Curable composition for flexible hard coat

A curable composition and curable technology, applied in coatings, instruments, optics, etc., can solve problems such as non-stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited to the following examples.

[0124] In addition, in the examples, the apparatus and conditions used for the preparation of the samples and the analysis of the physical properties are as follows.

[0125] (1) Coating with a bar coater

[0126] Device: PM-9050MC manufactured by SMT Co., Ltd.

[0127] Bar: A-Bar OSP-15 manufactured by OSG SYSTEM PRODUCTS Co., Ltd., with a maximum wet film thickness of 15 μm (equivalent to WIREBAR #6.6).

[0128] Coating speed: 4m / min.

[0129] (2) Oven

[0130] Apparatus: Dust-free dryer DRC433FA manufactured by Advantec Toyo Co., Ltd.

[0131] (3) UV curing

[0132] Apparatus: CV-110QC-G manufactured by Heraeus Co., Ltd.

[0133] Lamp: High-pressure mercury lamp H-bulb manufactured by Heraeus Co., Ltd.

[0134] (4) Gel Permeation Chromatography (GPC)

[0135] Apparatus: HLC-8220GPC manufacture...

manufacture example 1

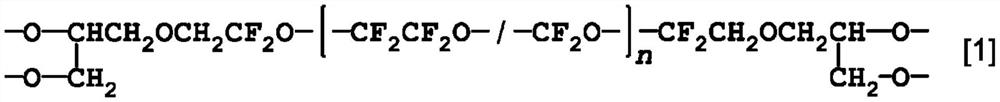

[0173] [Production Example 1] Production of Surface Modifier SM

[0174] 1.19 g (0.5 mmol) of PFPE1, 0.52 g (2.0 mmol) of BEI, 0.017 g (0.01 times the total mass of PFPE1 and BEI) of DOTDD, and 1.67 g of MEK were charged into the spiral tube. This mixture was stirred at room temperature (about 23° C.) for 24 hours using a Starer Chip to obtain a 50% by mass MEK solution of the surface modifier SM as the target compound. The weight average molecular weight: Mw of the obtained SM measured in terms of polystyrene by GPC was 3000, and the degree of dispersion: Mw (weight average molecular weight) / Mn (number average molecular weight) was 1.2.

Embodiment 1~ Embodiment 3、 comparative example 1~ comparative example 4

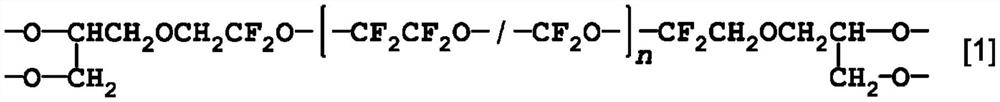

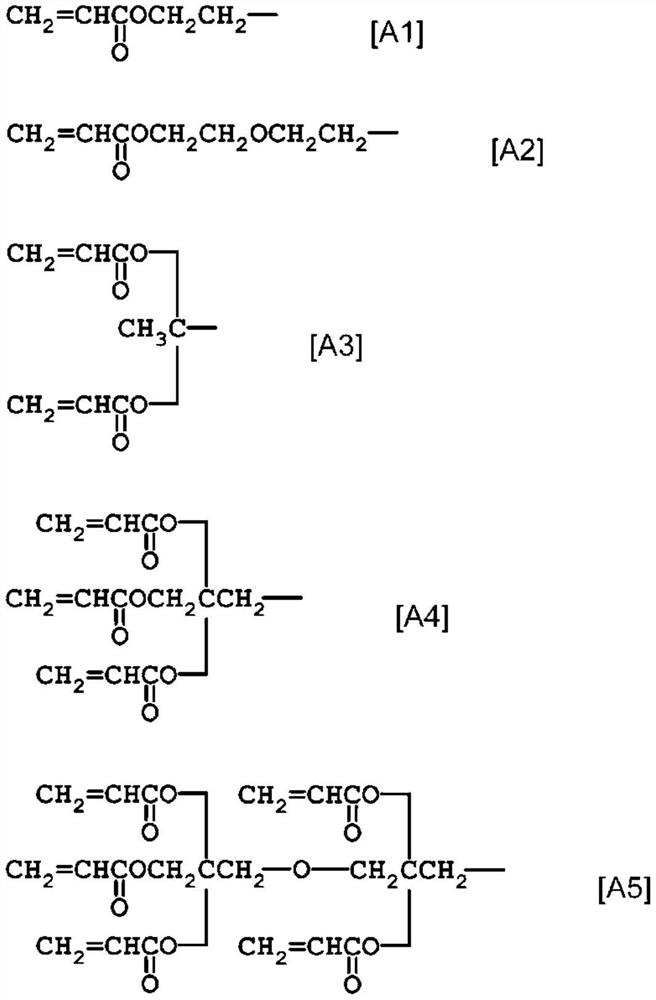

[0176] The following components were mixed as described in Table 1 to prepare a curable composition having a solid content concentration described in Table 1. In addition, here, solid content means components other than a solvent. In addition, in Table 1, [part] shows [part by mass]. This curable composition was coated on an A4 size double-sided easy-adhesive PET film [Toray Co., Ltd. Lumirror (trademark registration) U403, thickness 100 μm] with a bar coater to obtain a coating film. The coating film was dried in an oven at 120° C. for 3 minutes to remove the solvent. The resulting film was irradiated with an exposure dose of 1200mJ / cm in air 2 By exposing to UV light, a hard coat film having a hard coat layer (cured film) having a layer (film) thickness of about 2 μm was produced.

[0177] Scratch resistance, stretchability, buckling resistance, pencil hardness, and antifouling properties of the obtained hard coat film were evaluated. The evaluation methods of scratch re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com