Preparation method of onion spare rib sauce

A technology of onion and ribs, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve problems such as unfavorable development of onion processing industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

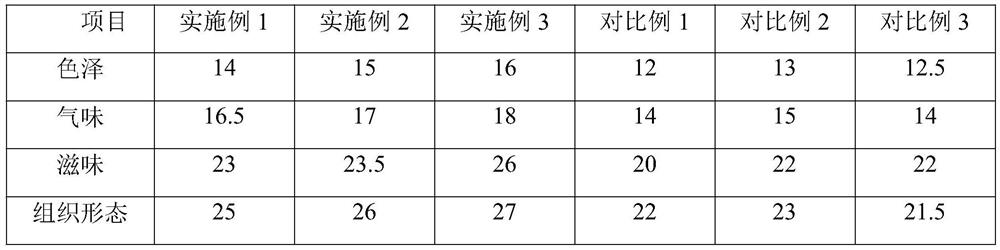

Embodiment 1

[0022] The preparation of embodiment 1 onion ribs sauce

[0023] (1) Onion pretreatment: Select onions with smooth surface and no lesions, remove the outer skin, wash and cut into pieces, blanching in hot water at 90°C for 50 seconds, drain and rinse with cold water for 30 seconds. The onion is placed in a blender, and the compound color-protecting agent (ascorbic acid: vitamin C: apigenin=3:1:1) that is made up of ascorbic acid, vitamin C and apigenin is added by the standard of every 80g onion adding 2g color-protecting agent , weight ratio), crushed for 2 minutes.

[0024] (2) Garlic pretreatment: cut the garlic into fine granules, put it into a grinder, and grind it for 1 minute.

[0025] (3) Cooking and boiling: add 8g of soybean oil after preheating the pan, keep the oil temperature at 110°C, add 50g of pretreated onion and 9g of pretreated garlic and stir-fry for 2 minutes; add 20g of tomato paste and 8g of white sugar , 3g bean paste, 4g oil consumption, 4g salt and ...

Embodiment 2

[0027] The preparation of embodiment 2 onion ribs sauce

[0028] (1) Onion pretreatment: Select onions with smooth surface and no lesions, remove the outer skin, wash and cut into pieces, blanching in 80°C hot water for 70 seconds, drain and rinse with cold water. The onion is placed in a blender, and the compound color-protecting agent (ascorbic acid: vitamin C: apigenin=3:1:1) that is made up of ascorbic acid, vitamin C and apigenin is added by the standard of every 90g onion adding 2g color-protecting agent , weight ratio), crushed for 4 minutes.

[0029] (2) Garlic pretreatment: cut the garlic into fine granules, put it into a grinder, and grind it for 3 minutes.

[0030] (3) Cooking and boiling: add 8g of soybean oil after preheating the pan, keep the oil temperature at 110°C, add 55g of pretreated onions and 7g of pretreated garlic and stir-fry for 2 minutes; add 20g of tomato paste and 15g of white sugar , 3g bean paste, 4g oil consumption, 5g salt and 2g vinegar, the...

Embodiment 3

[0032] The preparation of embodiment 3 onion ribs sauce

[0033] (1) Onion pretreatment: select onions with smooth surface and no lesions, remove the outer skin, wash and cut into pieces, blanching in hot water at 85°C for 60 seconds, drain and rinse with cold water. The onion is placed in a blender, and the compound color-protecting agent (ascorbic acid: vitamin C: apigenin=3:1:1) that is made up of ascorbic acid, vitamin C and apigenin is added by the standard of every 85g onion adding 2g color-protecting agent , weight ratio), crushed for 3 minutes.

[0034] (2) Garlic pretreatment: cut the garlic into fine granules, put it into a grinder, and grind it for 2 minutes.

[0035] (3) Cooking and boiling: add 8g of soybean oil after preheating the pan, keep the oil temperature at 110°C, add 60g of pretreated onions and 5g of pretreated garlic and stir-fry for 2 minutes; add 25g of tomato paste and 6g of white sugar , 3g bean paste, 4g oil consumption, 5g salt and 2g vinegar, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com