Chip and cutting method thereof

A cutting method and chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor chip cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

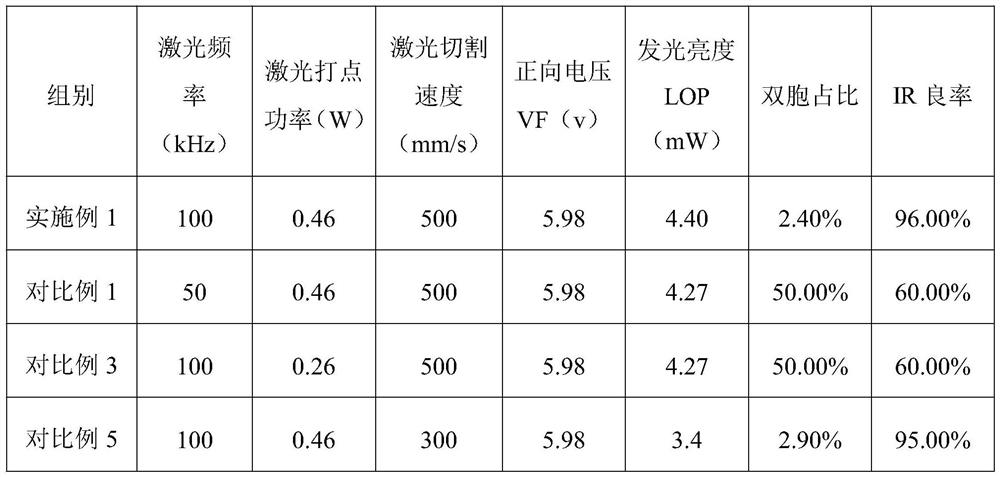

Embodiment 1

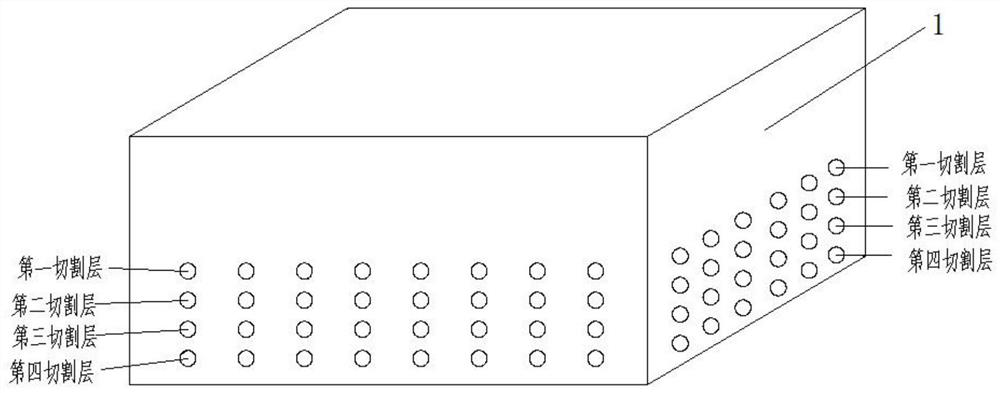

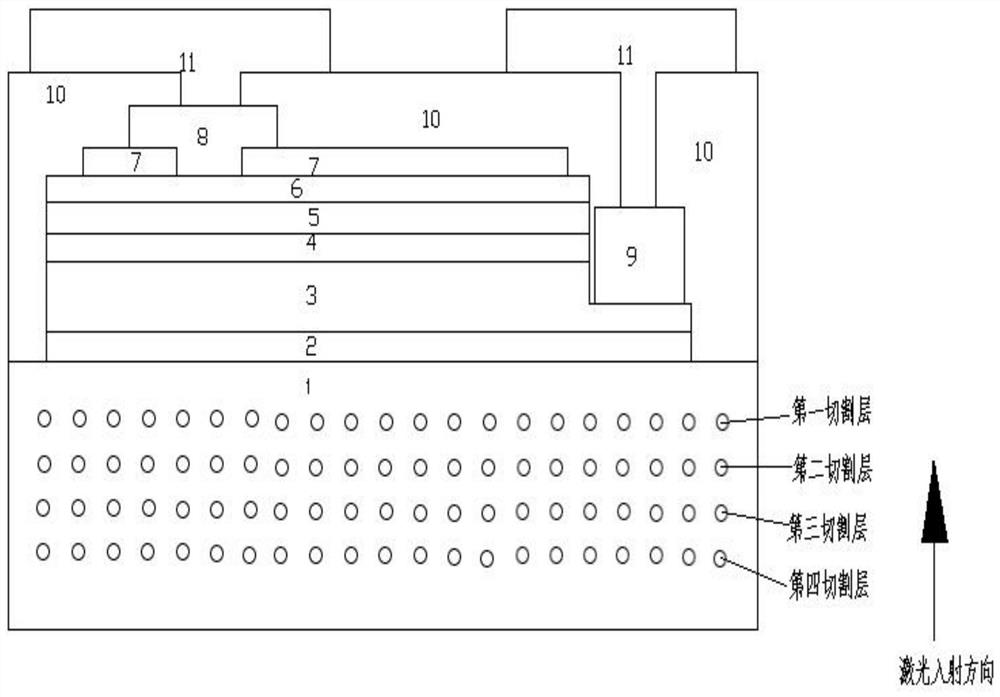

[0029] see Figure 1 to Figure 2 , a chip cutting method, the present embodiment is applied to the cutting of UVC (short-wave ultraviolet) LED chips.

[0030] A chip cutting method, comprising the following steps:

[0031] Step 1. Chip preparation: several chips are prepared on the substrate 1 .

[0032] Step 1.1, grow AlN layer 2, N-type AlGaN layer 3, MQW layer 4, P-type AlGaN layer 5, and P-type GaN layer 6 sequentially on the sapphire substrate 1 through conventional processes to prepare UVC (short-wave ultraviolet) LED epitaxial wafers ;

[0033] Step 1.2, preparing an N electrode layer 9 on the N-type AlGaN layer 3 through an etching process and an electrode contact process on the LED epitaxial wafer;

[0034] Step 1.3: Prepare a current spreading layer 7 with a thickness of 1100A by sputtering or vapor deposition, and carry out alloy treatment on the current spreading layer 7 by means of RTA alloy. process to prepare the pattern of the current spreading layer 7; and...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that in step 2.1, the laser frequency used for the first laser cutting is 90 kHz.

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is that in step 2.1, the laser frequency used for the first laser cutting is 110 kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com