Natural gas dechlorination device and process

A natural gas and dechlorination technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve problems such as environmental pollution, increased investment in purification plants, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

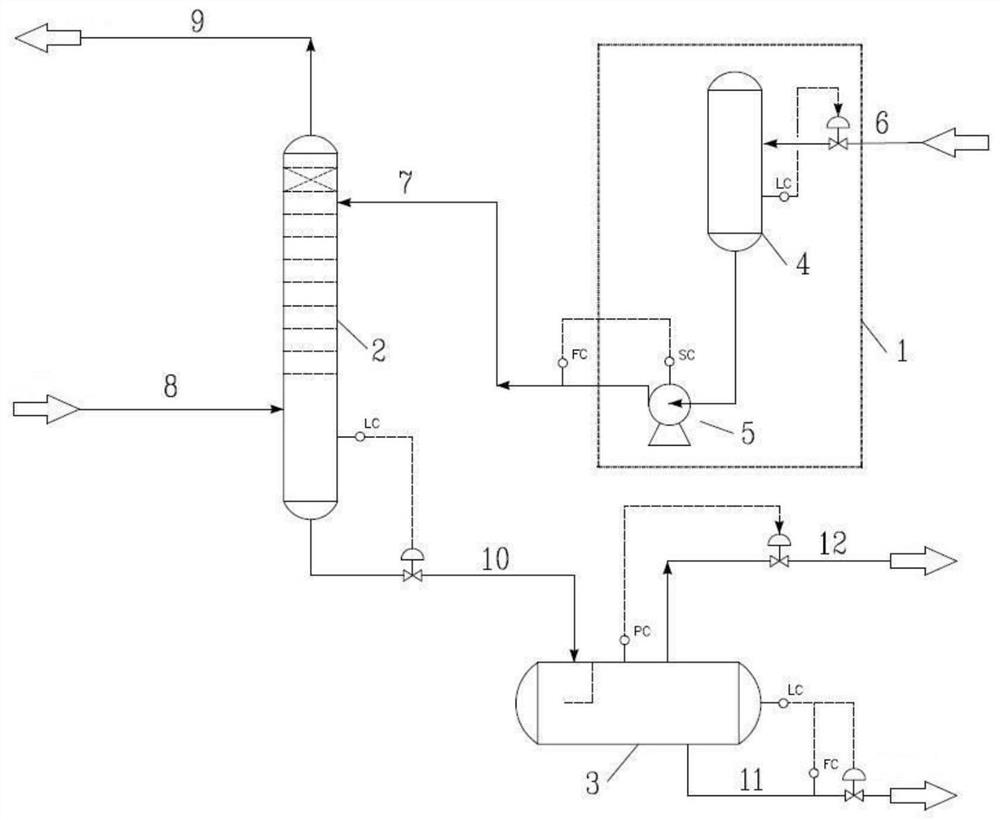

[0036] According to a specific embodiment of the present invention, the natural gas dechlorination process includes:

[0037] 1) The flushing water of the public works unit enters the flushing water buffer tank through the boundary flushing water pipeline, and the flushing water in the flushing water buffer tank is boosted by the flushing water pump, and then enters the natural gas dechlorination tower through the flushing water inlet;

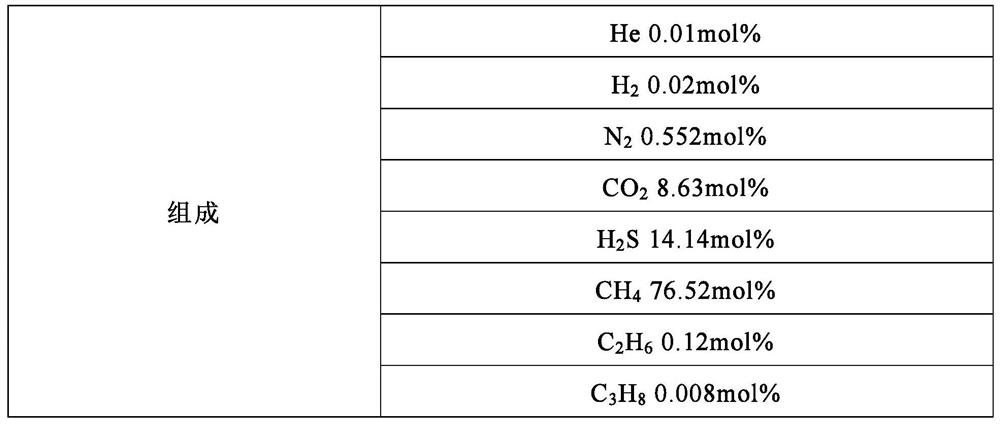

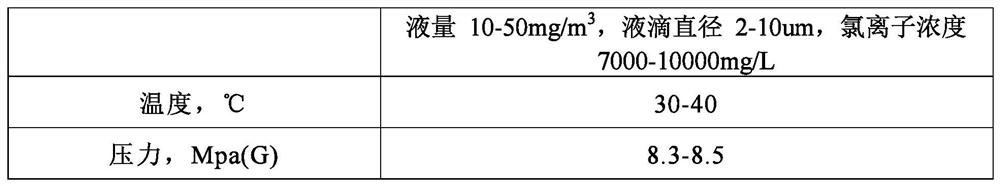

[0038] 2) Natural gas enters the natural gas dechlorination tower from the natural gas inlet, and the flushing water and natural gas are in reverse contact in the natural gas dechlorination tower to remove the chloride ions carried in the natural gas and dissolve a small amount of H at the same time 2 S, CO 2 and hydrocarbons, the dechlorinated natural gas enters the purification device through the dechlorinated natural gas outlet, and the chlorine-containing acidic water enters the acidic water flash tank through the chlorine-containing acidi...

Embodiment

[0046] This embodiment is used to illustrate the natural gas dechlorination device and process of the present invention.

[0047] Such as figure 1 As shown, the present invention provides a natural gas dechlorination device, which comprises flushing water buffer injection facility 1, natural gas dechlorination tower 2 and acid water flash tank 3;

[0048] The flushing water buffer injection facility 1 includes a flushing water buffer tank 4 and a flushing water pump 5, the water inlet of the flushing water buffer tank 4 is connected to the boundary flushing water pipeline, and the outlet of the flushing water buffer tank 4 passes through the flushing water pump 5 is connected with the flushing water inlet of natural gas dechlorination tower 2 top;

[0049] The lower part of the natural gas dechlorination tower 2 is provided with a natural gas inlet, the top is provided with a dechlorinated natural gas outlet, and the bottom is provided with an outlet for chlorine-containing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com