Preparation method of copper hydroxide two-dimensional nanocomposite based on iron-based dopamine supramolecular modification

A nanocomposite material, copper hydroxide technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve toxicity, high cost of Pt-based catalytic materials, single synthesis cost of precursors, etc. problems, to achieve the effect of simple equipment, excellent stability, and excellent limiting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

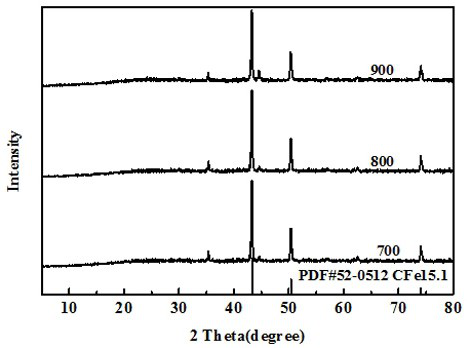

[0062] a 2D Cu(OH)2 The synthesis method of @PDA-Fe anode material includes the following steps:

[0063] (1) Weigh 720 mg CuCl 2 and 800 mg of PEG were dissolved in 400 mL of deionized water and stirred for 30 min to fully dissolve;

[0064] (2) Slowly add 3.2 mL of 6 M NaOH solution dropwise to the solution of step (1) and continue to stir at room temperature for 30 minutes, then let it stand to form a precipitate;

[0065] (3) The precipitate obtained in step (2) is washed with deionized water and centrifuged, and then freeze-dried;

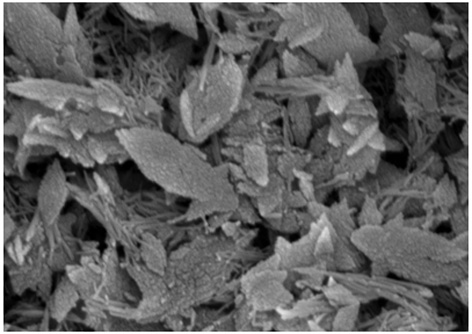

[0066] (4) The product obtained after drying was added to deionized water, sonicated for 3 h, and then dried at 60 °C to obtain Cu(OH) 2 Nanosheets;

[0067] (5) 100 mg Cu(OH) 2 The nanosheets were dispersed in 20 mL of absolute ethanol and sonicated for 30 min to obtain Cu(OH) 2 Dispersions;

[0068] (6) 189.6 mg of dopamine and 80.8 mg of Fe(NO) 3 ·9H 2 O (molar ratio of 5:1) was dissolved in 20 mL of absolute ethanol;

[0069] (7)...

Embodiment 2

[0073] a 2D Cu(OH)2 The synthesis method of @PDA-Fe anode material includes the following steps:

[0074] (1) Weigh 720 mg CuCl 2 and 800 mg of PEG were dissolved in 400 mL of deionized water and stirred for 30 min to fully dissolve;

[0075] (2) Slowly add 3.2 mL of 6 M NaOH solution dropwise to the solution of step (1) and continue to stir at room temperature for 30 minutes, then let it stand to form a precipitate;

[0076] (3) The precipitate obtained in step (2) is washed with deionized water and centrifuged, and then freeze-dried;

[0077] (4) The product obtained after drying was added to deionized water, sonicated for 3 h, and then dried at 60 °C to obtain Cu(OH) 2 Nanosheets;

[0078] (5) 100 mg Cu(OH) 2 The nanosheets were dispersed in 20 mL of absolute ethanol and sonicated for 30 min to obtain Cu(OH) 2 Dispersions;

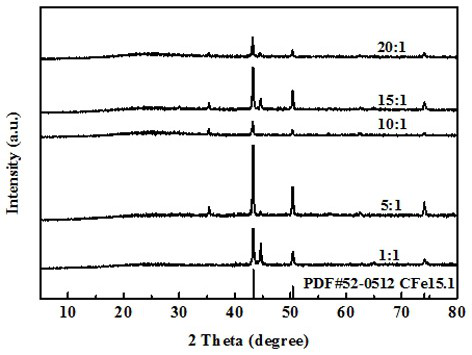

[0079] (6) Combine dopamine and 80.8 mg Fe(NO) 3 ·9H 2 O was dissolved in 20 mL absolute ethanol in molar ratios of 1:1, 5:1, 10:1, 15:1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com