Hydrogen concentration monitoring device, system and method

A concentration monitoring and hydrogen technology, applied in measurement devices, sampling devices, thermal conductivity of materials, etc., can solve the problems of requiring a long time, long response time to start, difficult to adapt to hydrogen concentration detection, etc., and achieve the effect of improving the response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

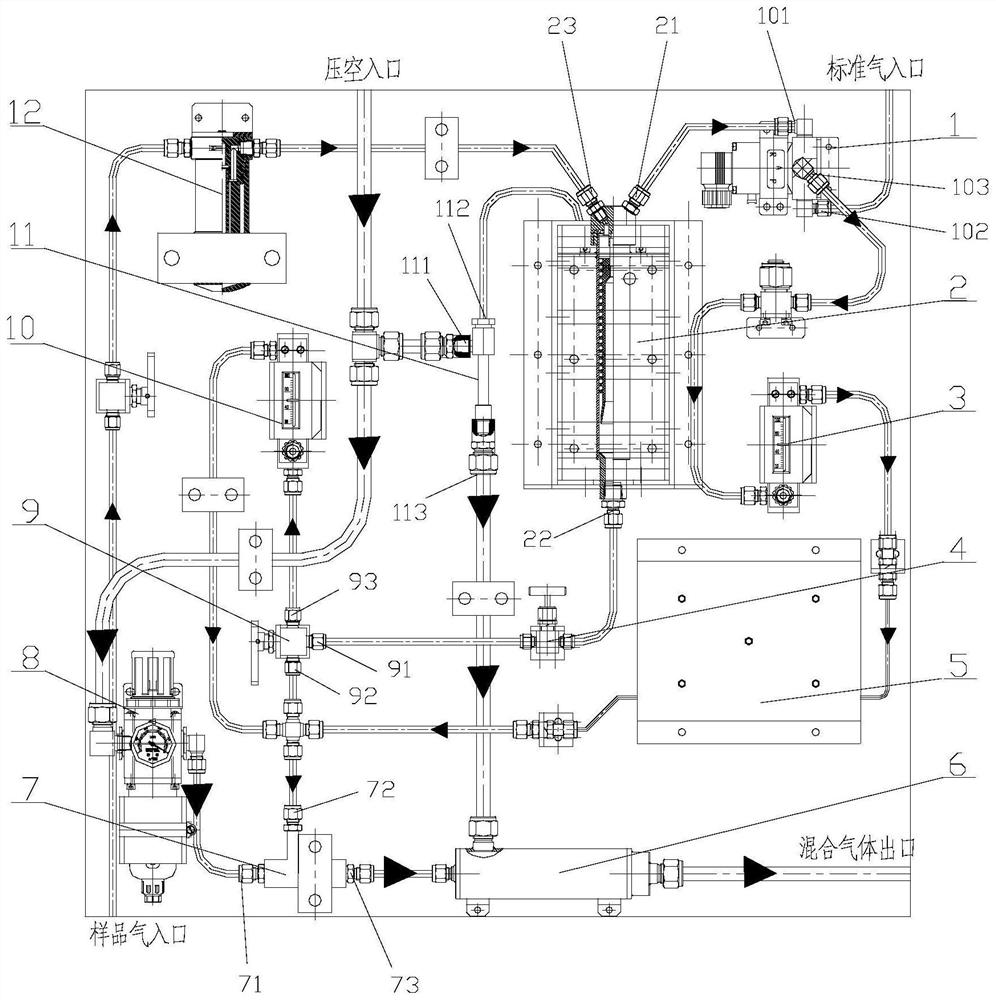

[0054] Such as figure 1 As shown, the hydrogen concentration monitoring device of this embodiment includes: a negative pressure suction assembly, a vortex condenser and a thermal conductivity sensor 5;

[0055] The vortex condenser has a first sample gas outlet 21 and a second sample gas outlet 22, the first sample gas outlet 21 is connected to the inlet of the thermal conductivity sensor 5,

[0056] The negative pressure suction assembly includes a compressed air injector 7, which is connected to the second sample gas outlet 22, and is used to generate a low pressure to draw the sample gas in the sample gas source into the vortex condenser, and the compressed air injector 7 is also connected with the outlet of thermal conductivity sensor 5,

[0057] The vortex condenser is used to condense the sample gas entering the vortex condenser to remove the water vapor in the sample gas,

[0058] Part of the condensed sample gas enters the compressed air injector 7 through the second...

