Pearl traditional Chinese medicine anti-mosquito regenerated cellulose fiber and preparation method thereof

A technology of regenerated cellulose and pearls, applied in the direction of artificial filament made of viscose, which can solve the problems of high production cost and poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

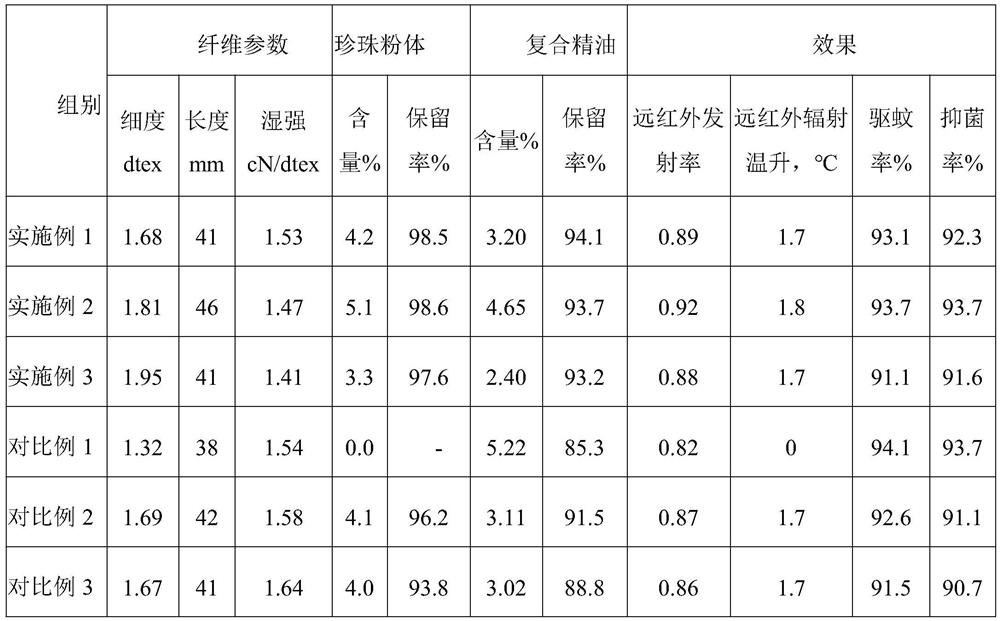

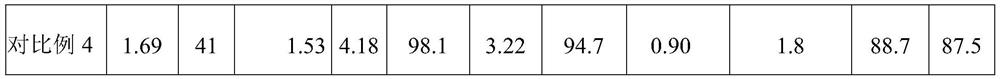

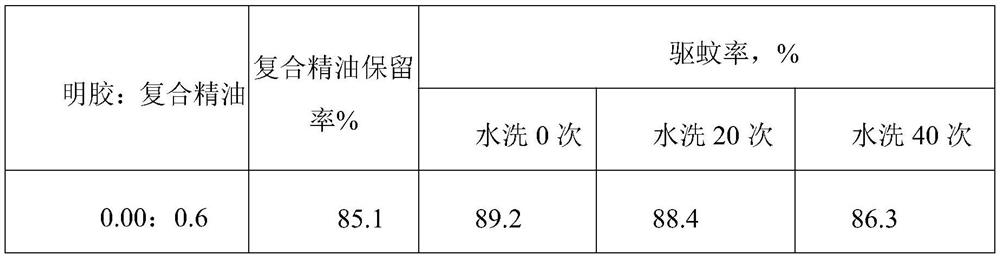

Examples

Embodiment 1

[0032] A method for preparing regenerated cellulose fibers of anti-mosquito pearl traditional Chinese medicine, the steps are: preparing pearl compound essential oil microcapsules—preparing blended spinning solution—spinning—post-treatment.

[0033] Among them, the preparation of pearl composite essential oil microcapsules includes: pretreatment of pearl powder - preparation of pearl powder and composite essential oil blend core material emulsion - coating of single-layer microcapsules - secondary coating.

[0034] Wherein, the pretreatment steps of pearl powder are:

[0035] Add the pearl powder to the surfactant solution, stir for 15 minutes to form a paste, and vacuum-dry; put the mixture in the reactor, stir (speed 1000r / m) and raise the temperature to 60°C, keep it warm for 5 minutes, and then raise the temperature to 90°C ℃, heat preservation for 9 minutes; after cooling to room temperature, ultrafine pulverization, so that the average particle size of the treated pearl ...

Embodiment 2

[0044] A method for preparing regenerated cellulose fibers of anti-mosquito pearl traditional Chinese medicine, the steps are: preparing pearl compound essential oil microcapsules—preparing blended spinning solution—spinning—post-treatment.

[0045] Among them, the preparation of pearl composite essential oil microcapsules includes: pretreatment of pearl powder - preparation of pearl powder and composite essential oil blend core material emulsion - coating of single-layer microcapsules - secondary coating.

[0046] Wherein, the pretreatment steps of pearl powder are:

[0047] Add the pearl powder to the surfactant solution, stir for 30 minutes to form a paste, and vacuum-dry; put the mixture in the reactor, stir (rotating speed 800r / m) and raise the temperature to 70°C, keep it warm for 3 minutes, and then raise the temperature to 95°C ℃, heat preservation for 5 minutes; after cooling to room temperature, ultrafine pulverization, so that the average particle size of the treate...

Embodiment 3

[0056] A method for preparing regenerated cellulose fibers of anti-mosquito pearl traditional Chinese medicine, the steps are: preparing pearl compound essential oil microcapsules—preparing blended spinning solution—spinning—post-treatment.

[0057] Among them, the preparation of pearl composite essential oil microcapsules includes: pretreatment of pearl powder - preparation of pearl powder and composite essential oil blend core material emulsion - coating of single-layer microcapsules - secondary coating.

[0058] Wherein, the pretreatment steps of pearl powder are:

[0059] Add the pearl powder to the surfactant solution, stir for 20 minutes to form a paste, and vacuum-dry; put the mixture in the reactor, stir (rotating speed 700r / m) and raise the temperature to 50°C, keep it warm for 10 minutes, and then raise the temperature to 80°C ℃, heat preservation for 10 minutes; after cooling to room temperature, ultrafine pulverization, so that the average particle size of the trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com