Ternary precursor with core-shell structure and preparation method and application thereof

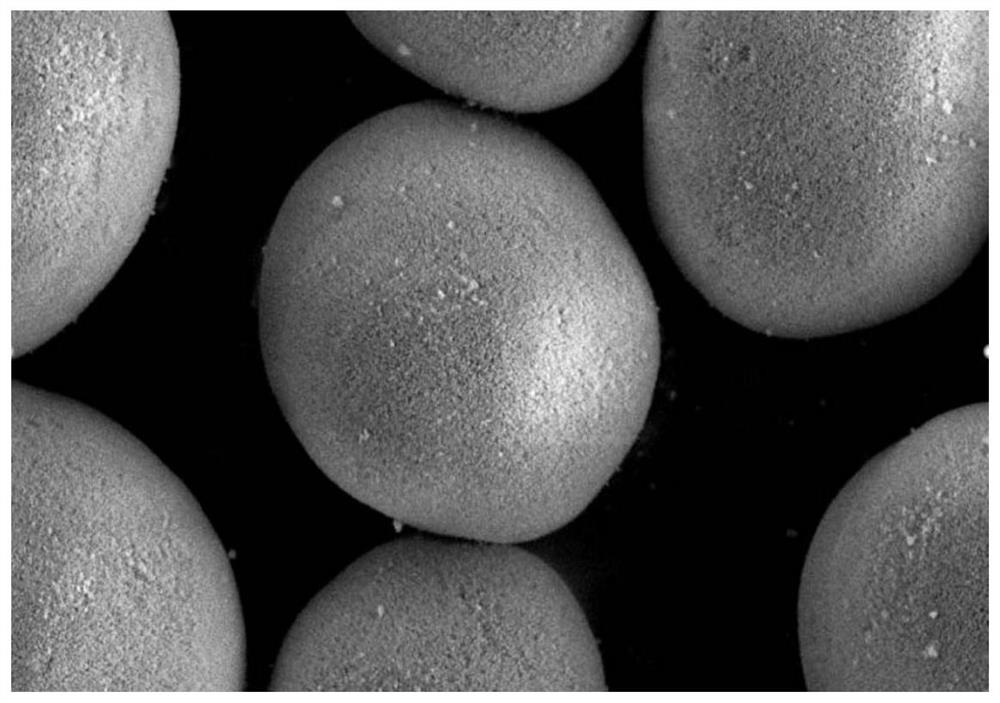

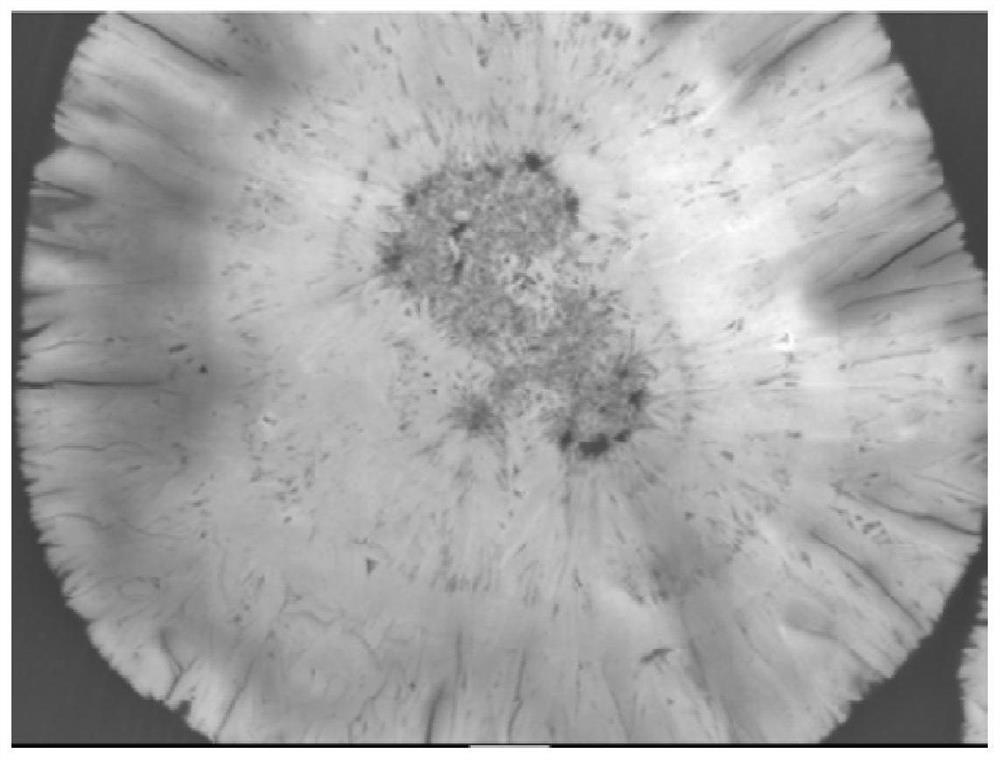

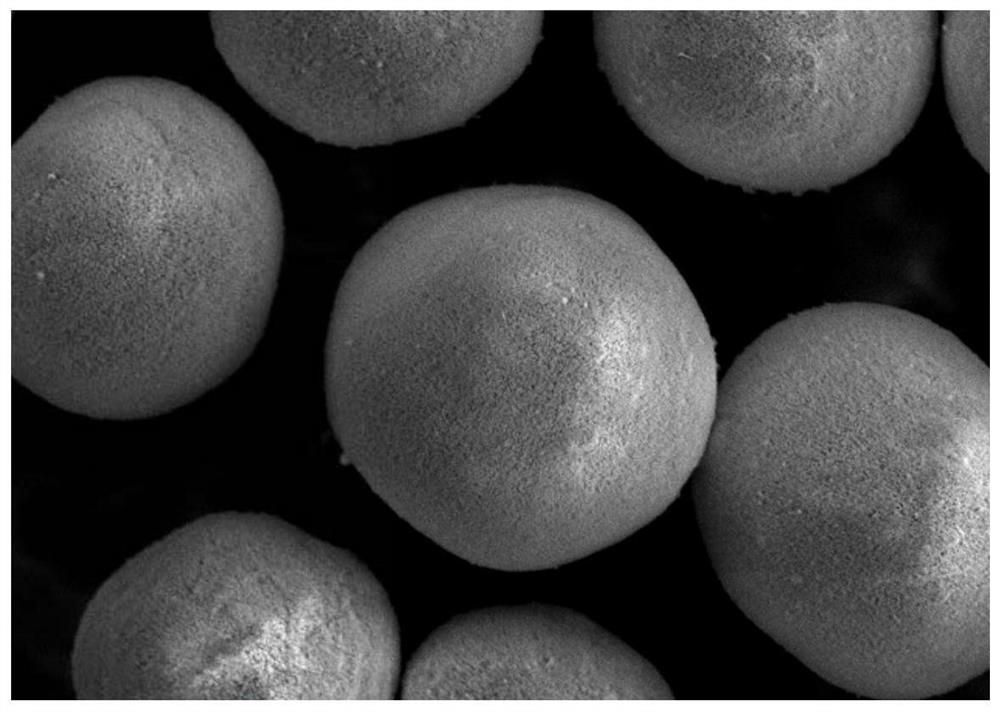

A core-shell structure and precursor technology, applied in structural parts, chemical instruments and methods, electrical components, etc., can solve product S content control, specific surface area and production cost constraints, affect the electrochemical performance of ternary materials, and process stability Poor properties and other problems, to avoid low tap density, excellent electrochemical performance, improve sphericity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] According to one aspect of the present invention, the present invention relates to a method for preparing a ternary precursor of a core-shell structure, comprising the following steps:

[0052] (a) The mixture of the first mixed salt, the first precipitating agent, the first complexing agent and the first bottom liquid undergoes a co-precipitation reaction to obtain the inner core of the ternary precursor;

[0053] (b) The inner core of the ternary precursor and the mixture of the second mixed salt, the second precipitating agent, the second complexing agent and the second bottom liquid carry out a co-precipitation reaction;

[0054] The D50 particle size of the core of the ternary precursor is 30% to 50% of the D50 particle size of the ternary precursor with the core-shell structure;

[0055] The first mixed salt is nickel salt, cobalt salt and manganese salt;

[0056] The second mixed salt is nickel salt, cobalt salt and manganese salt;

[0057] The first precipitat...

Embodiment 1

[0109] A preparation method of a ternary precursor of a core-shell structure, comprising the following steps:

