A kind of preparation method of titanium alloy material

A technology of titanium alloy and bulk material is applied in the field of preparation of titanium alloy material, achieving the effect of strong market application, simple and easy preparation process and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

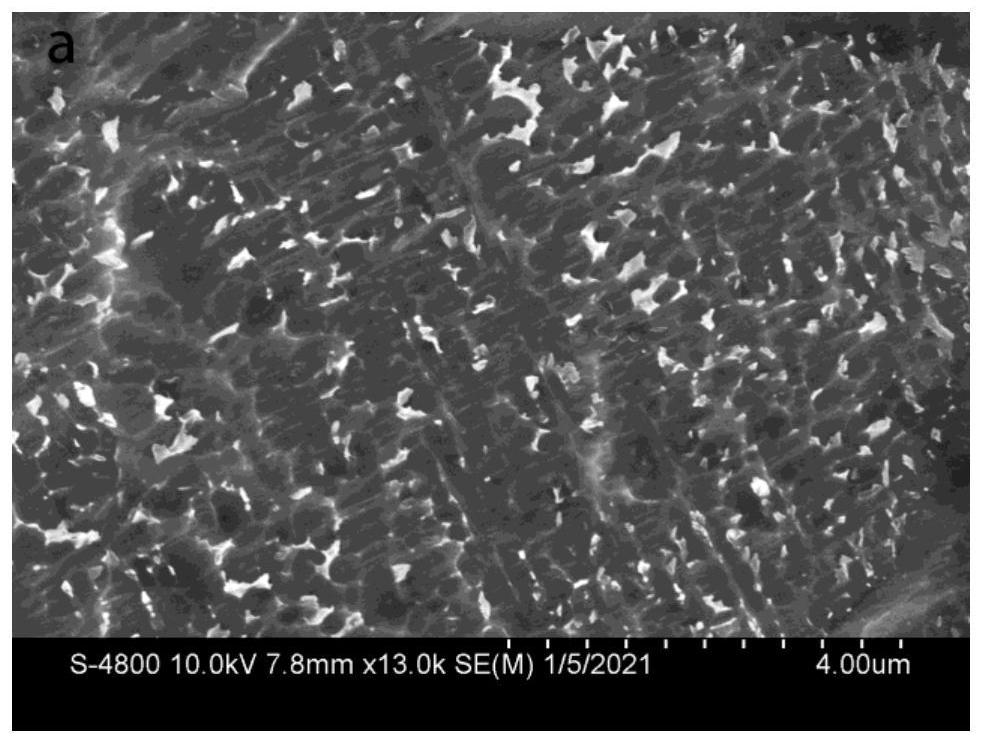

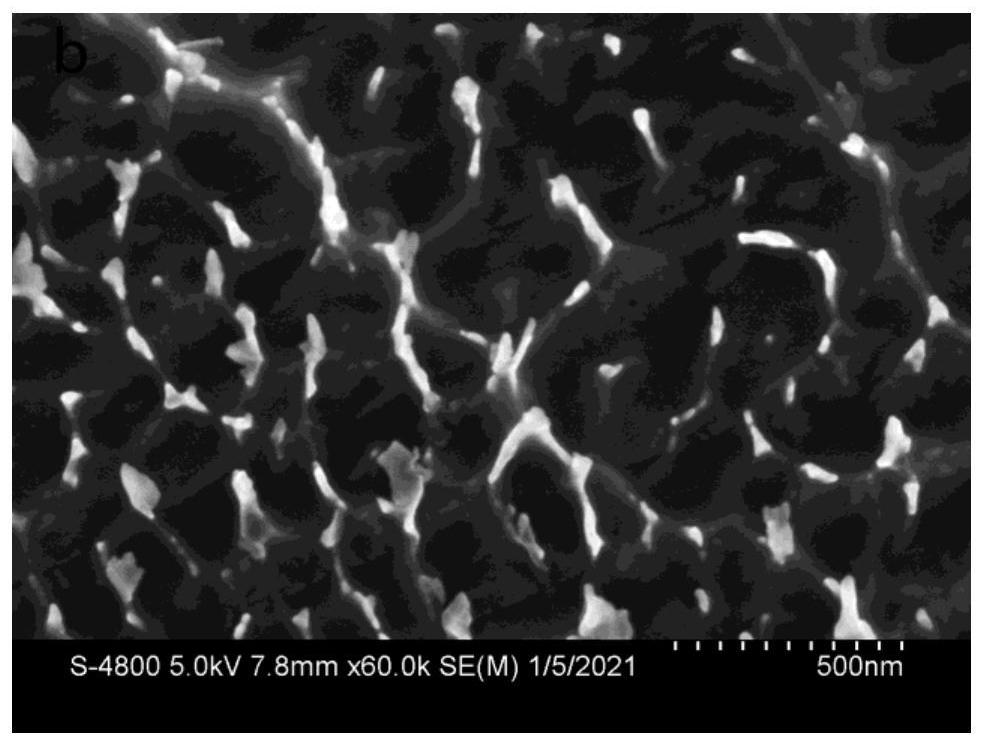

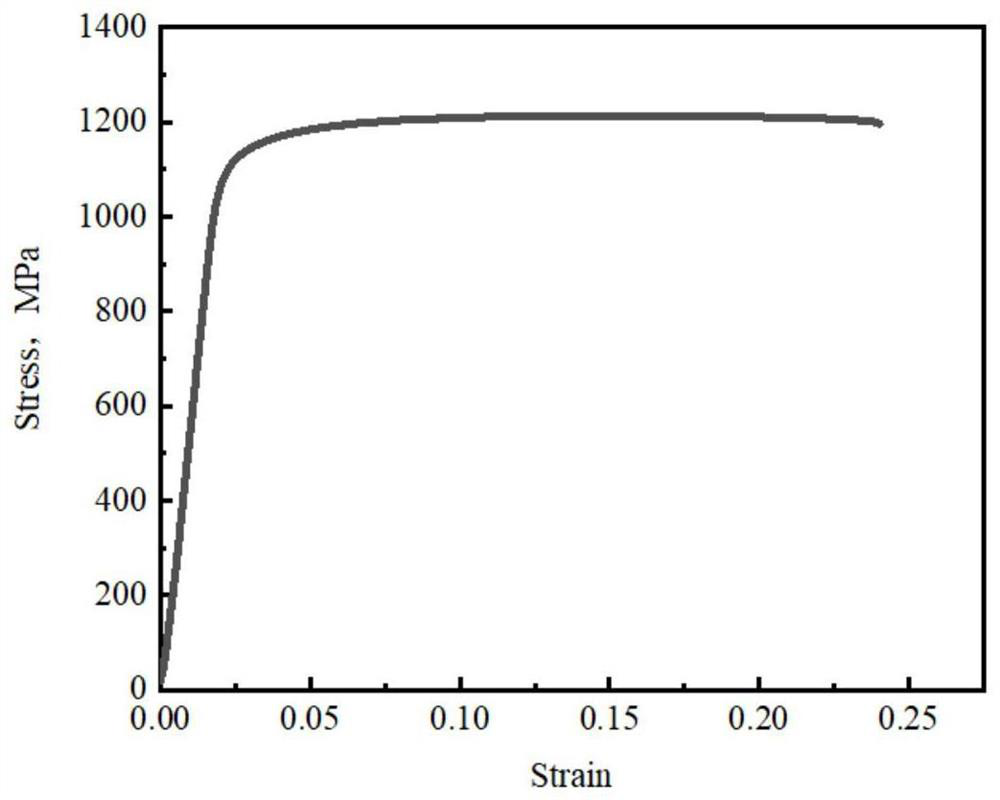

Image

Examples

Embodiment 1

[0038] (1) Put 14.14g of Ti-6Al-4V titanium alloy powder into a cemented carbide mold with an inner diameter of 20mm, and place it in a spark plasma sintering system for preform sintering. After sintering, clean the sintered with deionized water The material was dried naturally to obtain a block material with a height of 10mm and a diameter of 20mm.

[0039] The parameters of the preform sintering are: heating up to 600°C at a heating rate of 100°C / min for sintering, sintering pressure at 300MPa, heat preservation and pressure holding for 3 minutes, and after heat preservation and pressure holding, cool to 200°C with the furnace to take out the material.

[0040] The obtained block material was polished with 500-grit sandpaper until metallic luster appeared on the surface of the block material, the actual density was measured, and the density of the block material was calculated to be 95.4%.

[0041] (2) Put the block material with a height of 10mm and a diameter of 20mm into ...

Embodiment 2

[0047] (1) Put 22.10g of Ti-6Al-4V titanium alloy powder into a cemented carbide mold with an inner diameter of 25mm, and place it in a spark plasma sintering system for preform sintering. The material was dried naturally to obtain a block material with a height of 10mm and a diameter of 25mm.

[0048] The parameters of the preform sintering are: heating up to 650°C at a heating rate of 100°C / min for sintering, sintering pressure at 300MPa, heat preservation and pressure holding for 5 minutes, and after heat preservation and pressure holding, cool to 200°C with the furnace to take out the material.

[0049] The obtained block material was polished with 500-grit sandpaper until metallic luster appeared on the surface of the block material, its actual density was measured, and the density of the block material was calculated to be 96%.

[0050] (2) Put the block material with a height of 10mm and a diameter of 25mm into the middle of a carbon fiber mold with an inner diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com