Food container and manufacturing method thereof

A technology for food containers and lids, which is applied in the field of food containers and their production, can solve the problems of being easily depressed or bulging under pressure, slow to open and fasten, and affecting the appearance, and achieves convenience in use, firmness, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

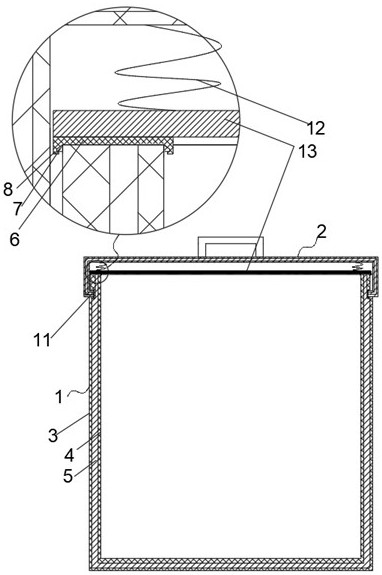

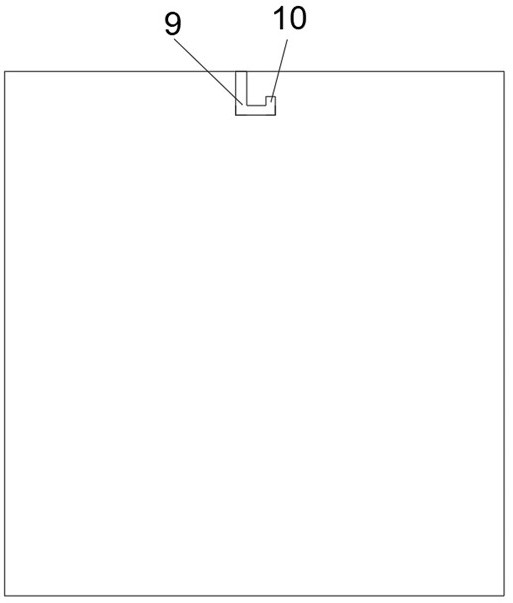

[0023] Such as figure 1 and figure 2 The shown food container includes a cylinder body 1, a cover body 2, an outer body body 3, an inner body body body 4, a foam heat insulation layer 5, a heat insulation ring 6, a tapered protrusion 7, an L-shaped protrusion 8, L-shaped guide groove 9, clamping groove 10, clamping block 11, spring 12 and heat insulation sealing plate 13.

[0024] Both the cylinder body 1 and the cover body 2 include an outer shell 3 and an inner shell 4, and a polyurethane heat insulation layer is filled between the outer shell 3 and the inner shell 4; the end faces of the outer shell 3 and the inner shell 4 are fixed with heat-insulating rubber ring.

[0025] The inner and outer sides of the cylinder body 1 and the cover body 2 are convexly formed with conical bumps 7, and the heat-insulating rubber ring is formed with L-shaped snap-in protrusions 8 that cooperate with the tapered bumps 7, thereby clamping the heat-insulating rubber ring, and The heat in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap