A double-sided laminating machine

A laminating machine, double-sided technology, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of easy wrinkling of the film, affecting the lamination effect, etc. Consistent effect of membrane steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

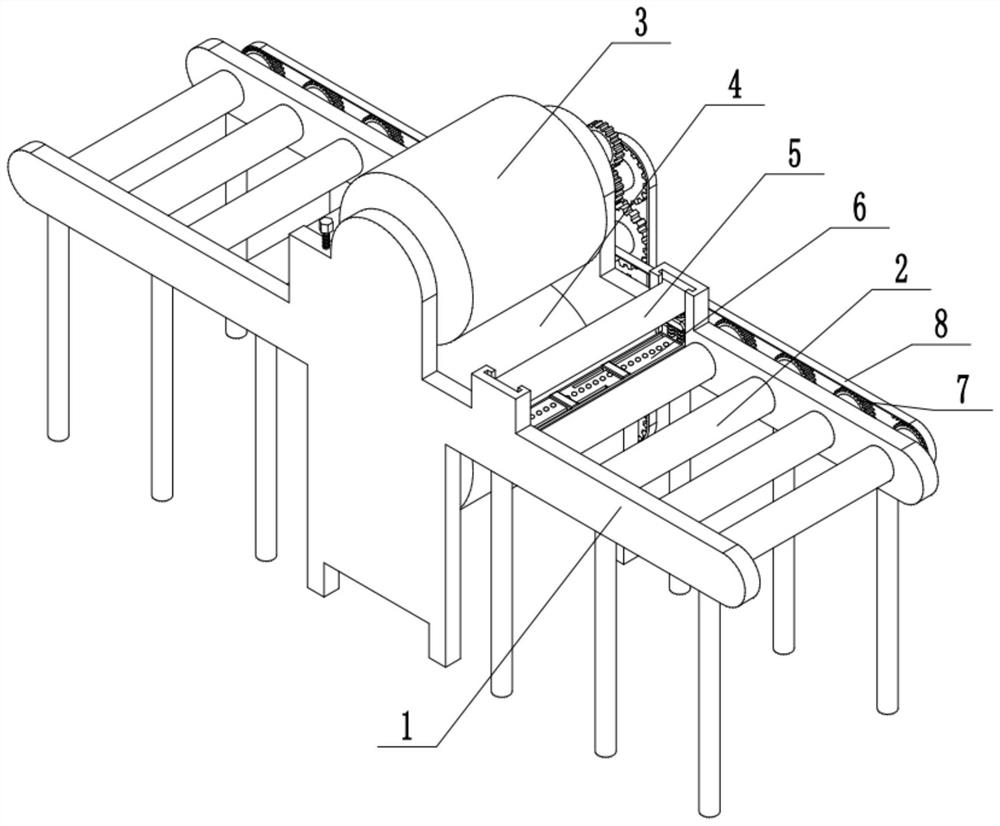

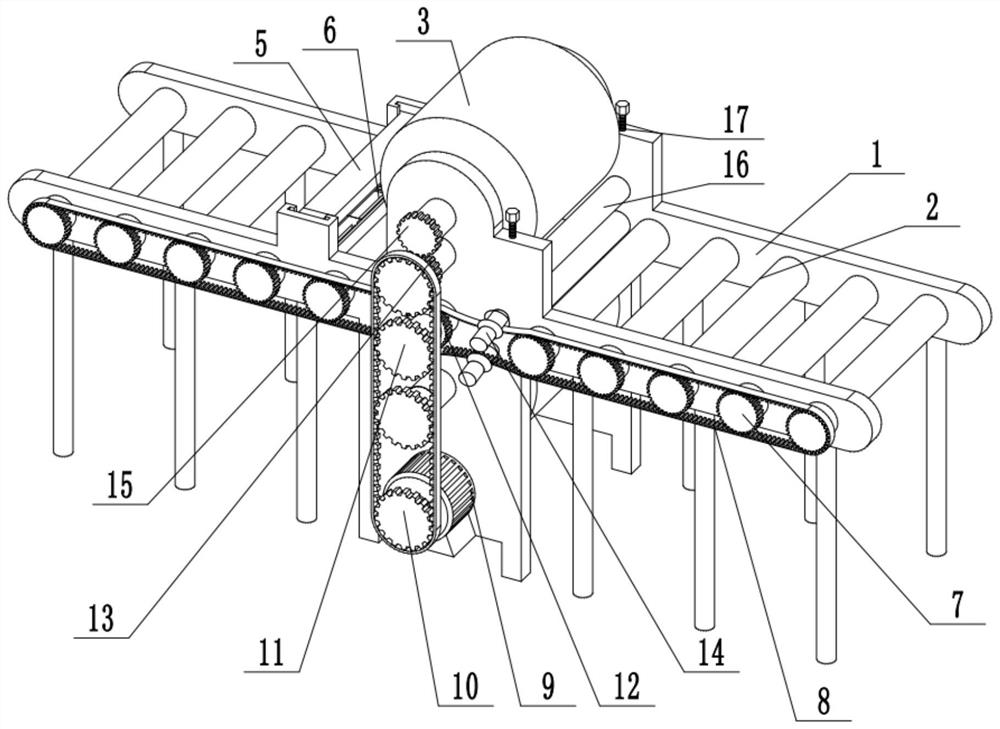

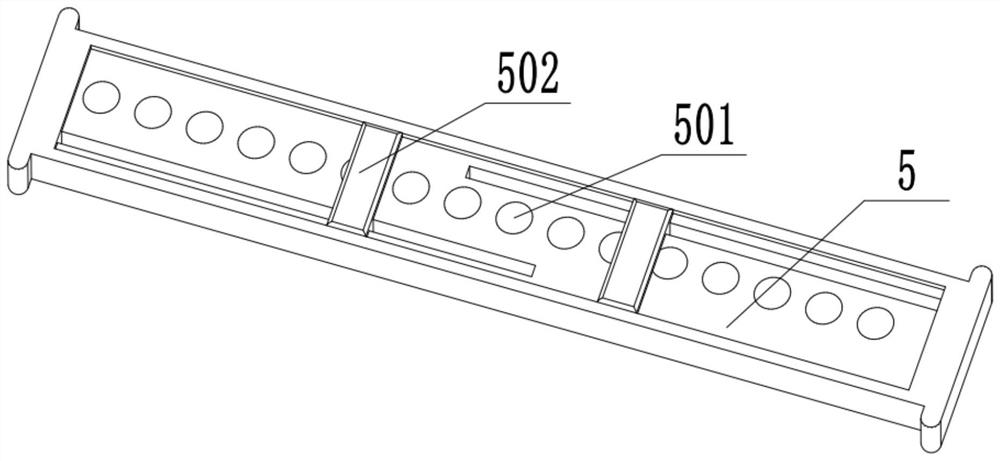

[0028] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0029] Reference numerals in the accompanying drawings include: support frame 1, transmission roller 2, upper film roller 3, lower film roller 4, upper guide block 5, air outlet 501, push plate 502, motor 503, transmission gear 504, first Rack 505, second rack 506, connecting rod 507, piston rod 508, air bag 509, air tube 510, lower guide block 6, second driven pulley 7, second timing belt 8, motor 9, driving pulley 10. The first driven pulley 11 , the conversion pulley 12 , the driving gear 13 , the tensioning pulley 14 , the driven gear 15 , the tensioning roller 16 , the fixed shaft 1601 , the tensioning sleeve 1602 , and the double-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com