A kind of fixed-point application method of low diffusivity organic fertilizer

An application method and organic fertilizer technology, applied in fertilization methods, organic fertilizers, bio-organic part treatment, etc., can solve the problems of nutrient waste, limited absorption capacity and range of crop roots, and increased demand for organic fertilizers, etc., to improve penetration Barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

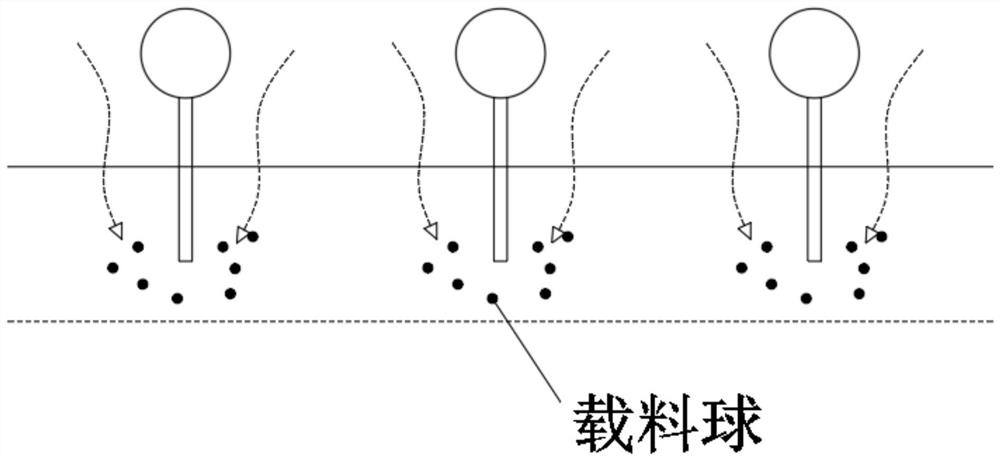

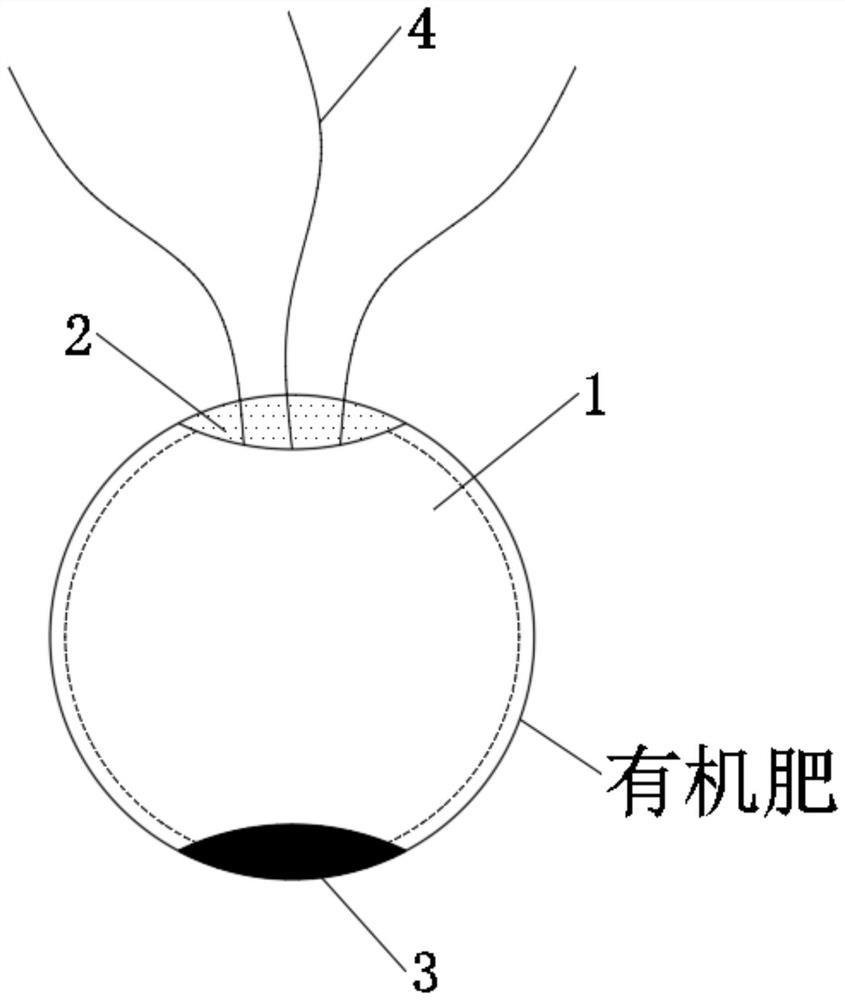

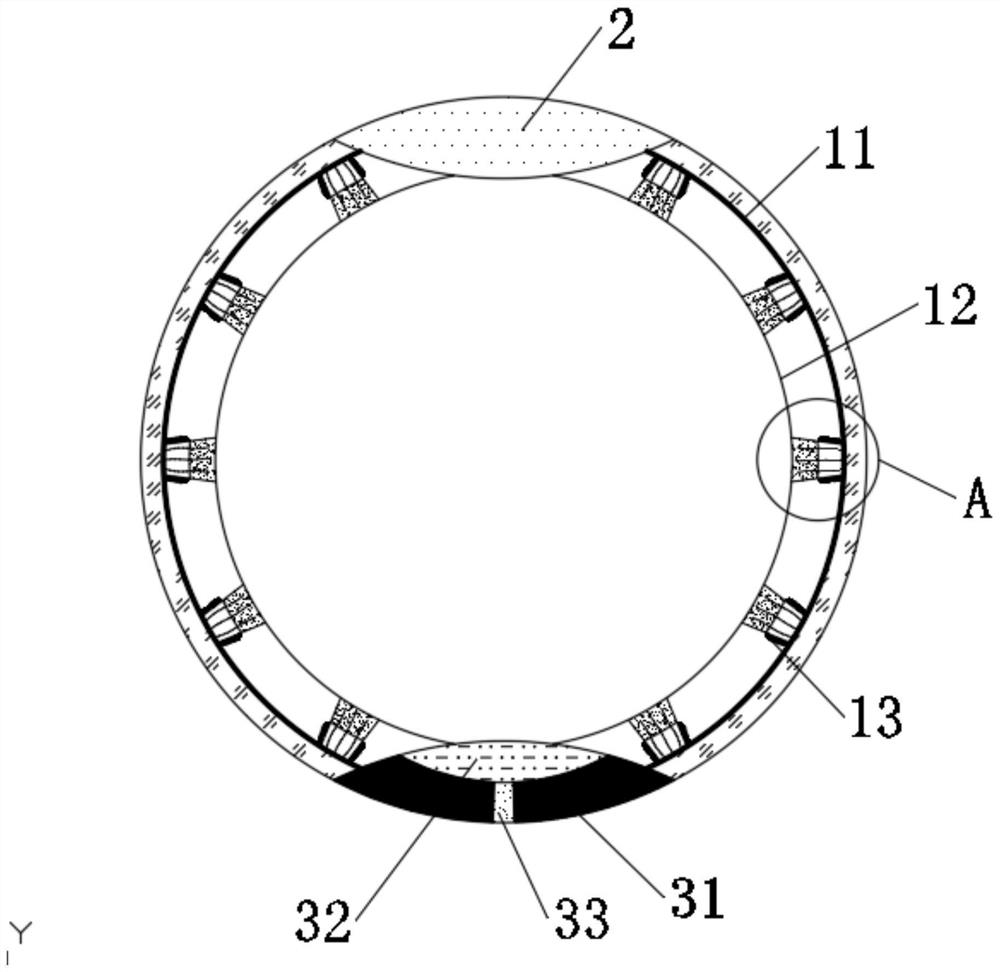

[0043] see Figure 1-2 , a fixed-point application method of low diffusivity organic fertilizer, comprising the following steps:

[0044] S1. Prepare the following raw materials in parts by weight: 15 parts of pig manure, 10 parts of pond sludge, 15 parts of corn stalks, 2 parts of attapulgite powder, 6 parts of phosphate rock powder, 6 parts of humic acid, 10 parts of soybean meal, sugar 3 parts and 0.6 parts of starter;

[0045] S2. Take the above raw materials, mix them to remove attapulgite powder and phosphate rock powder, and place them in a fermentation chamber for sealed fermentation, wherein the fermentation temperature is 35° C., and the fermentation time is 36 hours;

[0046] S3. After the fermentation is finished, mix with attapulgite powder and phosphate rock powder to prepare organic fertilizer, and then cover the organic fertilizer on the outer surface of the carrier ball and dry and attach it;

[0047] S4. Embedding the carrier ball at the root of the crop in...

Embodiment 2

[0059] A fixed-point application method of low diffusivity organic fertilizer, comprising the following steps:

