Tower type continuous flow reactor and application thereof

A reactor and tower technology, applied in the field of tower continuous flow reactors, can solve the problems of large footprint and complicated operation of the reactor, and achieve the effects of convenient regulation, the same stirring rate and improving the reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

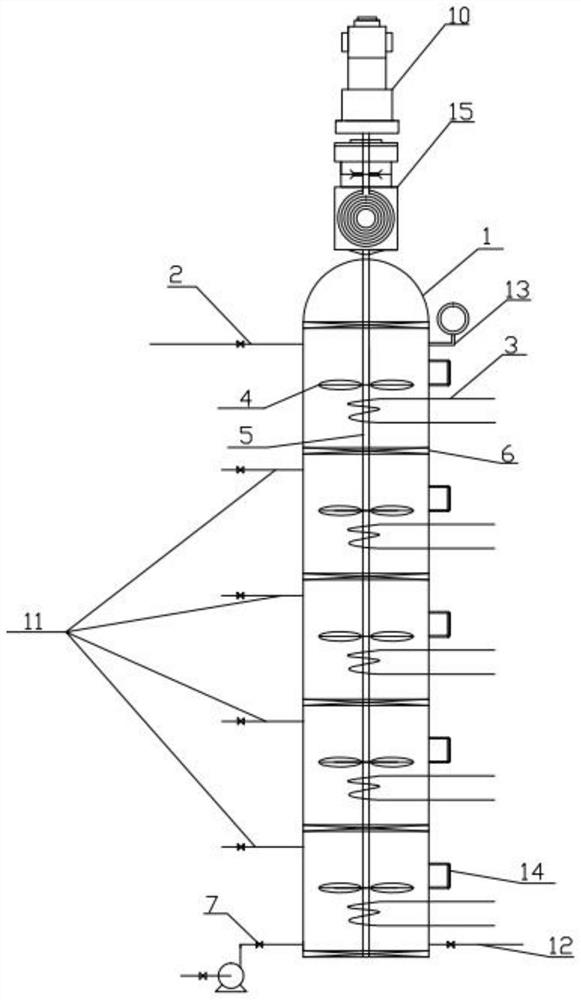

[0024] Example: Control Figure 1-2

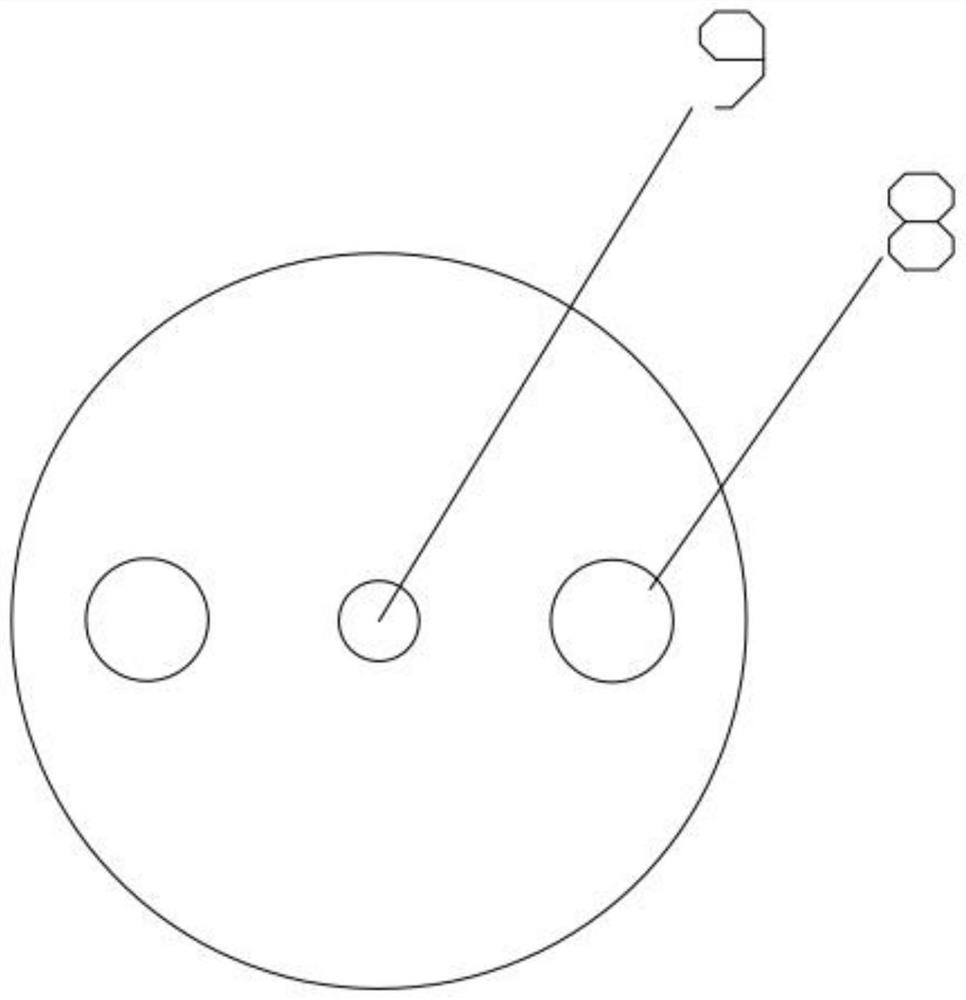

[0025] A tower-type continuous flow reactor, comprising a reactor 1 in a tower structure, a motor 10 is arranged on the top of the reactor 1, and a stirring shaft 5 is connected to the motor 10; a plurality of partitions are arranged in the reactor 1 at intervals from bottom to top Plate 6, divider 6 divides reactor 1 into several reaction chambers, and each divider 6 is provided with a plurality of lifting holes 8 and an axis hole 9 for passing through the stirring shaft 5, and the plurality of The shaft holes 9 on the dividing plate 6 are located on the same vertical line. The lower end of the stirring shaft 5 extends into the reactor 1 from the top of the reactor 1, and extends to the bottom of the reactor 1 through the shaft hole 9 on the dividing plate 6; in the reactor 1, on the stirring shaft 5 in each reaction chamber Each is fixed with at least one layer of stirring blades 4, and the ratio of the outer diameter of the stirring b...

Embodiment 1

[0033] Such as Figure 1-2 As shown, a tower type continuous flow reactor, the reactor is a tower structure, 4 partitions are arranged in the reactor, and the reactor is divided into five reaction chambers by 4 partitions, and each partition is provided with There are two lifting holes and a shaft hole, the diameter of the lifting hole is 25mm, and the diameter of the shaft hole is 140mm. The inner diameter of the tower of the reactor is 1 meter, and the height of each reaction chamber is 0.5 meters.

[0034] A coil heat exchanger is installed in each reaction chamber, and the heat exchange area of the coil heat exchanger is 1m 2 The temperature in each reaction chamber is controlled by adjusting the flow rate of the heat exchange medium in the coil heat exchanger. Each reaction chamber is provided with a sampling port and a temperature measuring port, and a valve is provided at the sampling port.

[0035] A motor is provided on the top of the reactor, and the motor is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com