Manufacturing method of silica gel navel-protecting patch

A technology of silicone gel and umbilical sticks, applied in medical science, bandages, absorbent pads, etc., can solve problems such as baby pain, bacterial growth, and infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

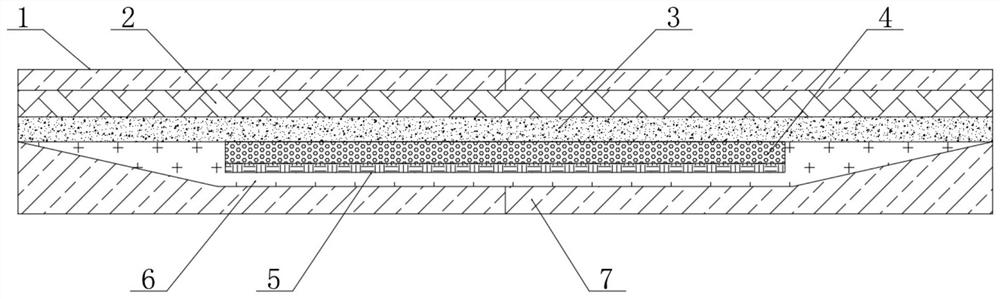

[0024] see figure 1 , in the embodiment of the present invention, a silicone gel umbilical patch, including centrifugal paper I1, the lower surface of the centrifugal paper I1 is bonded with a backing layer 2, and the lower surface of the backing layer 2 is coated with a silicone gel layer 3 , the lower surface of the silicone gel layer 3 is bonded with an absorbent pad 4, the lower surface of the absorbent pad 4 is bonded with a PE film 5, the lower surface of the PE film 5 is bonded with a release layer 6, and the lower surface of the release layer 6 Centrifugal paper II7 is glued together, and the middle sections of centrifugal paper II7 and centrifugal paper I1 are both provided with easy-tear openings.

[0025] Further, the easy-tear opening adopts an "S" shape.

[0026] Further, the absorbent pad 4 adopts any one of square, rectangular, rhombus, round, oval, heart-shaped and flower-shaped.

[0027] Further, the centrifugal paper II7 and the centrifugal paper I1 are bot...

Embodiment 2

[0040] see figure 1 , in the embodiment of the present invention, a silicone gel umbilical patch, including centrifugal paper I1, the lower surface of the centrifugal paper I1 is bonded with a backing layer 2, and the lower surface of the backing layer 2 is coated with a silicone gel layer 3 , the lower surface of the silicone gel layer 3 is bonded with an absorbent pad 4, the lower surface of the absorbent pad 4 is bonded with a PE film 5, the lower surface of the PE film 5 is bonded with a release layer 6, and the lower surface of the release layer 6 Centrifugal paper II7 is glued together, and the middle sections of centrifugal paper II7 and centrifugal paper I1 are both provided with easy-tear openings.

[0041] Further, the easy-tear opening adopts an "I" shape.

[0042] Further, the absorbent pad 4 adopts any one of square, rectangular, rhombus, round, oval, heart-shaped and flower-shaped.

[0043] Further, the materials of the centrifugal paper II7 and the centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com