Cooling device based on automation equipment for metal parts processing

A technology of automation equipment and metal parts, which is applied in the field of metal parts processing, can solve the problems of low work efficiency and low cooling efficiency, and achieve the effect of avoiding the blockage of the mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

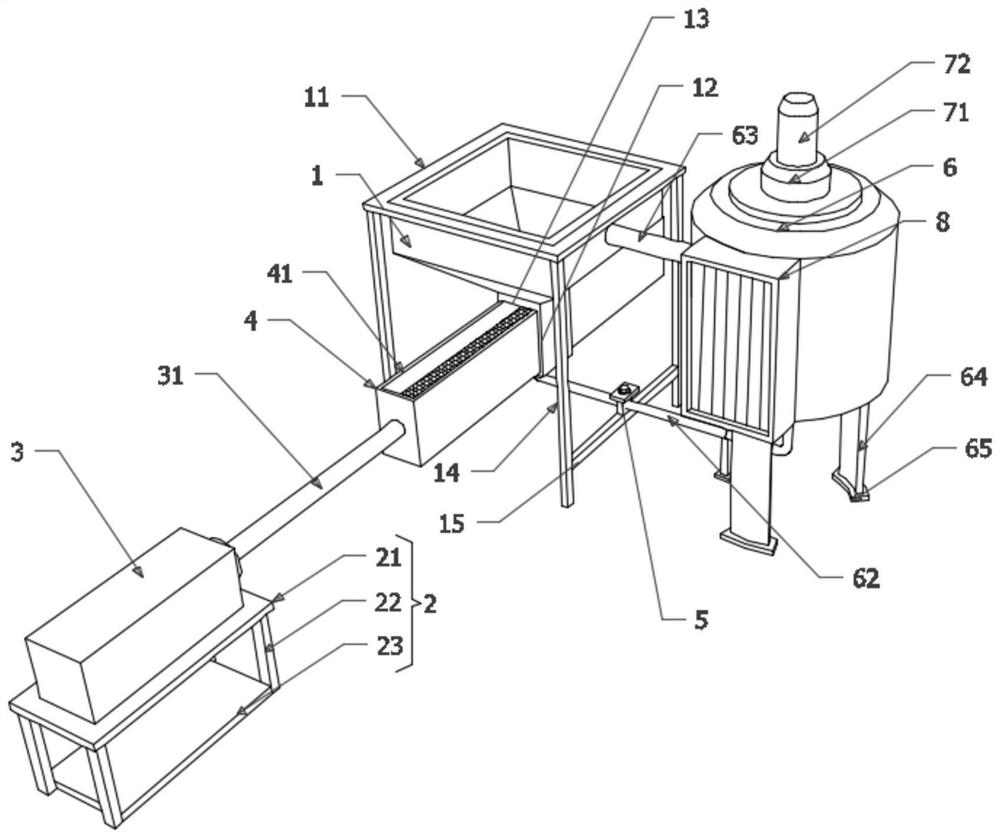

[0040] as attached figure 1 to attach Figure 7 Shown:

