module 50 is connected to the teaching data acquisition module Module 20; where:

[0089] The pose transformation matrix acquisition module 10 is used to establish the installation position of the spray gun and the pose transformation matrix of the spray gun by acquiring the connecting rod parameters, joint parameters and the installation pose of the spray gun on the ta...

Embodiment 3

[0095] A medium, on which a computer program is stored, and when the computer program is executed by a processor, the data processing steps of the teaching method for a painting robot in Embodiment 1 are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com