Space rod piece structure vibration reduction device and method

A vibration damping device, space rod technology, applied in the direction of shock absorber, friction shock absorber, shock absorber, etc., can solve the problem of reducing the attitude stability of the spacecraft platform, affecting the normal operation of the spacecraft, and the vibration of the space rod structure, etc. problem, to achieve the effect of fast and stable structure of space rod, simple structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

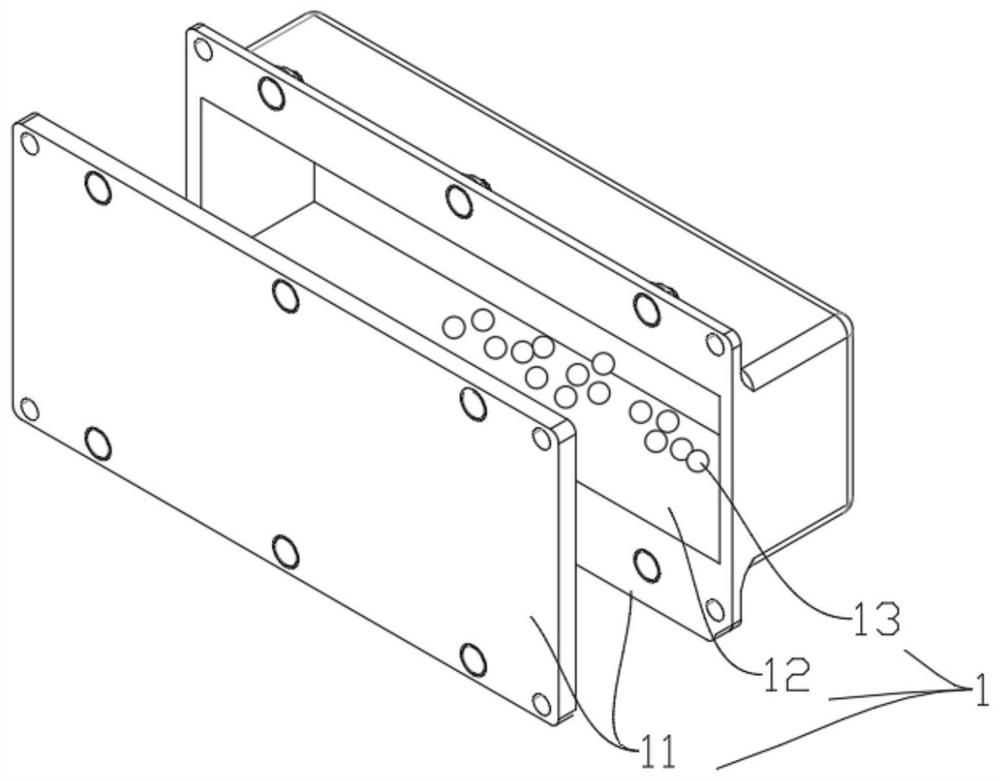

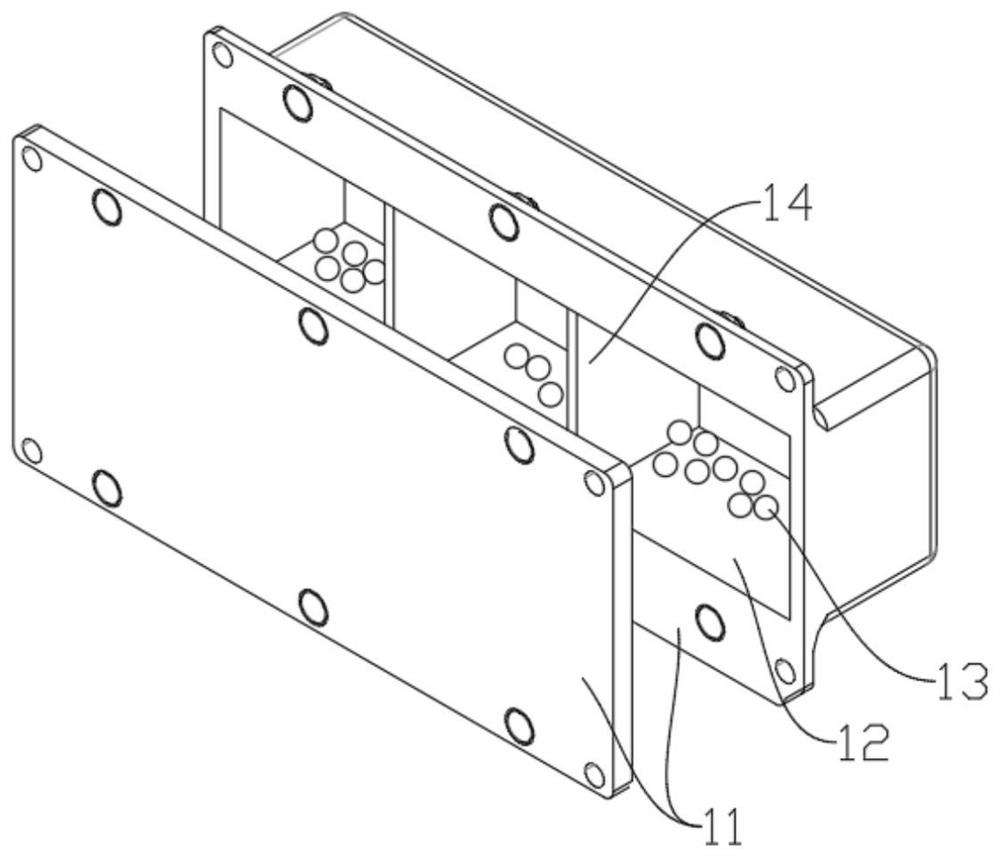

[0039] Such as Figure 1-2 As shown, the present invention discloses a space bar structure vibration damping device, which includes several particle dampers 1 for installation on the space bar structure 2, and the particle damper 1 includes a closed cavity 12 inside. Shell 11 and several damping particles 13 built in the cavity 12 to form a particle medium contact stress network, when the vibration frequency of the space bar structure 2 is less than 200Hz, the restitution coefficient of the damping particles 13 is 0.4-0.7, and the friction coefficient is 0.05- 0.3, when the vibration frequency of the space member structure 2 is 200-1000 Hz, the restitution coefficient of the damping particles 13 is 0.1-0.4, and the friction coefficient is 0.3-0.55.

[0040] When the vibration frequency of the space bar structure 2 is less than 200Hz, the filling rate of the damping particles 13 is set between 85% and 90%; when the vibration frequency of the space bar structure 2 is 200-1000Hz,...

Embodiment 2

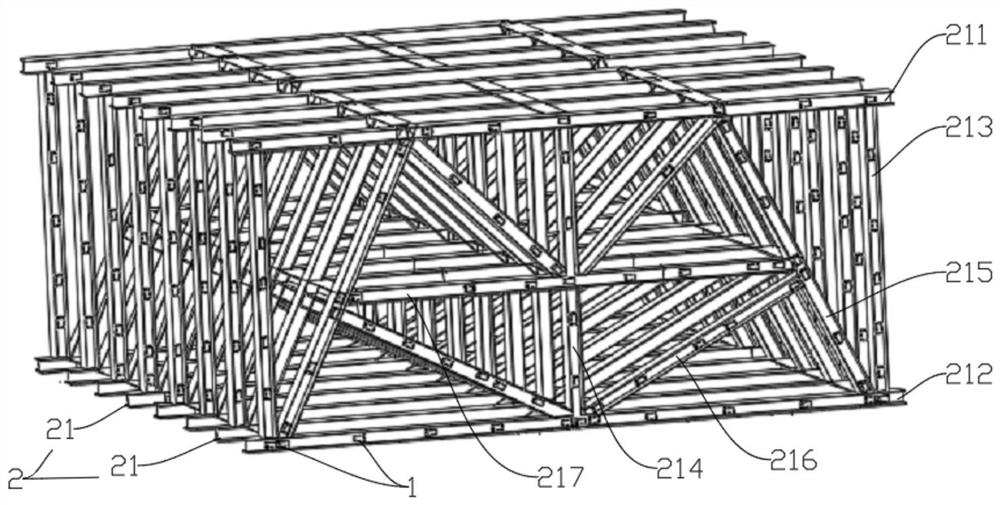