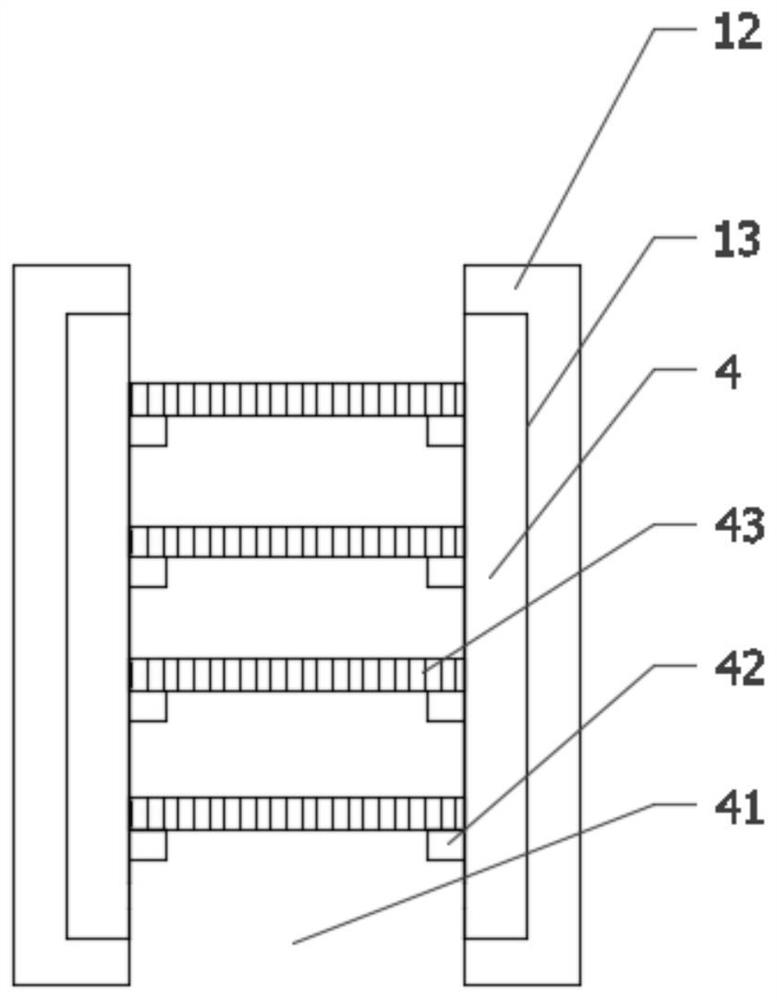

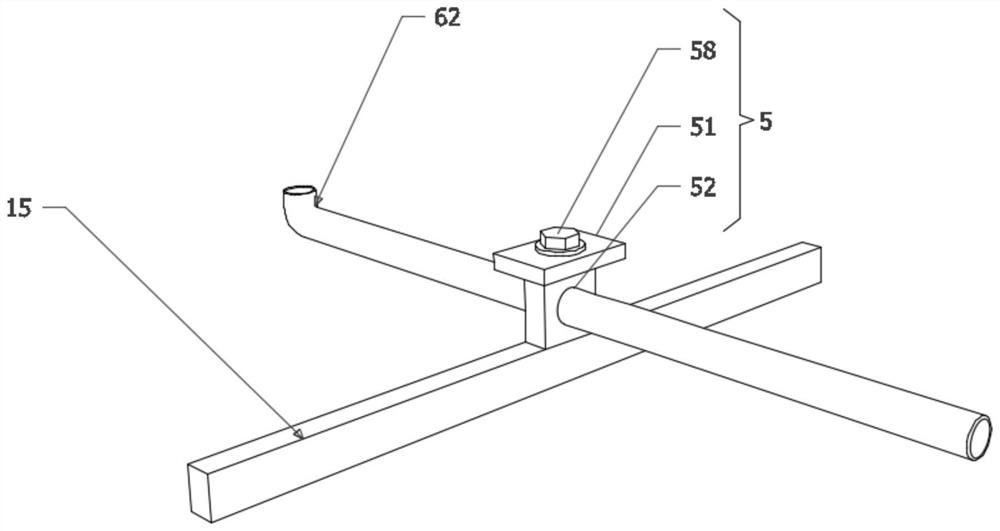

[0041] The cooling device based on the automation equipment for metal parts processing includes an oil collecting pan 1, a support mechanism 2 is arranged on one side of the oil collecting pan 1, a servo cylinder 3 is fixedly installed on the top of the support mechanism 2, and the output end of the servo cylinder 3 is fixedly connected with Telescopic rod 31, a filter frame 4 is fixedly installed at one end of the telescopic rod 31 away from the servo cylinder 3, and the filter frame 4 is slidably installed under the oil collecting pan 1, and a fixing mechanism 5 is arranged under the oil collecting pan 1, and the other end of the oil collecting pan 1 An oil drum 6 is arranged on the side, and a stirring mechanism 7 is fixedly installed in the oil drum 6 .

[0042] Wherein, a ring flange 11 is fixedly installed on the top edge of the oil collecting pan 1, and an oil bucket is fixedly installed on the bottom end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com