Embodiment 2

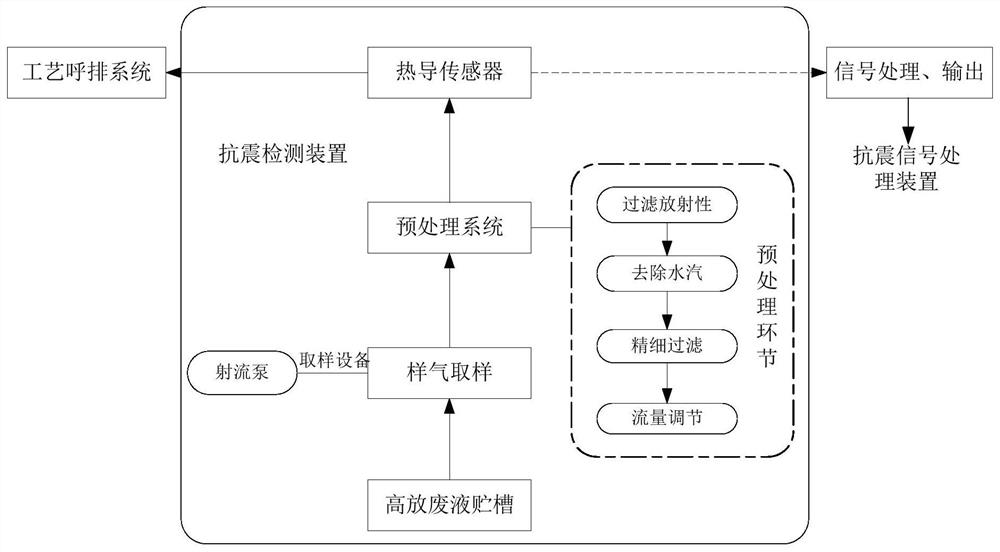

[0107] Such as figure 2 As shown, the present embodiment provides a hydrogen concentration monitoring system, including a signal processing device and the hydrogen concentration monitoring device of Embodiment 1, and the signal processing device is electrically connected to the thermal conductivity sensor 5 of the hydrogen concentration monitoring device for collecting heat The hydrogen concentration detection electrical signal output by the conductive sensor 5 is converted and processed to output the concentration value of hydrogen in the sample gas.

[0108] Specifically, the hydrogen concentration detection electrical signal output by the thermal conductivity sensor 5 is a weak electrical signal, and the signal processing device converts the weak electrical signal into a standard concentration signal to obtain the hydrogen concentration in the sample gas. At the same time, the signal processing device also realizes the calibration work of the sensor remotely.

[0109] The...

Embodiment 3

[0112] This embodiment provides a method for monitoring hydrogen concentration using the hydrogen concentration monitoring system of Embodiment 2, comprising the following steps:

[0113] Including system debugging and system running two processes. For specific gas flow direction, see figure 1 , where the large light-colored arrows indicate the flow direction of compressed air, the small arrows indicate the flow direction of sample gas, and the large dark-colored arrows indicate the flow direction of mixed gas.

[0114] S1: System debugging:

[0115] S1.1: Switch the second three-way valve 1 (three-way solenoid valve), so that its second air inlet is connected with its air outlet, and the standard gas source passes standard gas into the thermal conductivity sensor 5 to control the heat. After calibration, switch the second three-way valve 1 so that its first air inlet is connected with its air outlet;

[0116] S1.2: Open the external compressed air inlet valve, and open the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com