High-breathability packaging material and preparation method thereof

A packaging material and air permeability technology, which is applied in the field of high air permeability packaging materials for medical device packaging and its preparation, can solve problems such as increasing the difficulty of sterilization, increasing production costs, and reducing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

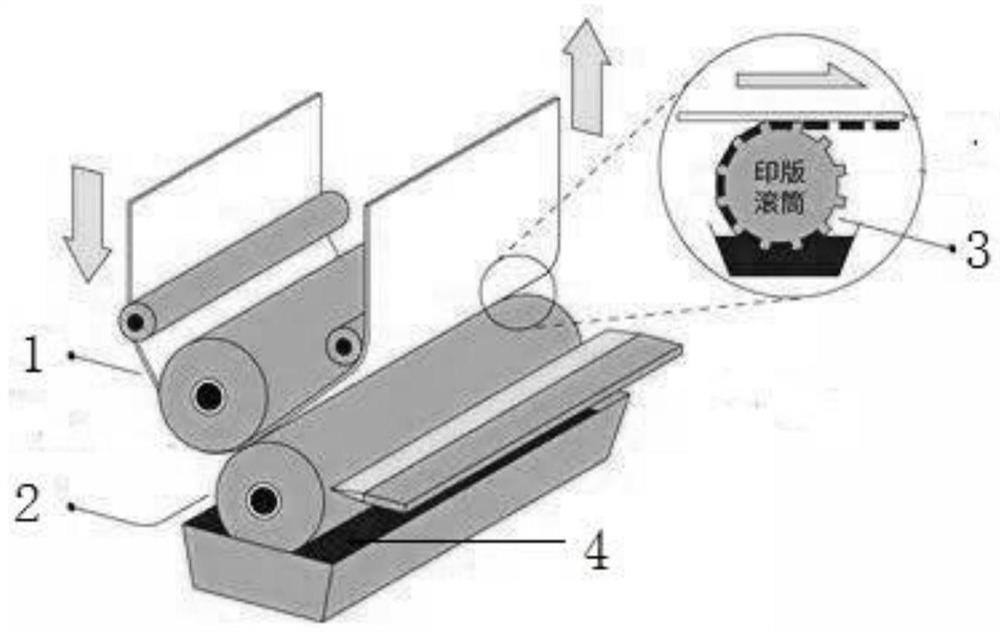

[0025] The present invention is a highly air-permeable packaging material. The film layer structure of the packaging material sequentially includes a first heat-sealing layer and a base material layer 1 from the inside to the outside; the base material layer is Tyvek; the first The heat-sealing layer is made of a material containing heat-sealing resin, and the material is coated on one or both sides of the substrate layer by gravure printing to form the first heat-sealing layer and / or the second heat-sealing layer respectively. .

[0026] The raw materials comprising the heat-sealing resin include 70% water-based EVA emulsion with a solid content of 40%, 20% water-based butyl rubber resin with a solid content of 65%, 7.6% inorganic filler, 2% Ammonia water, 0.2% dispersant, 0.2% defoamer. The dispersant includes aliphatic amides, such as ethylene bisstearic acid amide or stearic acid amide; polyethylene wax powder, polymer block copolymer, silicate dispersant, ammonium polyca...

Embodiment 2

[0033] The difference between Example 2 and Example 1 is that the raw materials containing the heat-sealing resin include 60% of water-based EVA emulsion with a solid content of 40%, 30% of water-based butyl resin with a solid content of 65%, in terms of weight percentage. Rubber resin, 5.4% inorganic filler, 3% ammonia water, 0.3% dispersant, 0.3% defoamer.

Embodiment 3

[0035]The difference between Example 3 and Example 1 is that the raw materials containing the heat-sealing resin include 56.4% of water-based EVA emulsion with a solid content of 40% and 30% of water-based butyl resin with a solid content of 65%. Rubber resin, 10% inorganic filler, 3% ammonia water, 0.3% dispersant, 0.3% defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com