Anti-sticking device for electromechanical actuator and sticking fault judgment method

An electromechanical actuator and anti-jamming technology, which is applied to electromechanical devices, transmission control, electric components, etc. Eliminate problems such as hydraulic links to avoid stalling, improve practicability, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

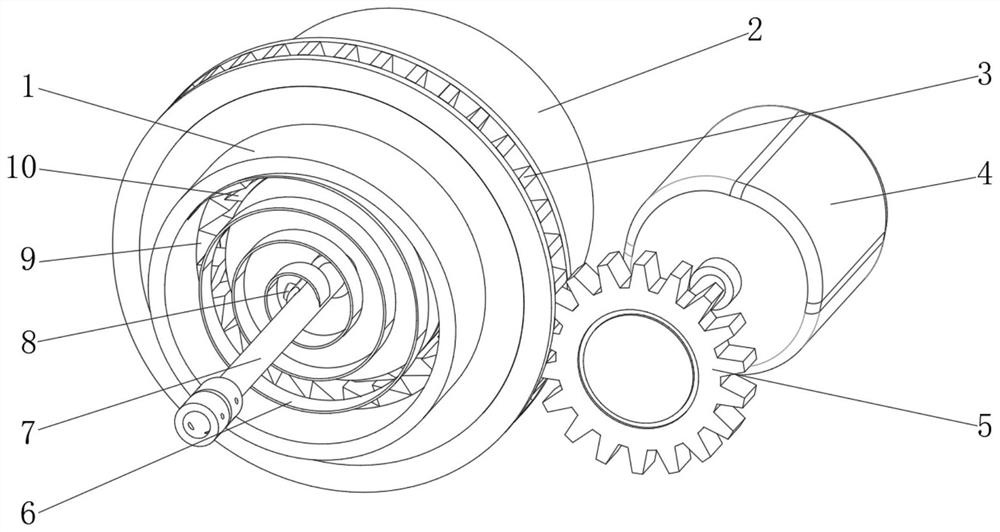

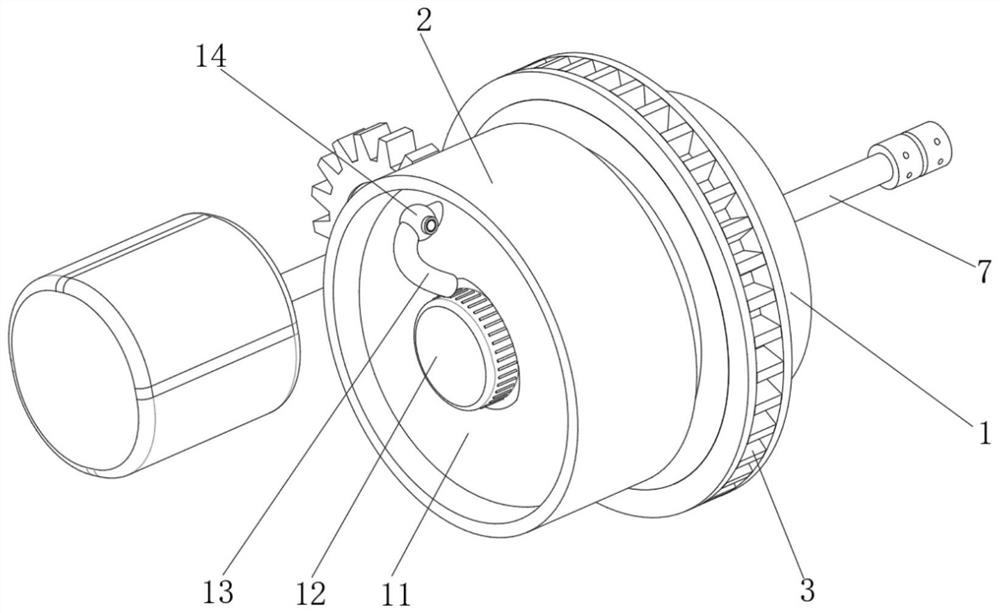

[0043] An anti-seize device for an electromechanical actuator, such as Figure 1-4 As shown, it includes a housing 1, a driven gear 3, a driving gear 5 and a driven shaft 7, the driven gear 3 is integrally arranged on the outer wall of the housing 1, the driven gear 3 is meshed with the driving motor 4, and the housing One side of the body 1 is provided with a drive motor 4 that drives the drive gear 5 to rotate, and the drive gear 5 is rotatably connected to the output end of the drive motor 4. The inner side of the housing 1 is provided with a linkage part 10, and the outer wall of the driven shaft 7 is Two mounting discs 19 are welded, the linkage part 10 includes a ratchet 18 and a ratchet spring 23, the ratchet 18 is installed between the two mounting discs 19 through a connecting shaft 24, and the ratchet 18 is rotatably connected to the outer wall of the connecting shaft 24, so The inner wall of the casing 1 is integrally provided with evenly distributed inner teeth 9, ...

