A solid feed powder air blowing drying equipment

A drying equipment and air-blown technology, which is used in drying solid materials, heating to dry solid materials, feed, etc., can solve the problems of high water content of solid feed powder, prone to agglomeration, affecting feed quality, etc. Drying effect and efficiency, damage prevention, effect of efficient drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

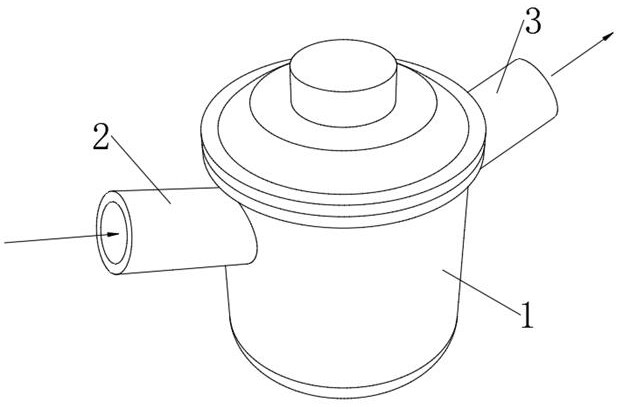

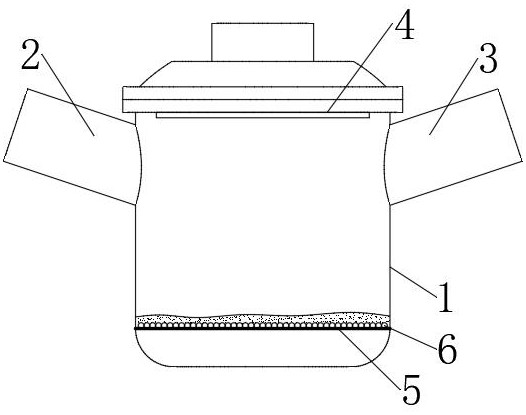

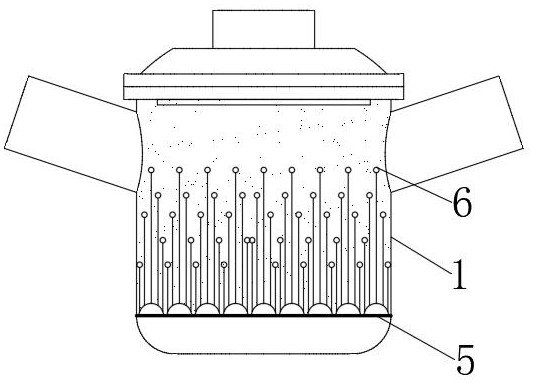

[0043] see Figure 1-3 , a solid feed powder air-blown drying equipment, including a drying furnace 1 and a control system, the left and right ends of the drying furnace 1 are respectively installed with an air inlet pipe 2 and an air outlet pipe 3, and the air inlet pipe 2 and the air outlet pipe 3 are in the same direction It is inclined downward to avoid the phenomenon that a small amount of solid feed powder is blown out. An electromagnet 4 is installed on the top of the drying furnace 1, and the electromagnet 4 is electrically connected to the control system. A powder throwing layer 5 is installed on the bottom of the drying furnace 1. A plurality of evenly distributed drying balls 6 are arranged on the upper side of the powder layer 5 , and distribution pull wires 7 are fixedly connected between the drying balls 6 and the powder throwing layer 5 .

[0044] The lengths of the correspondingly connected distribution stay wires 7 on the dispersing unit are different. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com