SiC fiber reinforced and toughened (SiC-BN)m multi-element multilayer self-healing ceramic matrix composite material and preparation method thereof

A composite material and fiber reinforced technology, which is applied in the field of SiC fiber reinforced and toughened (SiC-BN)m multi-layer self-healing ceramic matrix composite materials and preparation, can solve the problems of unfavorable composite mechanical properties and improvement, and achieve The effect of synergistic improvement of mechanical properties and self-healing properties, increasing crack propagation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

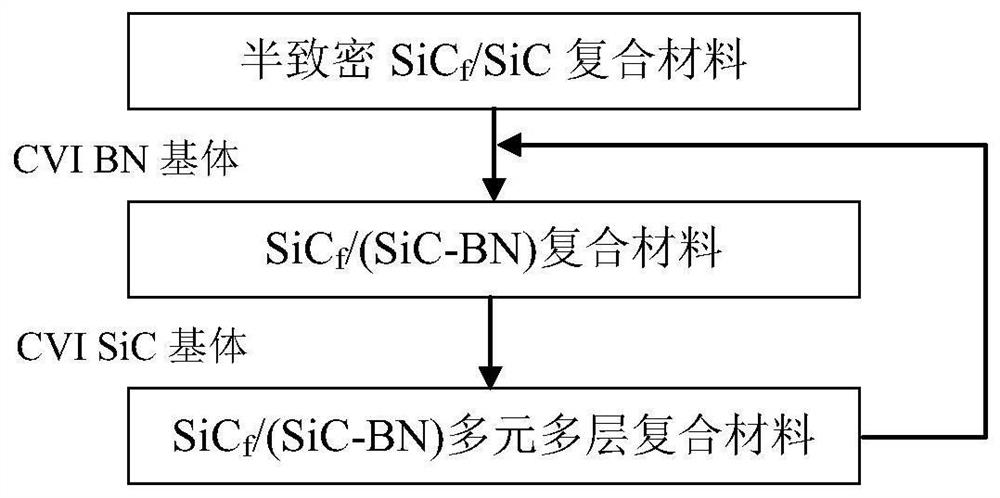

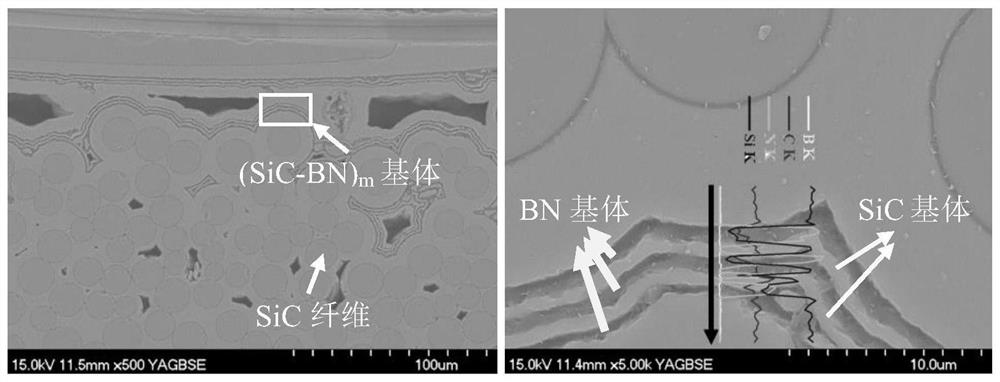

Method used

Image

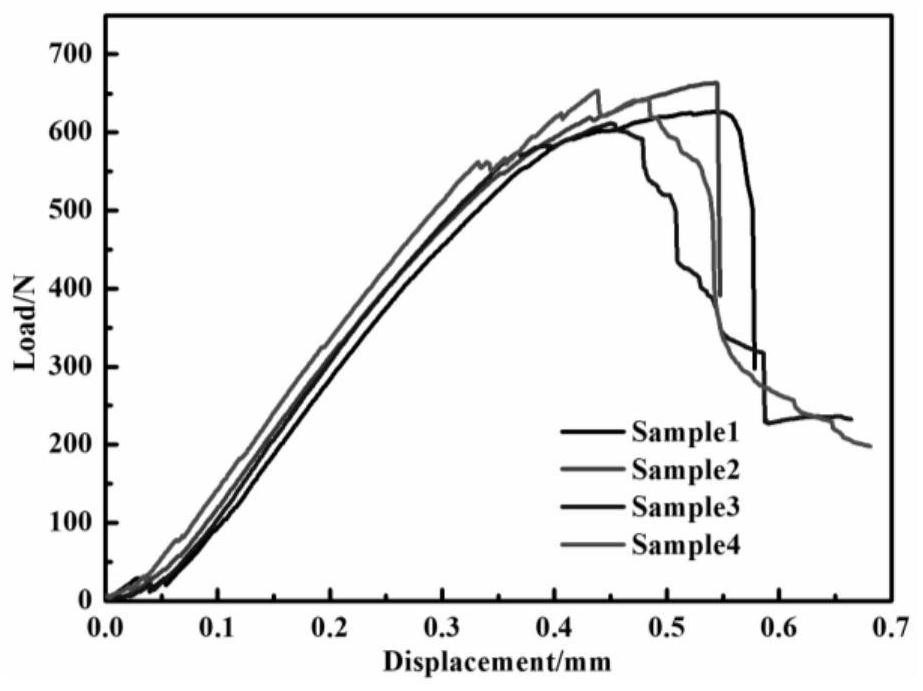

Examples

Embodiment 1

[0046] (1) Put 20 sheets of 16cm×16cm 2 Two-dimensional plain-weave SiC fibers (500 fibers / bundle) were laminated and fixed with graphite fixtures to obtain a two-dimensional SiC fiber preform.

[0047] (2) Hang the fiber prefabricated body on the supporting sample rack of the PyC deposition furnace, so that it is in the center of the isothermal zone in the furnace, and at the same time, pass through propylene (C 3 h 6 ), diluent gas argon (Ar), keep the pressure in the furnace at 2kPa, deposit the PyC interface at 850°C, and the deposition time is 40h, and obtain a SiC fiber preform sample with a thickness of 400nm PyC interface.

[0048] (3) Hang the SiC fiber preform deposited with the PyC interface on the supporting sample holder of the SiC deposition furnace, the preform is located in the center of the isothermal zone in the furnace, and the deposition time is 300h to obtain semi-dense SiC f / SiC composites.

[0049] (4) The semi-dense SiC f / SiC composite material is...

Embodiment 2

[0056] (1) Divide 16cm×16cm 2 2.5D SiC fiber preforms (500 pieces / bundle) were fixed with graphite fixtures to obtain two-dimensional and half SiC fiber preforms.

