Internal intersecting line fillet machining method

A processing method and intersecting line technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as inability to handle CNC machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] The internal intersecting line fillet processing method of the specific embodiment installs three-dimensional modeling programming software on the computer, and the present embodiment takes software CimatronE 11.0 as an example, and the method includes the following process steps:

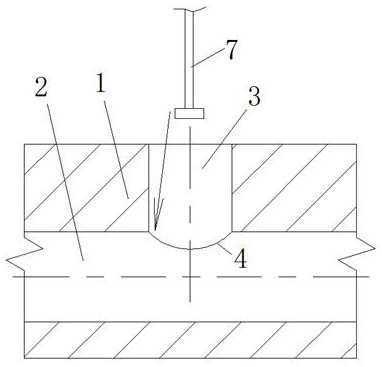

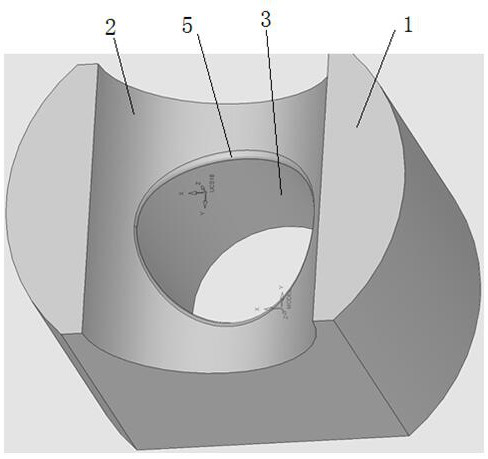

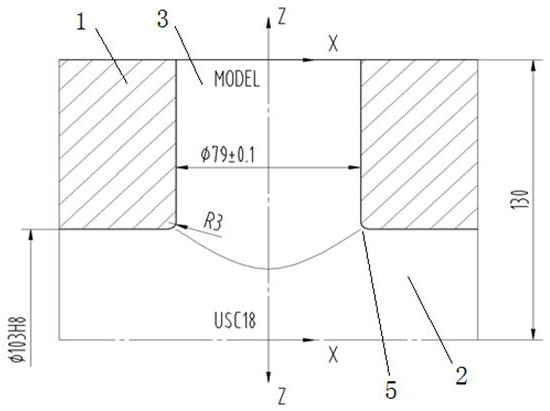

[0036] 1) On the computer, run CimatronE 11.0 to perform 3D modeling and build a 3D model, refer to figure 1 The built three-dimensional model includes a base body 1, and the base body 1 is provided with a main channel hole 2 and a lateral hole 3 intersecting with the main channel hole 2 on the radial side of the main channel hole 2, and the lateral hole 3 and the main channel The axes of the holes 2 intersect and are perpendicular to each other; the inner end of the lateral hole 3 and the inner wall of the main channel hole 2 form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com