Heat-sealing-resistant water-based ink and preparation method thereof

A water-based ink and heat-resistant technology, which is used in the field of heat-resistant sealing water-based ink and the preparation of heat-resistant sealing water-based ink, can solve the problems of ink falling off, full of ink, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

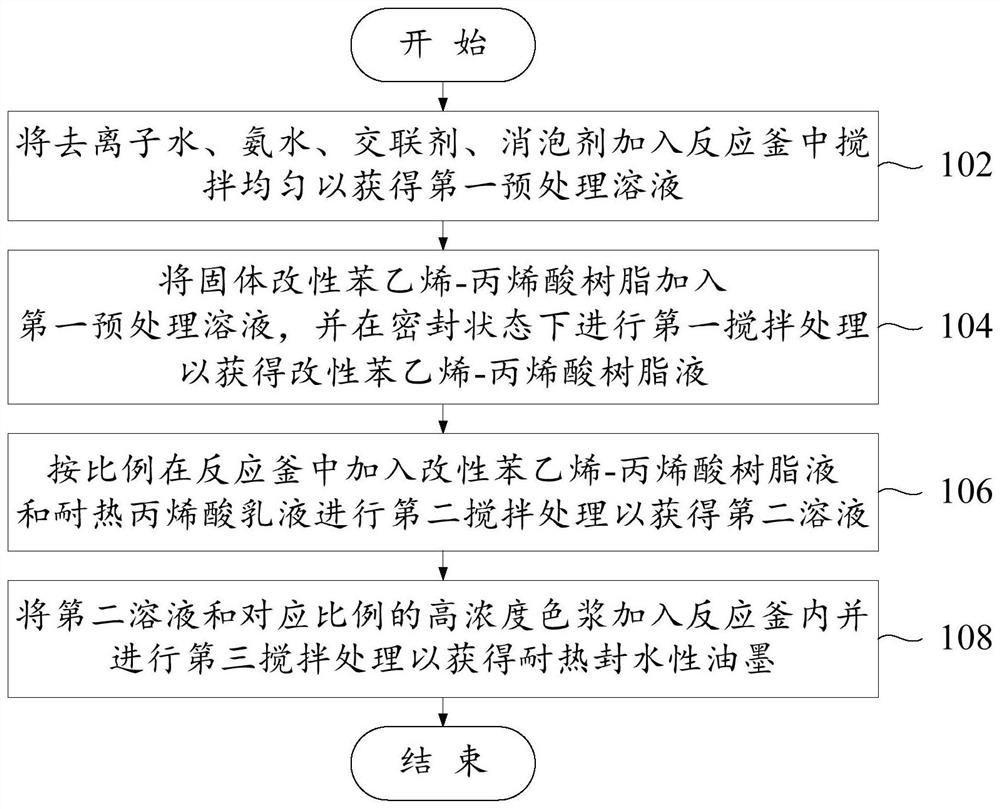

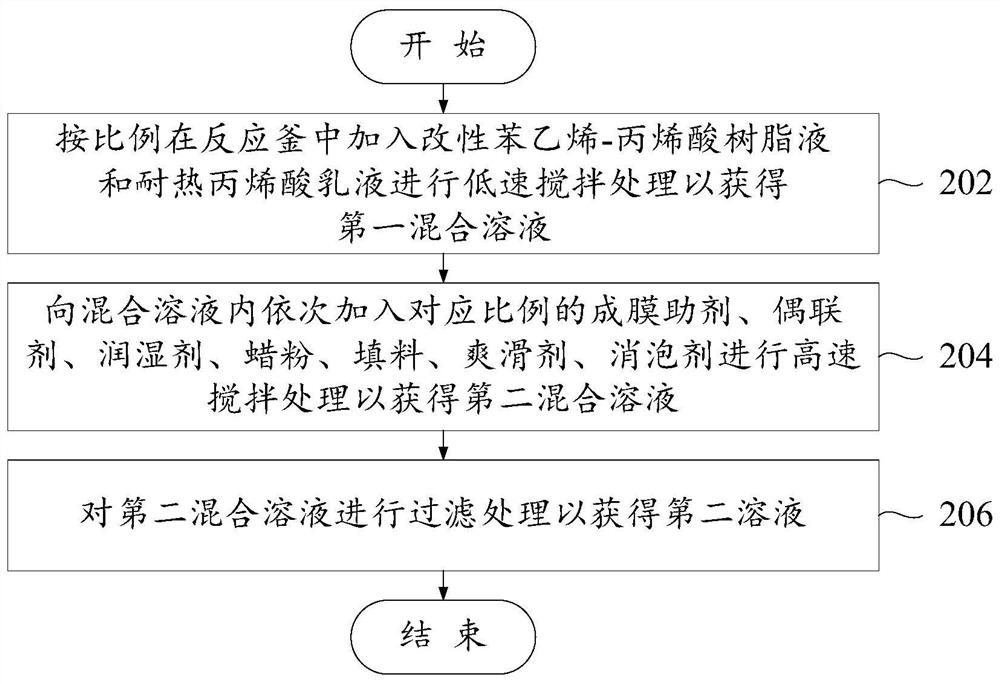

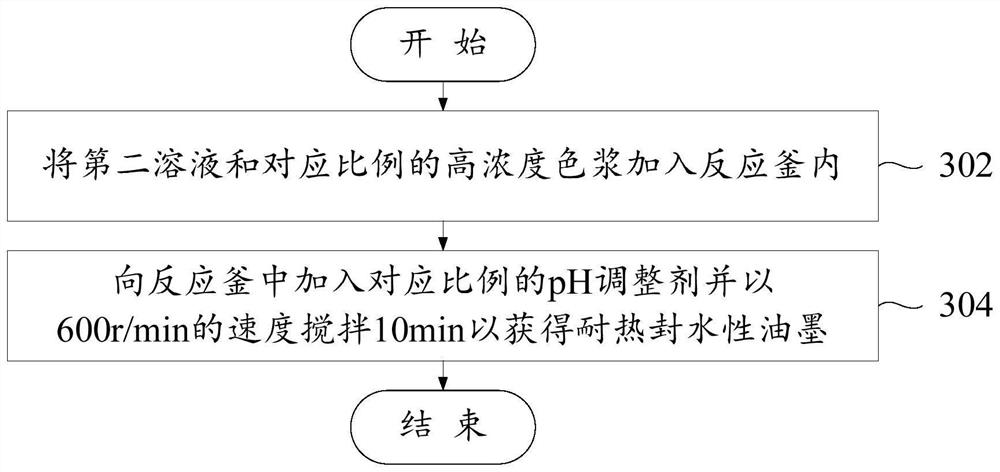

Method used

Image

Examples

Embodiment 1

[0061] According to the first aspect of the present invention, a heat-resistant water-based ink is provided, which includes the following raw material components in weight percentage: 10% to 20% of modified styrene-acrylic resin liquid, modified styrene-acrylic resin The liquid includes the following raw material components in weight percentage: 30% to 40% of deionized water, 8% to 10% of ammonia water, 20% to 30% of crosslinking agent, 0.02% to 0.05% of defoamer, modified styrene-acrylic acid Resin 30%-35%; heat-resistant acrylic emulsion 40%-60%; high-concentration color paste 20%-40%.

[0062] The heat-resistant water-based ink provided by the invention is applied to Tyvek materials. The heat-resistant water-based ink includes modified styrene-acrylic resin liquid, heat-resistant acrylic emulsion and high-concentration color paste, wherein the modified styrene-acrylic The combination of resin liquid and heat-resistant acrylic emulsion can effectively improve the heat-resist...

Embodiment 2

[0066] On the basis of the foregoing examples, this example further illustrates the components of the heat-resistant sealing water-based ink. Further, the modified styrene-acrylic resin liquid is 10% to 20%, and the heat-resistant acrylic emulsion is 40% to 50%. The high-concentration color paste is 20%-40%; the heat-resistant sealing water-based ink also includes the following raw material components in weight percentage: 1%-3% filler; 1%-3% slip agent; 1%-3% wax powder.