Embodiment 2

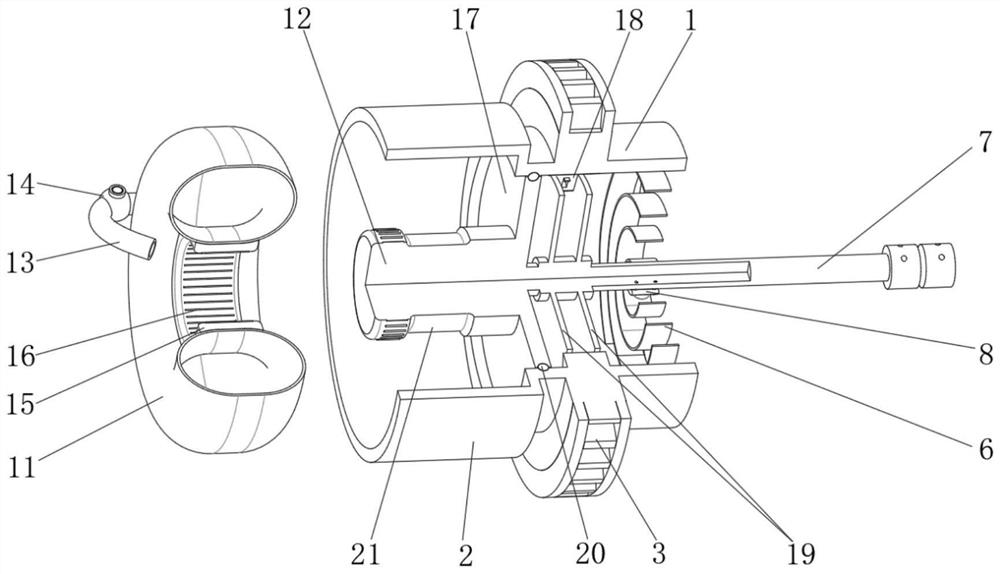

[0050] An anti-seize device for an electromechanical actuator, such as Figure 5-7 As shown, in order to improve the detection speed; this embodiment makes the following improvements on the basis of Embodiment 1: the planar scroll spring 6 is replaced by a shrapnel 25, and the two ends of the shrapnel 25 are respectively fixed on the inner wall of the housing 1 and from the On the outer peripheral wall of the driven shaft 7, each shrapnel 25 constitutes a tornado-like structure, and the pressure sensor 8 is installed on the outer peripheral wall of the driven shaft 7 through a fixed bracket 26; , through the rapid deformation of the shrapnel 25 to contact the pressure sensor 8, so that the pressure sensor 8 can sense the stuck phenomenon faster, which is beneficial to control the drive motor 4 to stop working in time, and improves the reliability.

[0051] In order to improve reliability, such as Figure 6 , Figure 7 As shown, the first annular airbag 11 is replaced with a ...

Embodiment 3

[0053] An anti-seize device for an electromechanical actuator, such as Figure 8 As shown, in order to simplify the structure; this embodiment makes the following improvements on the basis of Embodiment 1: the second annular air bag 27 is replaced by an elastic bag 31, and the elastic bag 31 is bonded to the circumferential inner wall of the annular seat 2, The inner wall of the elastic bag 31 is integrally provided with evenly distributed second arc-shaped protrusions 32, the second arc-shaped protrusions 32 are adapted to the arc-shaped grooves 29, and the second arc-shaped protrusions 32 are provided with Evenly distributed air holes 30; by setting the elastic bag 31 and the second arc-shaped protrusion 32, the elastic force of the elastic bag 31 can be used to maintain the firmness of contact with the friction column 12. When the driven shaft 7 is stuck, the second arc The shape protrusion 32 deforms and breaks away from the arc-shaped groove 29, so that airflow is generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com