[0057] (2) Hang the fiber prefabricated body on the supporting sample rack of the PyC deposition furnace, so that it is in the center of the isothermal zone in the furnace, and at the same time, pass through propylene (C 3 h 6 ), diluting gas argon (Ar), keeping the pressure in the furnace at 2kPa, depositing the PyC interface at 870°C for 55h, and obtaining a SiC fiber preform sample with a thickness of 500nm PyC interface.

[0058] (3) Hang the SiC fiber preform deposited with the PyC interface on the supporting sample holder of the SiC deposition furnace, the preform is located in the center of the isothermal zone in the furnace, and the deposition time is 260 h to obtain semi-dense SiC f / SiC composites.

[0059] (4) The semi-dense SiC f / SiC composite material is suspended on the supporting sample rack of...

Embodiment 3

[0063] (1) A 16cm×16cm 3D SiC fiber preform (500 pieces / bundle) was fixed with a graphite fixture to obtain a three-dimensional SiC fiber preform.

[0064] (2) Hang the fiber prefabricated body on the supporting sample rack of the PyC deposition furnace, so that it is in the center of the isothermal zone in the furnace, and at the same time, pass through propylene (C 3 h 6 ), diluting gas argon (Ar), keeping the pressure in the furnace at 2kPa, depositing the PyC interface at 820°C for 30h, and obtaining a SiC fiber preform sample with a thickness of 300nm PyC interface.

[0065] (3) Hang the SiC fiber preform deposited with the PyC interface on the supporting sample holder of the SiC deposition furnace, the preform is located in the center of the isothermal zone in the furnace, and the deposition time is 320 h to obtain semi-dense SiC f / SiC composites.

[0066] (4) The semi-dense SiC f / SiC composite material is suspended on the supporting sample rack of the BN deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com