[0067]In this embodiment, the heat-resistant sealing water-based ink also includes fillers, slip agents and wax powders, wherein the addition of fillers hardly affects the viscosity of the entire system, but can improve the heat-resistant adhesion of the system, thereby directly improving the heat-resistant Seal the heat resistance of water-based inks. The smoothness and release characteristics of the slip agent make the surface of the heat-resistant water-based ink smooth, making it difficult for the heat-...

Embodiment 3

[0074] On the basis of the foregoing examples, this example further illustrates the components of the heat-resistant sealing water-based ink. Further, the modified styrene-acrylic resin liquid is 10% to 20%, and the heat-resistant acrylic emulsion is 35% to 50%. 20%-40% of high-concentration color paste, 1%-3% of filler, 1%-3% of slip agent, and 1%-3% of wax powder. The heat-resistant water-based ink also includes the following raw material components in weight percentage: 1%-5% of film-forming auxiliary agent; 1%-3% of coupling agent.

[0075] In this embodiment, the heat-resistant water-based ink also includes a film-forming aid and a coupling agent, and the film-forming aid can help the entire system of the heat-resistant water-based ink to better penetrate and wet the substrate (Tyvek material) Uneven contact surface, when the heat-resistant water-based ink penetrates deeper on the substrate, the adhesion of the heat-resistant water-based ink surface will be better after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal stability temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com