[0058] On the basis of the first embodiment above, as image 3 As shown, the space member structure 2 is composed of several parallel and spaced planar member structures 21 connected to each other. 211 and the lower chord 212 are affixed to each other to form the first vertical bar 213 of a rectangular frame, one end is fixed to the center of the upper chord 211 and the other end is fixed to the second vertical bar 214 at the center of the lower chord 212, and the second vertical bar 214 is separately arranged on the second vertical bar. 214 on both sides and one end is affixed with the upper chord 211 and the other end is affixed with the lower chord 212, the first oblique rod 215, the transverse web rod 217 with both ends affixed to the first oblique rod 215, and several second oblique rods. Rod 216 , one end of the second slanting rod 216 is fixedly connected to the first slanting rod 215 , and the other end is fixedly connected to the second vertical rod 214 .

[0059] Th...

Embodiment 3

[0061] On the basis of the above-mentioned embodiment two, as Figure 4 As shown, a base 3 is provided at the bottom of the space bar structure 2 , and several vibration isolators 4 are set between the space bar structure 2 and the base 3 .

[0062] The vibration isolator 4 is preferably a rubber vibration isolator, which is combined with the space bar structure 2 to form a vibration isolation floating raft. When vibration occurs, the particle damper 1 located on the space bar structure 2 can consume the vibration energy on the structure in advance Partly, the transmission of vibration energy to the vibration isolator 4 is reduced, the high-frequency standing wave problem existing in the vibration isolator 4 is effectively improved, the vibration isolation efficiency of the vibration isolator 4 is improved, and the overall vibration isolation effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com