Hybrid fiber multi-scale reinforced NAO type brake friction material and preparation method thereof

A brake friction material and mixed fiber technology, which is applied in the field of friction materials, can solve the problems of high density and hardness, poor mixing effect of mixed fibers, brake dust and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

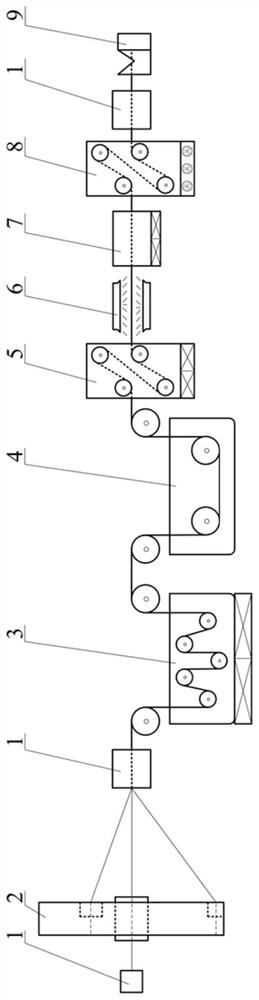

Method used

Image

Examples

Embodiment 1

[0035] 1. A hybrid fiber multi-scale reinforced NAO brake friction material, characterized in that the hybrid fiber multi-scale reinforced NAO brake friction material is calculated by mass fraction, and the content of each component is: hybrid fiber multi-scale reinforcement 6%, Cashew nut shell oil modified phenolic resin 0%, precipitated barium sulfate 15%, wollastonite 16%, potassium titanate lamellae 20%, antimony sulfide 12%, natural graphite 20%, molybdenum disulfide 5%, cashew nut shell oil friction Powder 6%; wherein the mixed fiber multi-scale reinforcement is composed of aramid fibers with a mass fraction of 30% and natural fibers with a mass fraction of 70%, wherein the natural fibers include jute fibers, kenaf fibers and abaca fibers, three natural fibers The mass fraction ratio is 1:1:1.

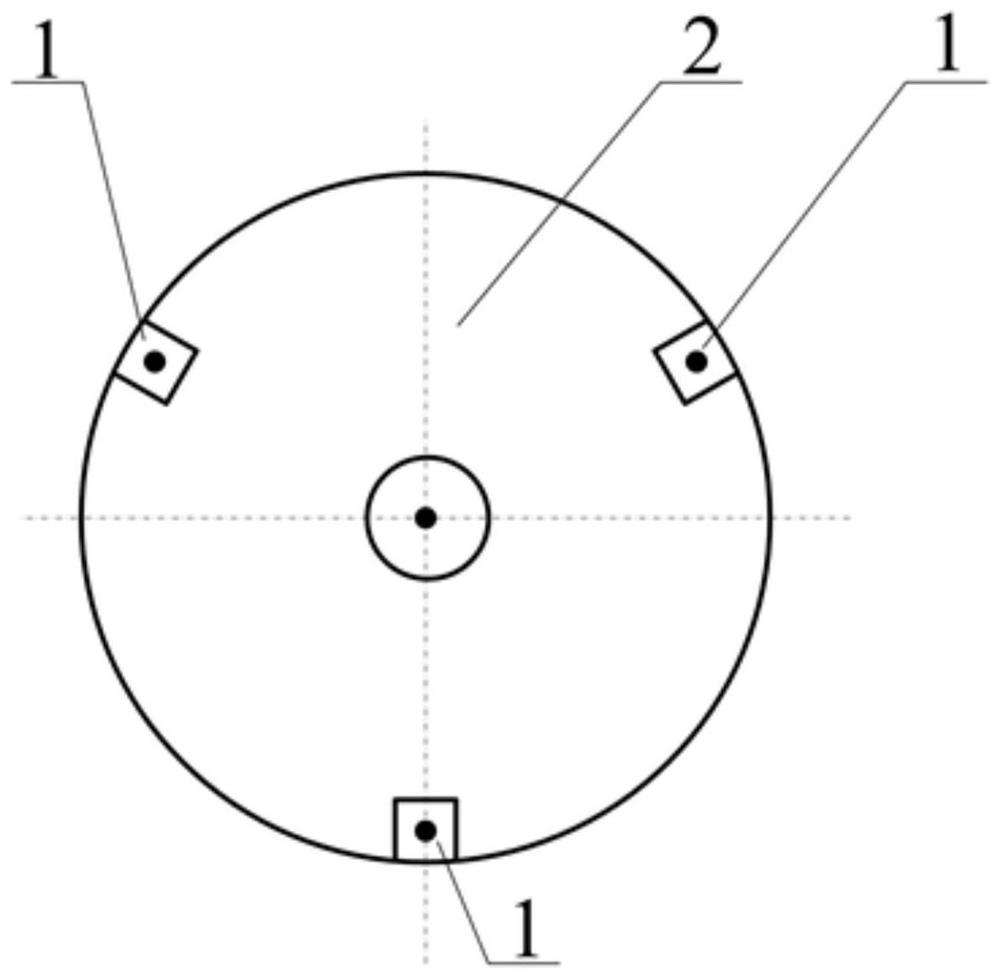

[0036] 2 Preparation of hybrid fiber multi-scale reinforced NAO type brake friction material The hybrid fiber multi-scale reinforcement is obtained through the following steps: ...

Embodiment 2

[0043] 1 A hybrid fiber multi-scale reinforced NAO brake friction material, characterized in that the hybrid fiber multi-scale reinforced NAO brake friction material contains the following components by mass fraction: hybrid fiber multi-scale reinforcement 23%, cashew nut shell oil Modified phenolic resin 30%, precipitated barium sulfate 8%, wollastonite 5%, potassium titanate lamellae 8%, antimony sulfide 6%, natural graphite 11%, molybdenum disulfide 4%, cashew nut shell oil friction powder 5% ; Wherein the hybrid fiber multi-scale reinforcement is composed of 60% aramid fiber by mass fraction and 40% natural fiber by mass fraction, wherein the natural fibers include ramie fiber, kenaf fiber and flax fiber, the mass fraction ratio of the three natural fibers 1:1:1.

[0044] 2. Preparation of hybrid fiber multi-scale reinforced NAO type brake friction material. The hybrid fiber multi-scale reinforcement is prepared by the following steps: three continuous natural aramid fiber...

Embodiment 3

[0051] 1 A hybrid fiber multi-scale reinforced NAO brake friction material, characterized in that the hybrid fiber multi-scale reinforced NAO brake friction material contains the following components by mass fraction: hybrid fiber multi-scale reinforcement 6%, cashew nut shell oil Modified phenolic resin 40%, precipitated barium sulfate 19%, wollastonite 24%, potassium titanate lamellae 5%, antimony sulfide 2%, natural graphite 2%, molybdenum disulfide 1%, cashew nut shell oil friction powder 1% ; Wherein the hybrid fiber multi-scale reinforcement is composed of aramid fibers with a mass fraction of 40% and natural fibers with a mass fraction of 60%, wherein the natural fibers include jute fibers, abaca fibers and cotton fibers, and the mass fraction ratio of the three natural fibers 1:1:1.

[0052] 2 Preparation of hybrid fiber multi-scale reinforced NAO type brake friction material, the hybrid fiber multi-scale reinforcement is prepared through the following steps:

[0053] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com