Belt conveyor fault diagnosis method based on sound signals

A belt conveyor and sound signal technology, which is applied in the field of belt conveyor fault diagnosis based on sound signals, can solve the problem of high fault detection accuracy requirements, increased labor risks for inspectors, and many belt conveyor fault detection points, etc. problems, to achieve the effect of fast detection speed, high real-time performance, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

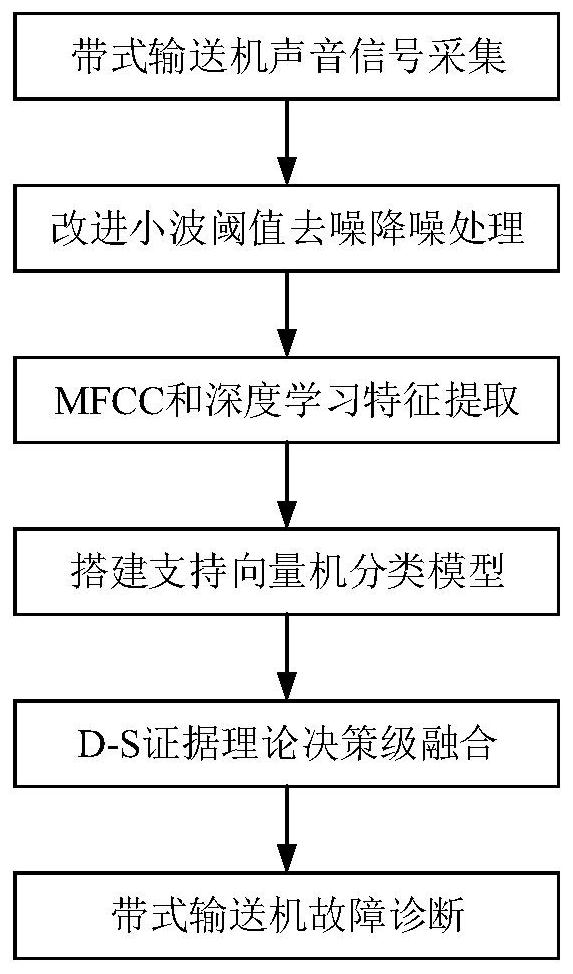

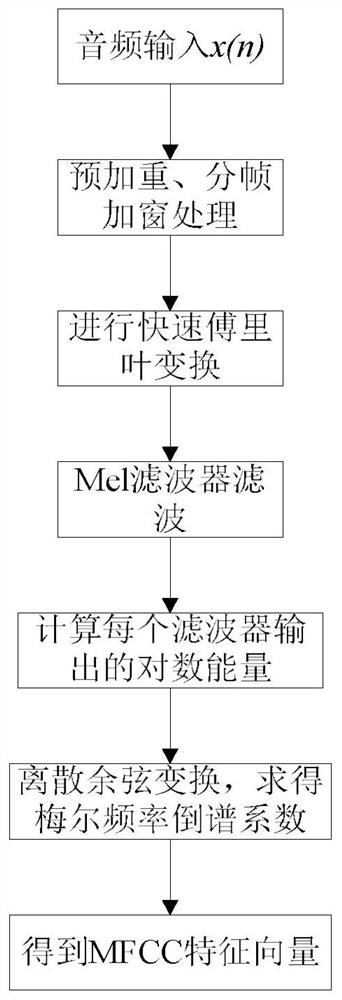

[0079] Such as figure 1 Shown, a kind of belt conveyor fault diagnosis method based on sound signal of the present invention comprises the following steps:

[0080] S1, collecting the sound signal of the belt conveyor:

[0081] Specifically, in step S1, the sound signal of each running state when the belt conveyor is working is collected with a sampling frequency of 48kHz and a sampling point of 4096 using the sound collection device; the running state of the belt conveyor includes normal state and idler failure, Belt tear fault, drum fault three fault states;

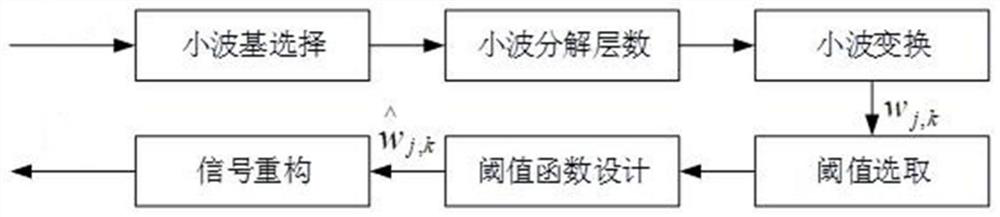

[0082] S2. Perform improved wavelet threshold denoising processing on the collected sound signal. The denoising processing process includes wavelet base selection, decomposition layer number selection, threshold selection and threshold function improvement, and signal reconstruction;

[0083] Specifically, in step S2, the denoising process includes the following steps:

[0084] S2.1. Select a wavelet base db6 with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com