A self-installing and self-recovering microseismic sensor device

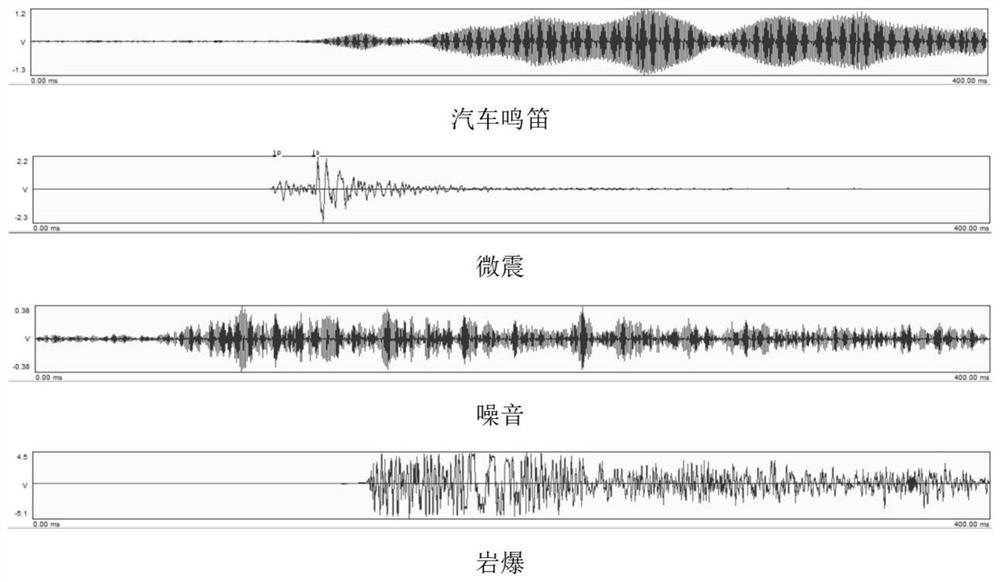

A microseismic sensor and self-recovery technology, which is applied in the field of geotechnical engineering, can solve problems such as difficult maintenance, affecting monitoring quality, and delaying workers' construction, and achieves the effects of simple construction procedures, good monitoring effects, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