[0110] (a) Prepare a sulfate solution with a nickel, cobalt, and manganese molar ratio of 6:1:3, the sum of the concentrations of nickel ions, cobalt ions, and manganese ions is 1.5mol / L; prepare sodium hydroxide with a concentration of 12mol / L solution; prepare an ammonia solution with a concentration of 5mol / L; add a special reaction bottom liquid to the reaction kettle in advance, the reaction bottom liquid is sodium hydroxide and ammonia solution, and the pH is 11.5, and the ammonium root concentration is 5g / L;

[0111] (b) Put the above nickel, cobalt, manganese sulfate solution, sodium hydroxide and ammonia solution into the reaction kettle in parallel, the temperature is controlled at 60°C, the pH is controlled at 11.50, the ammonium root concentration is 5g / L, and the rotation speed is 200r / min, the whole reaction is carried out under nitrogen protection; wh...

Embodiment 2

[0117] A preparation method of a ternary precursor of a core-shell structure, comprising the following steps:

[0118] (a) Prepare a sulfate solution with a nickel, cobalt, and manganese molar ratio of 6:1:3, the sum of the concentrations of nickel ions, cobalt ions, and manganese ions is 5mol / L; prepare a sodium hydroxide solution with a concentration of 12mol / L ; Prepare an ammonia solution with a concentration of 5mol / L; add a special reaction bottom solution to the reaction kettle in advance, the reaction bottom solution is sodium hydroxide and ammonia solution, and the pH is 11.5, and the ammonium root concentration is 9g / L;

[0119] (b) Put the above-mentioned sulfate solution of nickel, cobalt and manganese, sodium hydroxide and ammonia solution into the reaction kettle; the temperature is controlled at 60°C, the pH is controlled at 11.50, the rotating speed is 200r / min, and the whole reaction is under nitrogen protection Carry out below; Wherein, the ratio of the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com