Method for processing silicon carbide sealing ring part by single electrode air plasma

A plasma and sealing ring technology, which is applied in electrical components, plasma welding equipment, metal processing equipment, etc., can solve the problem of difficult processing of silicon carbide sealing ring parts, and achieve good consistency in processing quality and stable and controllable processing , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

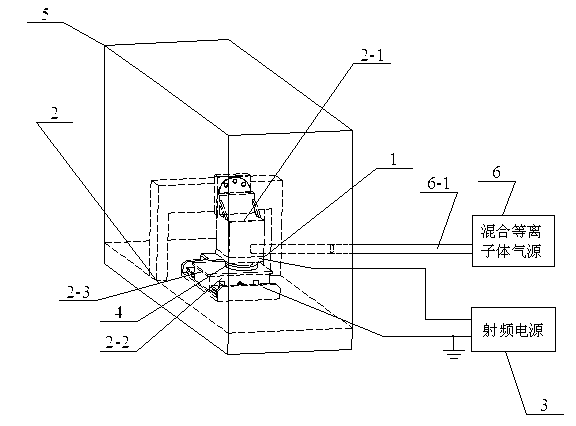

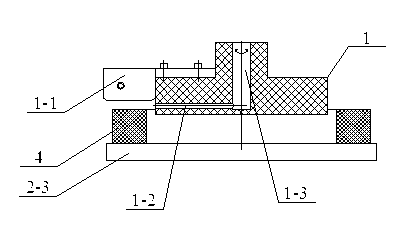

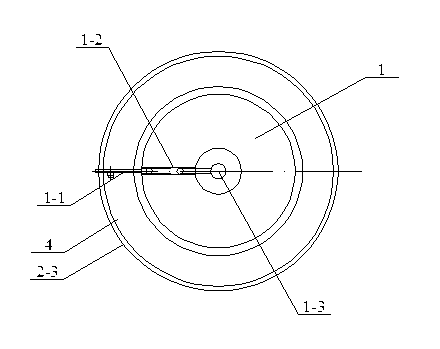

[0023] Specific implementation mode one: combine figure 1 , figure 2 , image 3 As shown, its steps are:

[0024] Step 1: Insulate and connect the upper end surface of the disc-shaped electrode holder 1 to the vertically moving working shaft 2-1 of the gantry processing machine tool 2, and a sheet-shaped electrode 1 is vertically arranged on the outer surface of the disc-shaped electrode holder 1 -1, the straight line where the sheet-shaped electrode 1-1 and the diameter of the disk-shaped electrode holder 1 are located is collinear, so that the sheet-shaped electrode 1-1 is connected to the output end of the radio frequency power supply 3 through the disk-shaped electrode holder 1 as atmospheric plasma discharge The anode of the anode; the air outlet hole 1-2 on the disc-shaped electrode frame 1 passes through the gas guide hole 1-3 in the center of the disc-shaped electrode frame 1, and the gas pipe 6-1 communicates with the mixed plasma gas source 6. The disc-shaped elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com