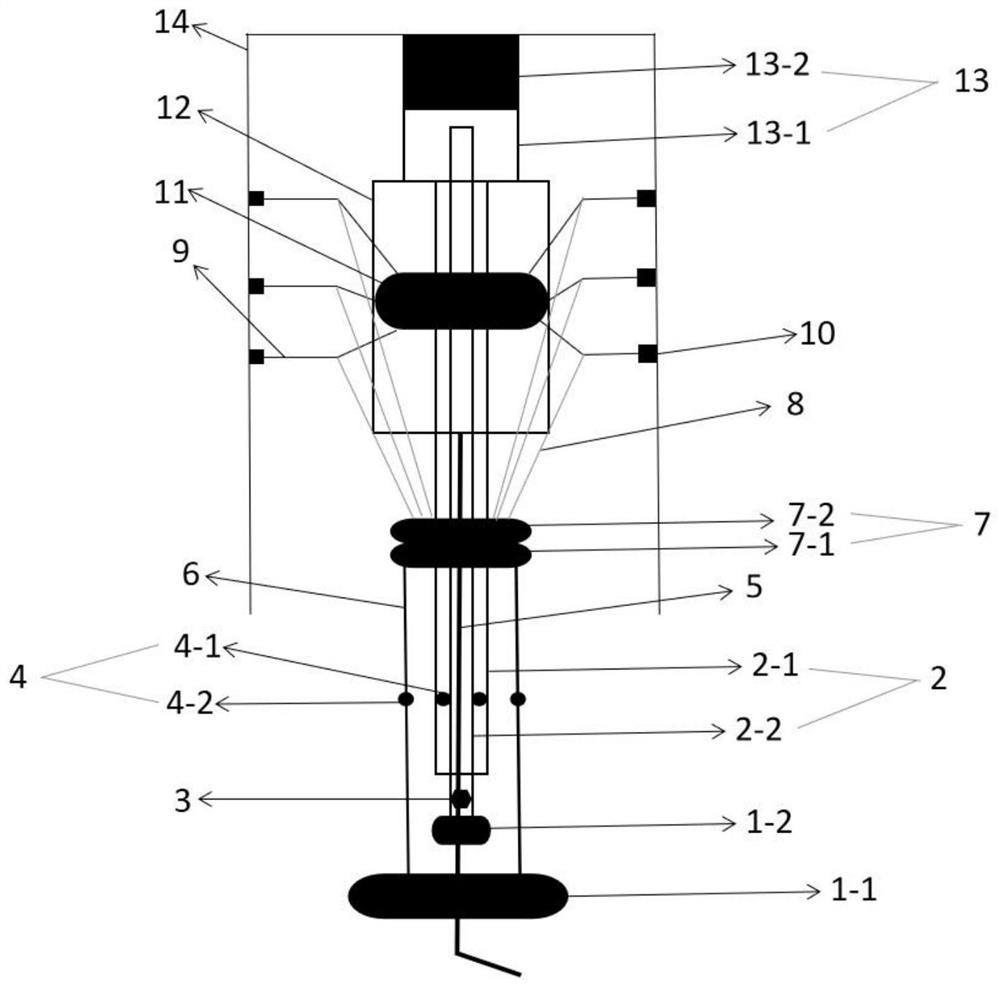

[0025] A self-installation and self-recovery microseismic sensor device, comprising: handle A1-1, handle B1-2, outer middle rod 2-1, inner middle rod 2-2, dynamometer 3, expansion joint 4, cable 5, The thrust rod 6, the connecting plate 7, the elastic rod 8, the bracket 9, the elastic film 10, the fixed disk 11, the sensor 12, the elastic probe 13, the handle A1-1 are connected with the thrust rod 6, and the thrust rod 6 Connected with the connecting plate 7, the connecting plate 7 is connected with the elastic rod 8, the elastic rod 8 is connected with a plurality of the brackets 9, one end of the bracket 9 is connected with the fixed plate 11, and the other end is connected with the fixed plate 11. The elastic film 10 is connected; the handle B1-2 is connected with the inner middle rod 2-2, the inner middle rod 2-2 is built in the outer middle rod 2-1, and the connecting plate 7 is connected to the inner middle rod 2-2. The outer middle rod 2-1 built in the thrust rod 6 is m...

Embodiment 2

[0032] A self-installation and self-recovery microseismic sensor device includes four systems, namely a control system, a monitoring system, a fixing system and a force transmission system.

[0033] 1 The control system includes: handle A1-1, handle B1-1, middle rod 2 including outer middle rod 21-, inner middle rod 2-2, dynamometer 3, expansion joint 4 including middle rod expansion joint 4-1, thrust Rod expansion section 4-2.

[0034] 2. The monitoring system includes: cable 5, sensor 12, elastic force probe 13 including elastic force chamber 13-1 and sensitive probe 13-2.

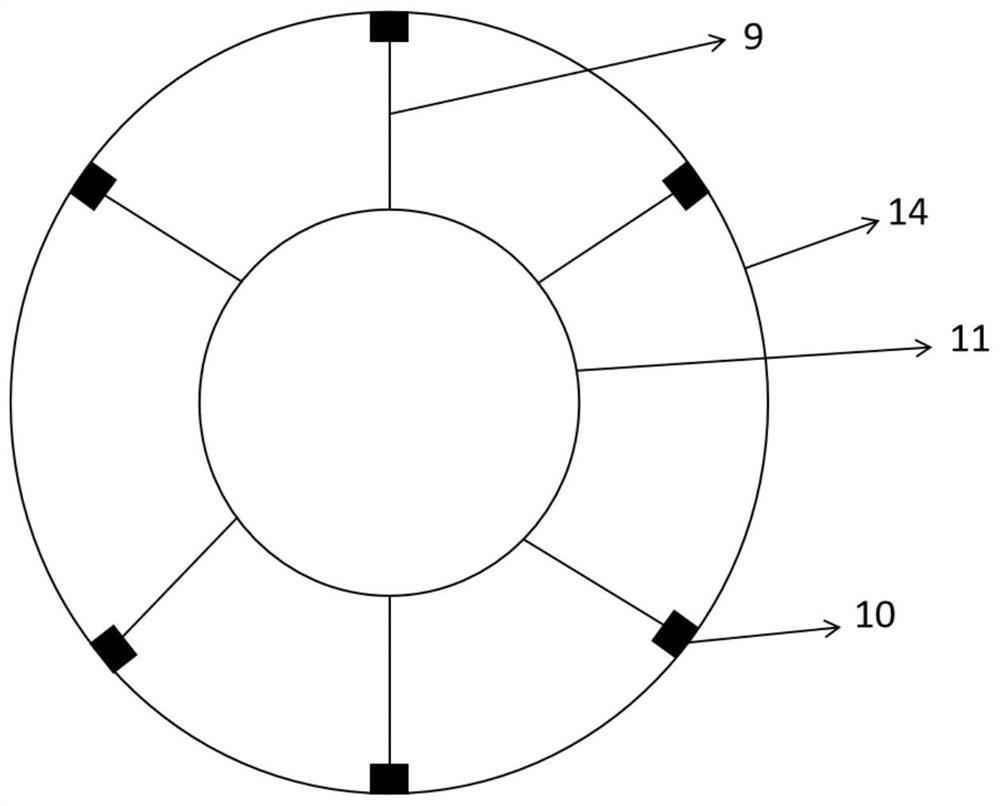

[0035] 3. The fixing system includes: a bracket 9 , an elastic film 10 , and a fixing plate 11 .

[0036] 4. The force transmission system includes: thrust rod 6, connecting disk 7, connecting disk bottom 7-1, connecting disk top 7-2, and elastic rod 8.

[0037] The handle A1-1 is connected with the thrust rod 6, the thrust rod 6 is connected with the connecting plate 7, the connecting disk 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com