[0060] S1. Prepare the following raw materials in parts by weight: 20 parts of pig manure, 14 parts of pond sludge, 20 parts of corn stalks, 5 parts of attapulgite powder, 8 parts of phosphate rock powder, 8 parts of humic acid, 12 parts of soybean meal, sugar 4 parts and 0.9 parts of starter;

[0061] S2. Take the above raw materials, mix them to remove attapulgite powder and phosphate rock powder, and place them in a fermentation chamber for sealed fermentation, wherein the fermentation temperature is 40° C., and the fermentation time is 42 hours;

[0062] S3. After the fermentation is finished, mix with attapulgite powder and phosphate rock powder to prepare organic fertilizer, and then cover the organic fertilizer on the outer surface of the carrier ball and dry and attach it;

[0063] S4. Embedding the carrier ball at the root of the crop in the soil at a fixe...

Embodiment 3

[0067] A fixed-point application method of low diffusivity organic fertilizer, comprising the following steps:

[0068] S1. Prepare the following raw materials in parts by weight: 25 parts of pig manure, 18 parts of pond sludge, 25 parts of corn stalks, 8 parts of attapulgite powder, 10 parts of phosphate rock powder, 12 parts of humic acid, 14 parts of soybean meal, sugar 5 parts and starter culture 1.2 parts;

[0069] S2. Take the above raw materials, mix them to remove attapulgite powder and phosphate rock powder, and place them in a fermentation chamber for sealed fermentation, wherein the fermentation temperature is 45° C., and the fermentation time is 48 hours;

[0070] S3. After the fermentation is finished, mix with attapulgite powder and phosphate rock powder to prepare organic fertilizer, and then cover the organic fertilizer on the outer surface of the carrier ball and dry and attach it;

[0071] S4. Embedding the carrier ball at the root of the crop in the soil at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com