A kind of preparation technology of nanofiltration composite membrane

A preparation process and composite membrane technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve excellent comprehensive performance, improve water flux, and enhance membrane flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a preparation process of a nanofiltration composite membrane, comprising the following steps:

[0040] 1) After compounding the water phase solution on the non-woven fabric composite bottom film, and then compounding the oil phase solution, a semi-finished product is obtained;

[0041] 2) The semi-finished product obtained in the above steps is heat-treated in an oven, and the temperature of the membrane surface at the outlet of the oven is controlled by adjusting the wind speed and temperature of the oven to obtain a nanofiltration composite membrane;

[0042] The film surface temperature at the outlet of the oven is 20-30°C.

[0043] In the invention, the semi-finished product is obtained by first compounding the water phase solution on the non-woven fabric composite base film, and then compounding the oil phase solution.

[0044] In the present invention, the non-woven fabric composite base film preferably includes one or more of polysulfone, ...

Embodiment 1~9

[0093] The porous supporting membrane used is the ultrafiltration bottom membrane of polysulfone composite non-woven fabric.

[0094] Soak the base film in an aqueous phase solution containing 0.7wt% piperazine, 3wt% camphorsulfonic acid, and 0.02wt% sodium dodecyl sulfate for 10 seconds, then remove water by vacuum suction, and then pass through 42°C The heating roller further surface-dries the base film;

[0095] Then react with an oil phase solution containing 0.25wt% trimesoyl chloride in the oil phase coating area. The temperature of the oil phase solution is 50°C. After the initial reaction, it enters the HC oven for further reaction. After the reaction is completed, a layer of The PVA solution is then baked in an oven at 100°C for 2 minutes to finally form the desired finished nanofiltration membrane.

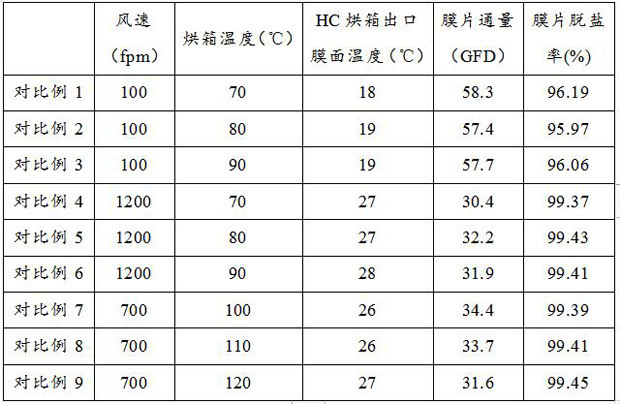

[0096] The nanofiltration composite membranes prepared in Examples 1 to 9 of the present invention were detected and process controlled.

[0097] See Table 1, Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com