Pervious concrete and preparation method thereof

A technology of permeable concrete and cement, applied in the field of building materials, can solve the problems of reduced strength, easy water loss, flowing slurry, etc., and achieve the effect of good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

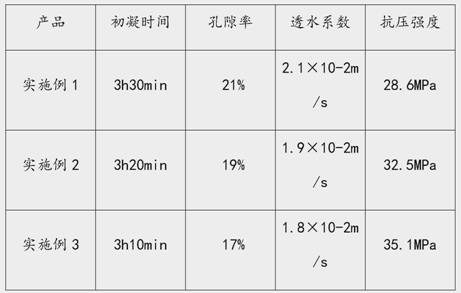

Embodiment 1

[0027] The permeable concrete of the present invention is made of the following components in proportion by weight:

[0028] 200 parts of cement, 30 parts of mineral powder, 30 parts of fly ash, 1400 parts of crushed stone, 1 part of rubber powder, 0.5 part of cellulose and cellulose ether, 0.5 part of starch ether, 3 parts of admixture, 57 parts of water.

[0029] Among the above components, the particle size of crushed stone is between 5-25mm, the porosity is greater than 44%, the cement is P.O42.5 cement, and the mineral powder is S95 blast furnace slag powder. Pour cement, mineral powder, fly ash, crushed stone, and starch ether into the mixer for premixing, then weigh the rubber powder, cellulose, cellulose ether, and admixture, mix them in water, and slowly pour them into the mixer During the process, observe the grouting effect on the surface of the crushed stone. When the surface of the crushed stone shows a metallic luster, it can be directly pressed or transported to...

Embodiment 2

[0031] The permeable concrete of the present invention is made of the following components in proportion by weight:

[0032] 250 parts of cement, 55 parts of mineral powder, 55 parts of fly ash, 1550 parts of gravel, 3 parts of rubber powder, 2.75 parts of cellulose and cellulose ether, 2.75 parts of starch ether, 3.5 parts of admixture, 70.5 parts of water.

[0033] Among the above components, the particle size of crushed stone is between 5-25mm, the porosity is greater than 44%, the cement is P.O42.5 cement, and the mineral powder is S95 blast furnace slag powder. Pour cement, mineral powder, fly ash, crushed stone, and starch ether into the mixer for premixing, then weigh the rubber powder, cellulose, cellulose ether, and admixture, mix them in water, and slowly pour them into the mixer During the process, observe the grouting effect on the surface of the crushed stone. When the surface of the crushed stone shows a metallic luster, it can be directly pressed or transported ...

Embodiment 3

[0035] The permeable concrete of the present invention is made of the following components in proportion by weight:

[0036] 300 parts of cement, 80 parts of mineral powder, 80 parts of fly ash, 1700 parts of crushed stone, 5 parts of rubber powder, 5 parts of cellulose and cellulose ether, 5 parts of starch ether, 4 parts of admixture, and 84 parts of water.

[0037] Among the above components, the particle size of crushed stone is between 5-25mm, the porosity is greater than 44%, the cement is P.O42.5 cement, and the mineral powder is S95 blast furnace slag powder. Pour cement, mineral powder, fly ash, crushed stone, and starch ether into the mixer for premixing, then weigh the rubber powder, cellulose, cellulose ether, and admixture, mix them in water, and slowly pour them into the mixer During the process, observe the grouting effect on the surface of the crushed stone. When the surface of the crushed stone shows a metallic luster, it can be directly pressed or transported...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com