Clamping device and cutting method for half-side pipe laser cutting

A laser cutting and clamping device technology, which is applied in laser welding equipment, applications, household appliances, etc., can solve the problems of complicated half-pipe positioning device, high manufacturing cost, and unreliable positioning, so as to achieve simple and reasonable structure and ensure cutting quality , The effect of firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

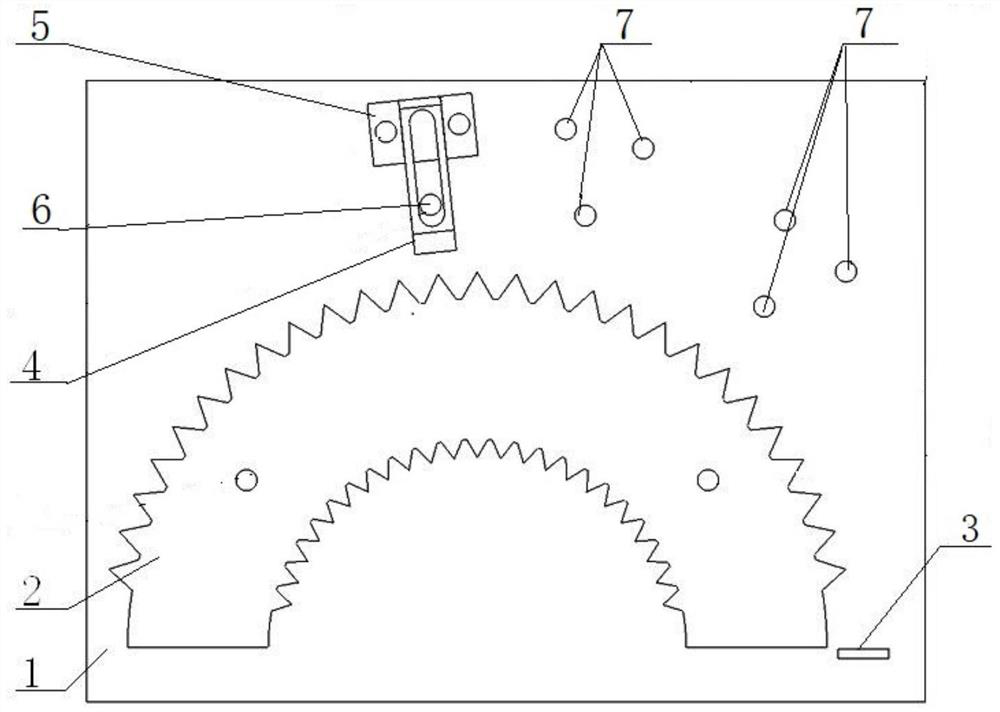

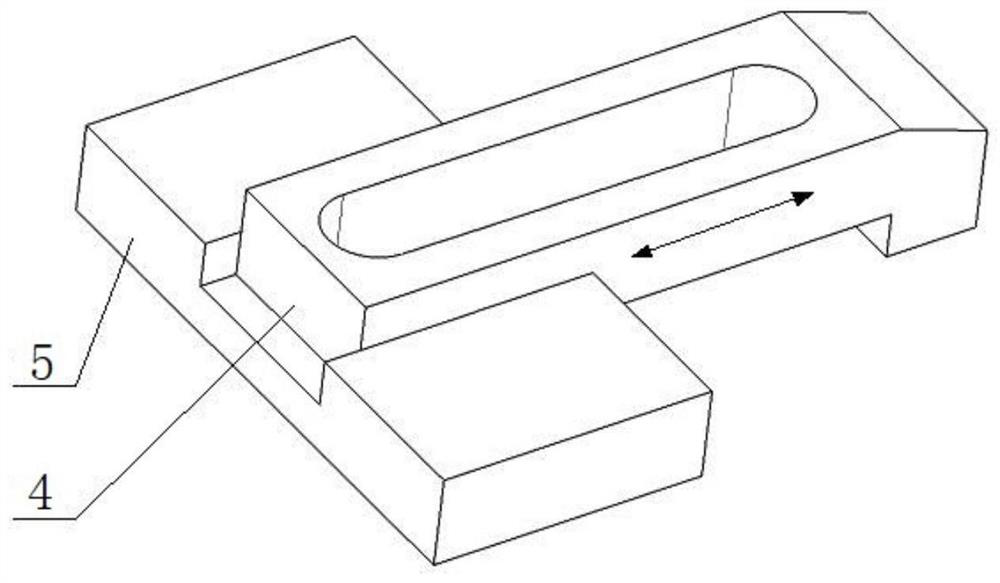

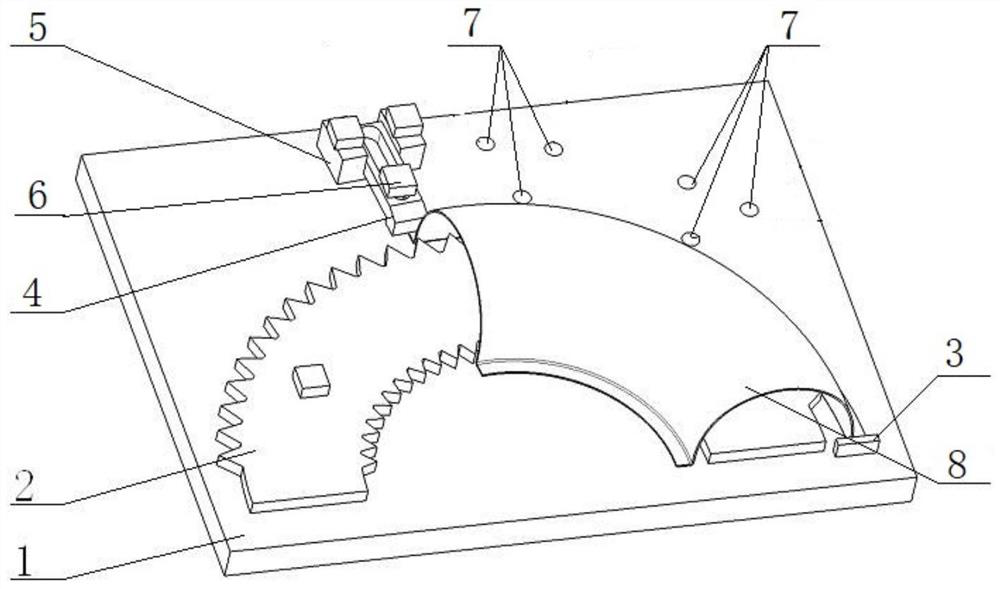

[0023] like figure 1 As shown, this embodiment provides a clamping device for laser cutting of half-side pipes, including a fixed plate 1 and a positioning plate 2 installed on the fixed plate 1, a stopper 3, and a pressing mechanism. The positioning plate 2 is The arc-shaped plate adapted to the diameter of the inner hole of the half pipe to be cut, the peripheral edge of the positioning plate 2 is zigzag, the half pipe cover to be cut is arranged outside the positioning plate 2 during assembly, the positioning plate 2 and the half pipe to be cut line contact between them; the stopper 3 is arranged on one end of the positioning plate 2 for blocking the end wall of the half pipe after assembly; After assembly, the pressure block 4 that expands and expands in the radial direction of the half pipe, the pressure blocking mechanism also includes a pad 5 and a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com