Safe operation supervision system for orchard weeding robot

A technology for safe operation and supervision system, applied in the direction of instruments, data processing applications, forecasting, etc., can solve the problems of inability to detect the information security performance of weeding robots, the efficiency of weeding robots cannot be guaranteed, and the security of user information cannot be guaranteed. , to achieve high accuracy, comprehensive monitoring parameters, and avoid unqualified results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

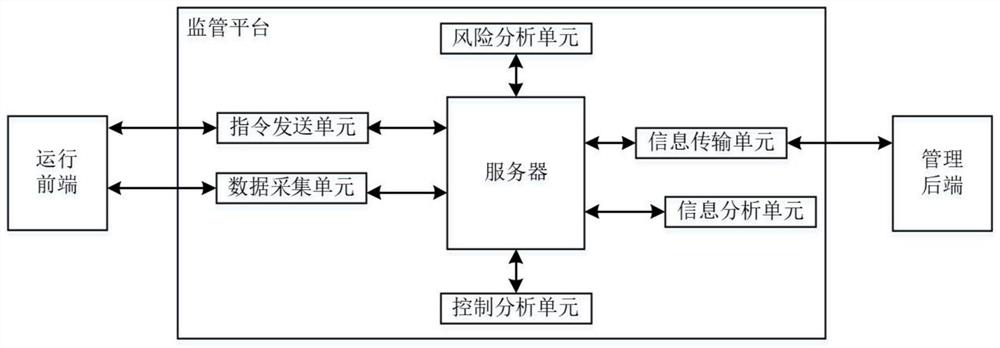

[0041] Such as figure 1 As shown, a safe operation supervision system for orchard weeding robots includes a supervision platform, an operation front-end, and a management back-end. For intelligent robots with cameras, the management backend includes intelligent terminal equipment, a server is set in the supervision platform, and the two-way communication connection of the server includes a risk analysis unit, an instruction sending unit, a control analysis unit, an information transmission unit, and an information analysis unit;

[0042] The historical operation information of the intelligent robot is collected through the data acquisition unit, and the operation information is sent to the server. The historical operation information of the intelligent robot includes deviation data, buffer data and error data. The deviation data is the deviation value of the displacement during the historical operation process of the intelligent robot , the buffer data is the buffering time of...

Embodiment 2

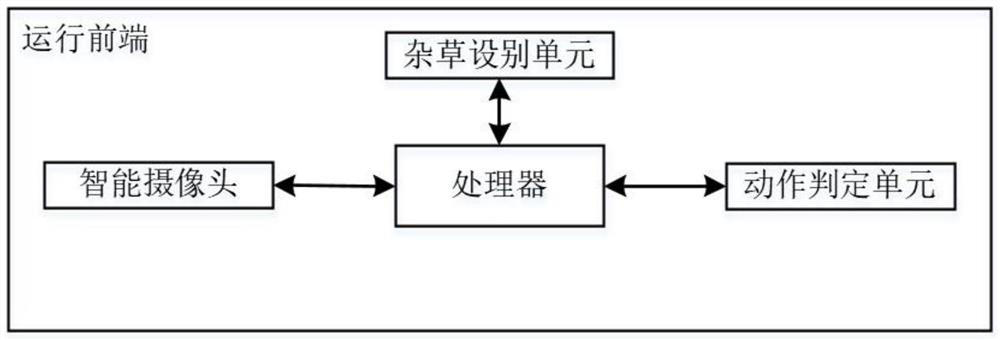

[0059] see figure 2 As shown, a safe operation supervision system for orchard weeding robots is used in the operation front end, including a smart camera, a weed identification unit, a processor and an action determination unit;

[0060] Set the weeds in the orchard through the weed identification unit, collect the shape and color of the leaves corresponding to the planting varieties in the orchard, and mark the corresponding leaves as planting plants, mark plants other than planting plants as plant weeds, and Send the plant weeds and planting plants to the processor; the processor generates the acquisition signal after receiving the plant weeds and planting plants and sends the acquisition signal to the smart camera, the smart camera takes real-time pictures, and sends the pictures of the real-time orchard environment to the processing The processor analyzes the real-time orchard environment picture according to the plant weeds and planting plants, color-marks the plants and...

Embodiment 3

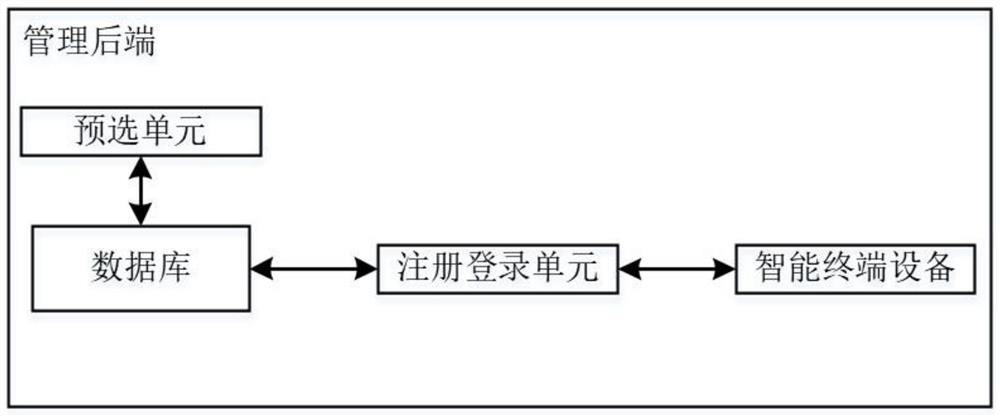

[0062] see image 3 As shown, a safe operation supervision system for an orchard weeding robot is used for managing the back end, including a pre-selection unit, a database, a registration and login unit, and an intelligent terminal device; the intelligent terminal device includes a smart tablet computer or a smart phone;

[0063]The management personnel send the information of the real-time registered management personnel to the registration and login unit through the smart terminal device. After the registration and login unit receives the information of the real-time registered management personnel, it registers the management personnel and transmits the registered management personnel information to the database Storage, the information of the manager includes the manager's name, entry time and mobile phone number;

[0064] After the database receives the successfully registered management personnel information, it generates a pre-selection signal and sends the pre-selecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com