Method for improving shrinkage cracking performance of cement-based grouting material

A grouting material, shrinkage cracking technology, used in analytical materials, material inspection products, instruments, etc., can solve the problems of low tensile performance and poor cracking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

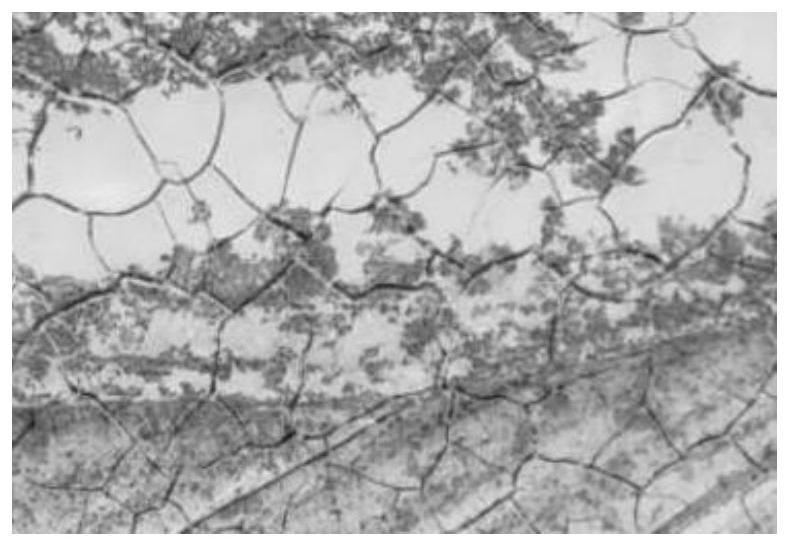

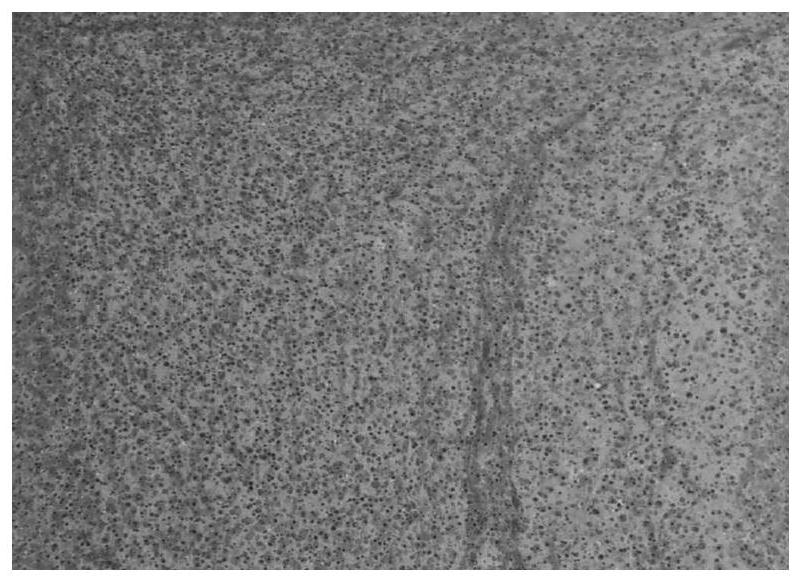

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for improving the shrinkage cracking performance of cement-based grouting materials, comprising the following steps:

[0038] S1, carry out the primary substrate screening test to obtain the primary substrate;

[0039] S2, based on the first-level base material, carry out the screening test of the second-level base material to obtain the second-level base material;

[0040] S3, carry out the fiber reinforcement modification test on the screened secondary base material, and optimize the fiber content to obtain the cement-based grouting dry material;

[0041] S4, adding water with a mass fraction of 9-11% to the cement-based grouting dry material prepared in S3, stirring evenly, and discharging to obtain an improved cement-based grouting material.

[0042] The invention first screens out the cement-based grouting base materials through relevant tests, and then mixes an appropriate amount of expansion agent and an optimized amount of fibe...

Embodiment 2

[0044] This embodiment relates to a method for improving the shrinkage cracking performance of cement-based grouting materials, comprising the following steps:

[0045] S1, performing a first-level base material screening test to obtain a first-level base material, specifically, the first-level base material screening test is a fluidity test and a compressive strength test;

[0046] S2, performing a secondary substrate screening test on the basis of the primary substrate to obtain a secondary substrate; specifically, the secondary substrate screening test is an early shrinkage performance test;

[0047] S3, carry out the fiber reinforcement modification test on the screened secondary base material, optimize the fiber content, and obtain the cement-based grouting dry material;

[0048] S4, adding water with a mass fraction of 9-11% to the cement-based grouting dry material prepared in S3, stirring evenly, and discharging to obtain an improved cement-based grouting material.

...

Embodiment 3

[0059] On the basis of Example 2, the secondary substrate screening test is an early shrinkage performance test, and the expansion agent can improve the early shrinkage performance of the primary substrate. Therefore, the secondary substrate is composed of the primary substrate and a certain amount of expansion agent. Mix composition. Adding an expansion agent accounting for 4% to 10% of the mass of the adhesive material in the primary base material can improve the early shrinkage performance of the primary base material.

[0060] Furthermore, the method for determining the amount of expansion agent is: under the premise of ensuring that the fluidity and compressive strength of the primary base material are satisfied, the expansion agent with an amount of 4% to 10% of the mass of the adhesive material is mixed with the primary base material. Material mixing, compare the effects of different amounts of expansion agent on the early shrinkage performance of the primary base mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com