Electron beam projectile body grooving fragment control method

A control method and electron beam technology, applied in the field of electron beam projectile notch and fragment control, can solve the problems of low projectile carrying capacity, poor process consistency, low production efficiency, etc., and achieve simple processing, lower cost-effectiveness ratio, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

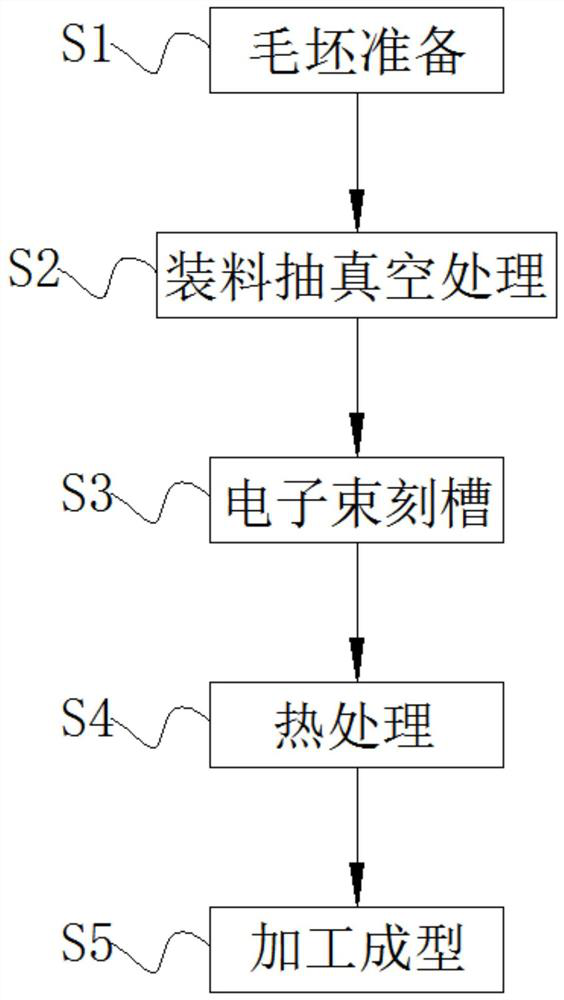

[0040] A method for controlling the notched fragments of an electron beam projectile body, specifically comprising the following steps:

[0041] S1. Blank preparation: According to the requirements of the actual ammunition drawings, use stamping equipment to process the blank of the projectile body, control the material within the specified hardness range through heat treatment, leave a margin of 0.5mm for rough machining of the projectile body, heat treatment temperature is 550°C, and the stamping equipment is modeled as MODEL stamping machine;

[0042] S2, charging and vacuuming treatment: insert the projectile blank in step S1 into the tooling of the electron beam equipment, and vacuumize, and the electron beam equipment is an electron beam welder whose model is THDW;

[0043] S3. Electron beam grooving: after the vacuuming in step S2 meets the requirements, start the body grooving program, and use electron beams to carve grooves on the outer surface of the projectile with ...

Embodiment 2

[0047] A method for controlling the notched fragments of an electron beam projectile body, specifically comprising the following steps:

[0048] S1. Blank preparation: According to the requirements of the live ammunition drawings, use stamping equipment to process the blank of the projectile body, control the material within the specified hardness range through heat treatment, leave a margin of 0.2mm for the rough machining of the projectile body, and heat treatment temperature is 500 ° C. The stamping equipment adopts the model of MODEL stamping machine;

[0049] S2, charging and vacuuming treatment: insert the projectile blank in step S1 into the tooling of the electron beam equipment, and vacuumize, and the electron beam equipment is an electron beam welder whose model is THDW;

[0050]S3. Electron beam grooving: When the vacuuming in step S2 meets the requirements, start the projectile body grooving program, and use electron beams to carve grooves on the outer surface of t...

Embodiment 3

[0054] A method for controlling the notched fragments of an electron beam projectile body, specifically comprising the following steps:

[0055] S1. Blank preparation: According to the requirements of the live ammunition drawing, use stamping equipment to process the blank of the projectile body, control the material within the specified hardness range through heat treatment, leave a margin of 1 mm for the rough machining of the projectile body, and heat treatment temperature is 650 ° C. The stamping equipment is MODEL punching machine;

[0056] S2, charging and vacuuming treatment: insert the projectile blank in step S1 into the tooling of the electron beam equipment, and vacuumize, and the electron beam equipment is an electron beam welder whose model is THDW;

[0057] S3. Electron beam grooving: when step S2 is vacuumed to meet the requirements, start the projectile body grooving program, and use electron beams to carve grooves on the outer surface of the projectile with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com