High-performance nitrile rubber material and preparation method thereof

A technology for high-performance nitrile-butadiene and rubber materials, applied in the rubber field, can solve the problems of complex preparation steps and too many types of fillers, and achieve the effects of broad application prospects, simple preparation methods and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

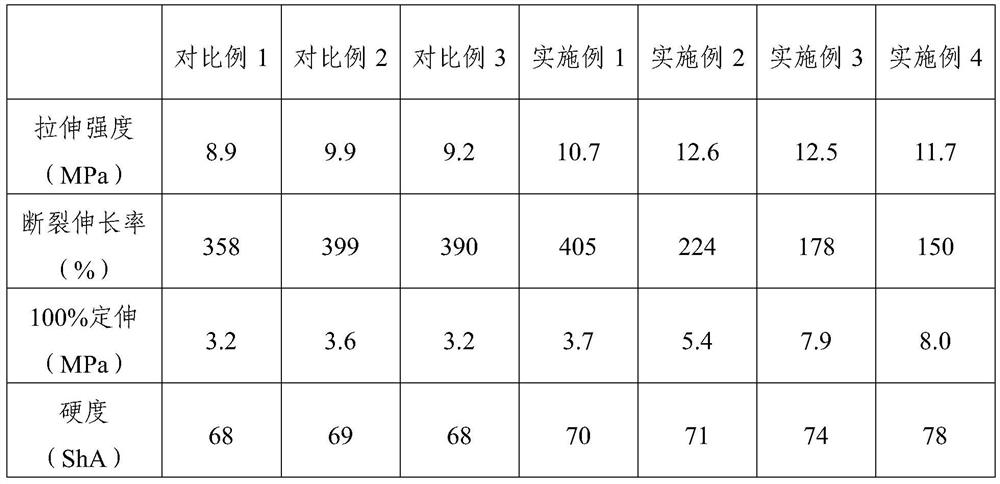

[0044] The present embodiment provides a high-performance nitrile rubber material, which is prepared from the following raw materials in parts by weight: 70 parts of carboxylated nitrile rubber, 30 parts of methyl vinyl silicone rubber, 0.5 part of carbon quantum dots, 50 parts of white carbon black, Double 2,5 1 part; the particle size of the carbon quantum dot is 1-3nm.

[0045] Present embodiment provides the preparation method of above-mentioned high-performance nitrile rubber material simultaneously, specifically comprises the following steps (adopting wet mixing):

[0046] (1) Methyl vinyl silicone rubber is dissolved in methylene chloride to obtain a silicone rubber solution with a mass solubility of 9%;

[0047] (2) adding carbon quantum dots to the silicone rubber solution to obtain a mixed solution;

[0048] (3) The mixed solution is dried, and the dried mixture and carboxylated nitrile rubber are added in the internal mixer, and then white carbon black and double 2...

Embodiment 2

[0051] The present embodiment provides a high-performance nitrile rubber material, which is prepared from the following raw materials in parts by weight: 70 parts of carboxylated nitrile rubber, 30 parts of methyl vinyl silicone rubber, 1 part of carbon quantum dots, 50 parts of white carbon black, Double 2,5 1 part; the particle size of the carbon quantum dot is 1-3nm.

[0052] The preparation method of the high-performance nitrile rubber material provided in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0054] The present embodiment provides a high-performance nitrile rubber material, which is prepared from the following raw materials in parts by weight: 70 parts of carboxylated nitrile rubber, 30 parts of methyl vinyl silicone rubber, 3 parts of carbon quantum dots, 50 parts of white carbon black, Double 2,5 1 part; the particle size of the carbon quantum dot is 1-3nm.

[0055] The preparation method of the high-performance nitrile rubber material provided in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

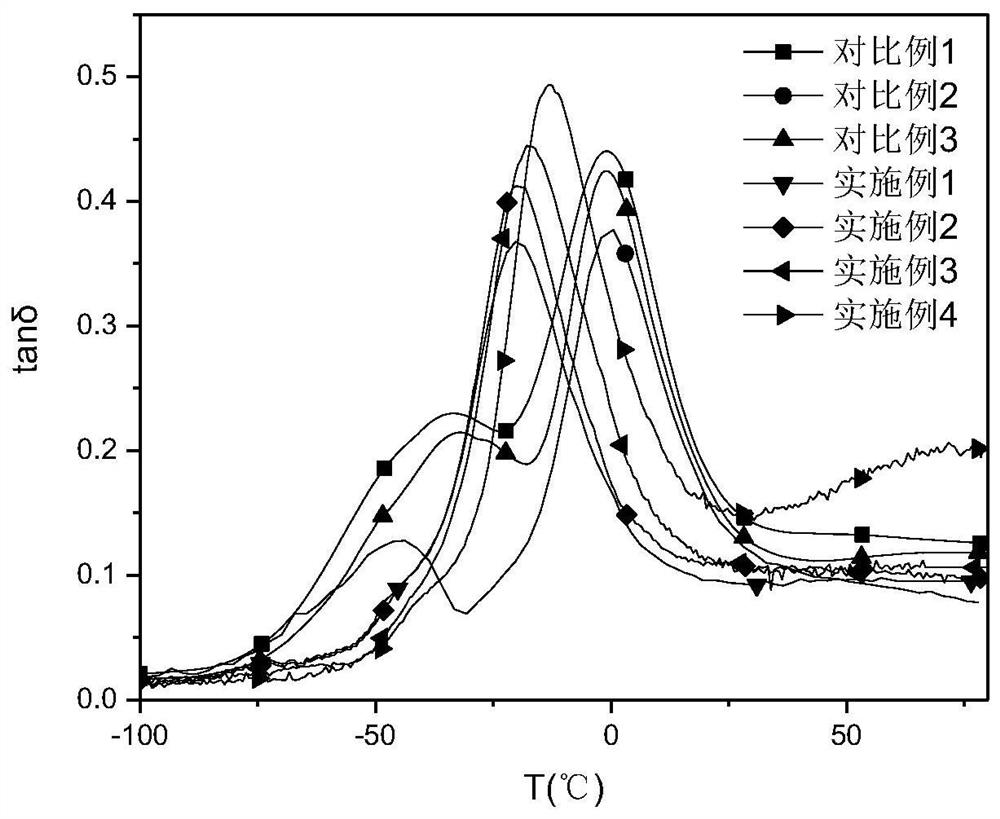

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com